Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2 results about "Dental arch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The dental arches are the two arches (crescent arrangements) of teeth, one on each jaw, that together constitute the dentition. In humans and many other species, the superior (maxillary or upper) dental arch is slightly larger than the inferior (mandibular or lower) arch, so that in the normal condition the teeth in the maxilla (upper jaw) slightly overlap those of the mandible (lower jaw) both in front and at the sides. The way that the jaws, and thus the dental arches, approach each other when the mouth closes, which is called the occlusion, determines the occlusal relationship of opposing teeth, and it is subject to malocclusion (such as crossbite) if facial or dental development was imperfect.

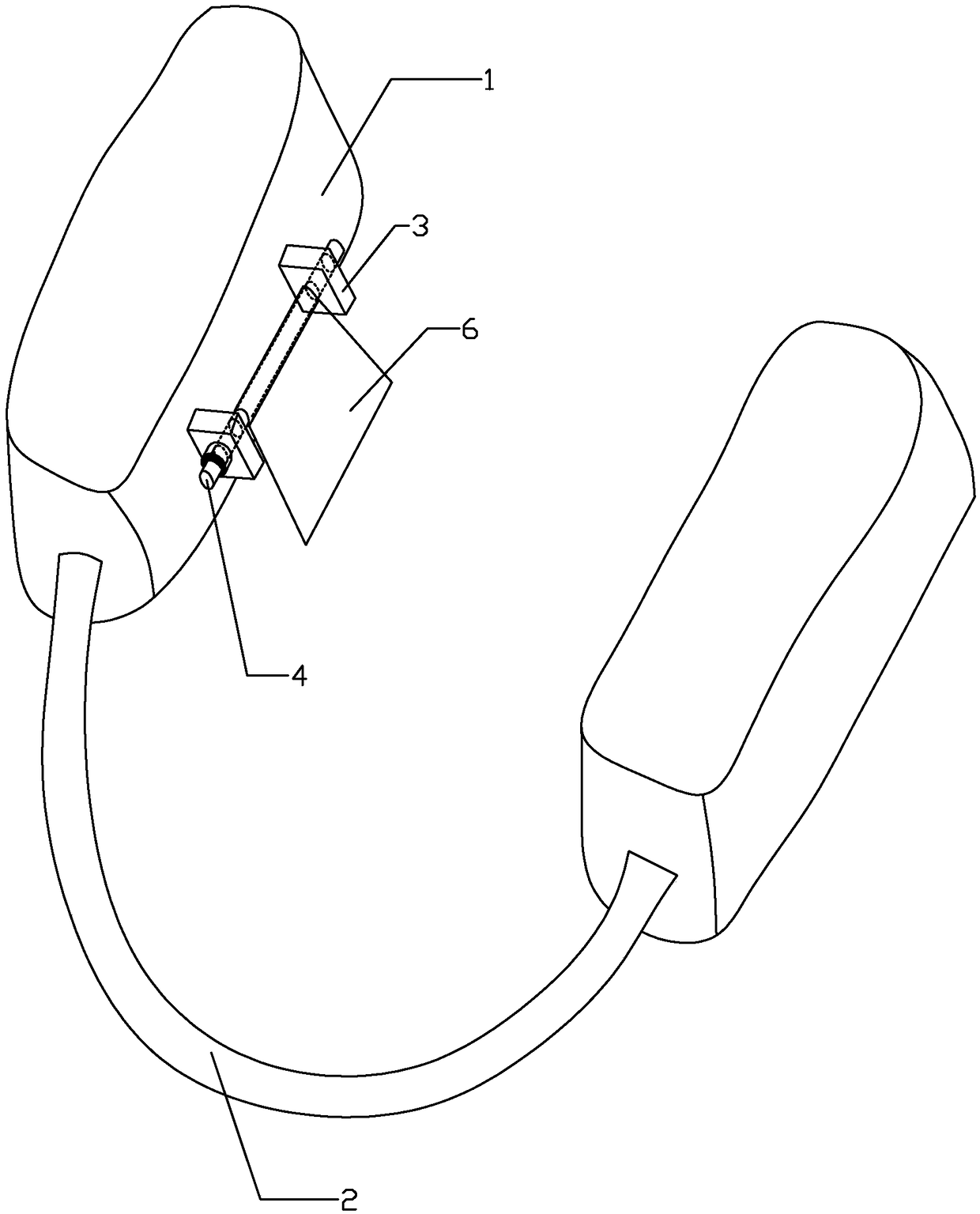

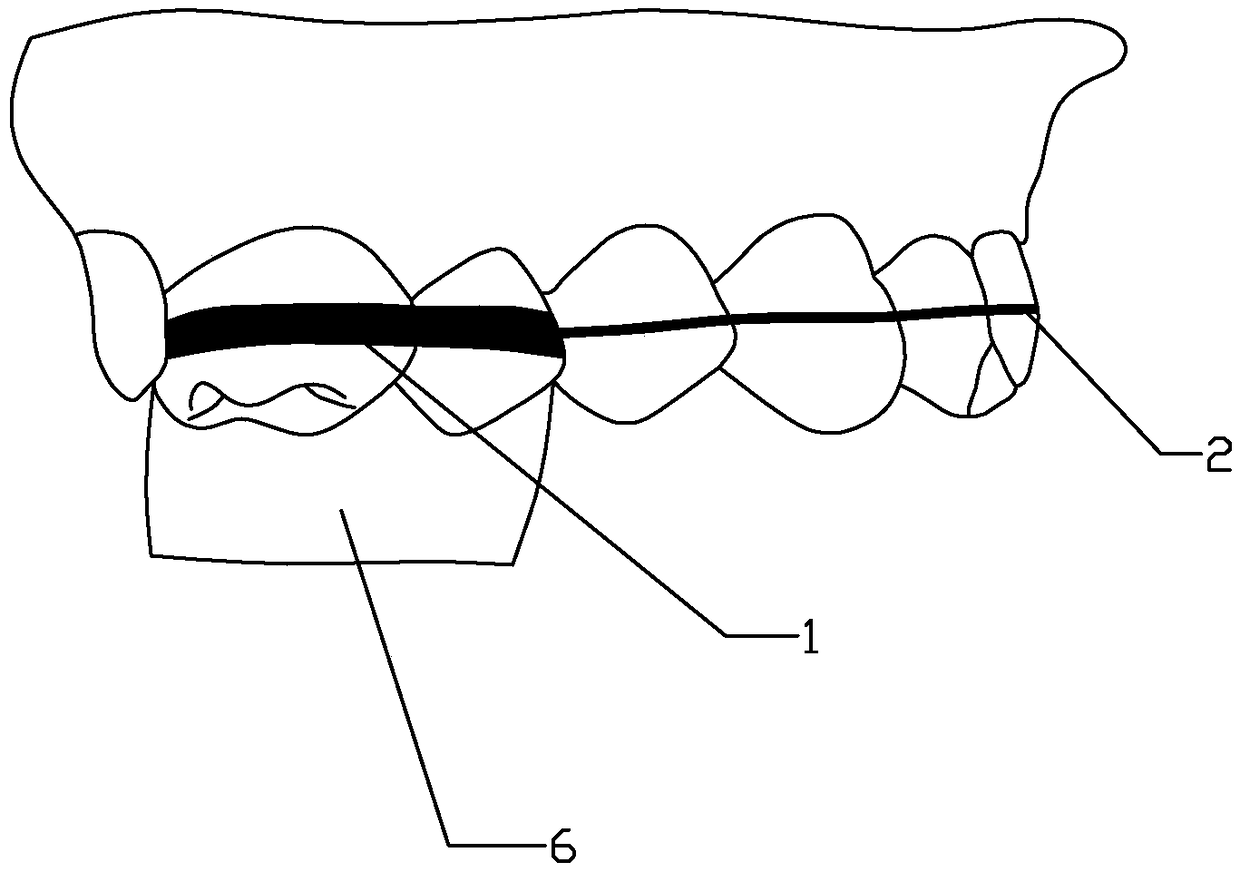

Oral appliance

PendingCN109009502AEven by forceImprove the correction effectOthrodonticsOral applianceUpper Jaw Tooth

Owner:FOSHAN UNIVERSITY +1

Manufacturing method of implantation guide plate

PendingCN114767301AAvoid narcoticsEasy to makeDental implantsComputerised tomographsRetainerSilicon rubber

Owner:仲维广

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap