Axial-flow windwheel

An axial-flow wind and hub technology, which is applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc. It takes away the heat of the outdoor unit and does not consider reducing the separation of the boundary layer, so as to achieve the effects of low rotor weight and rotor production cost, reduced wake strength, low noise and motor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

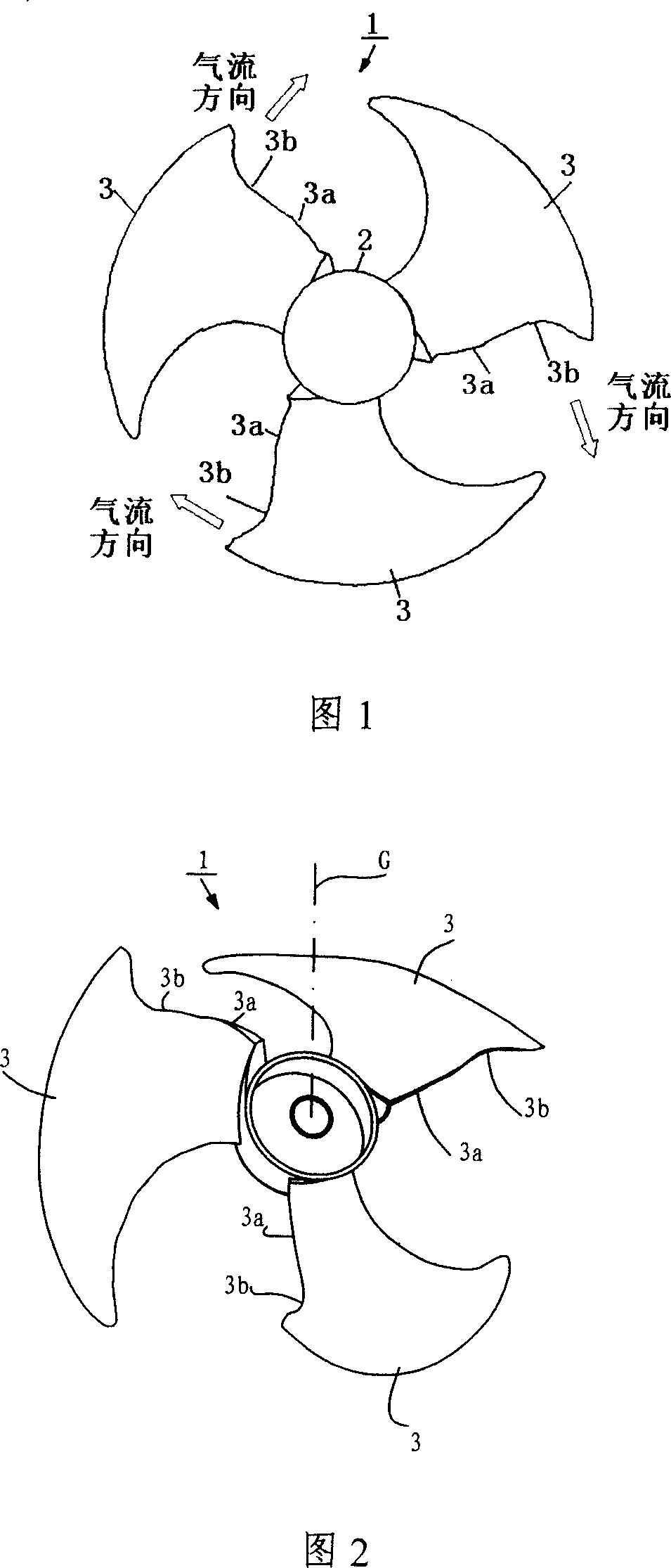

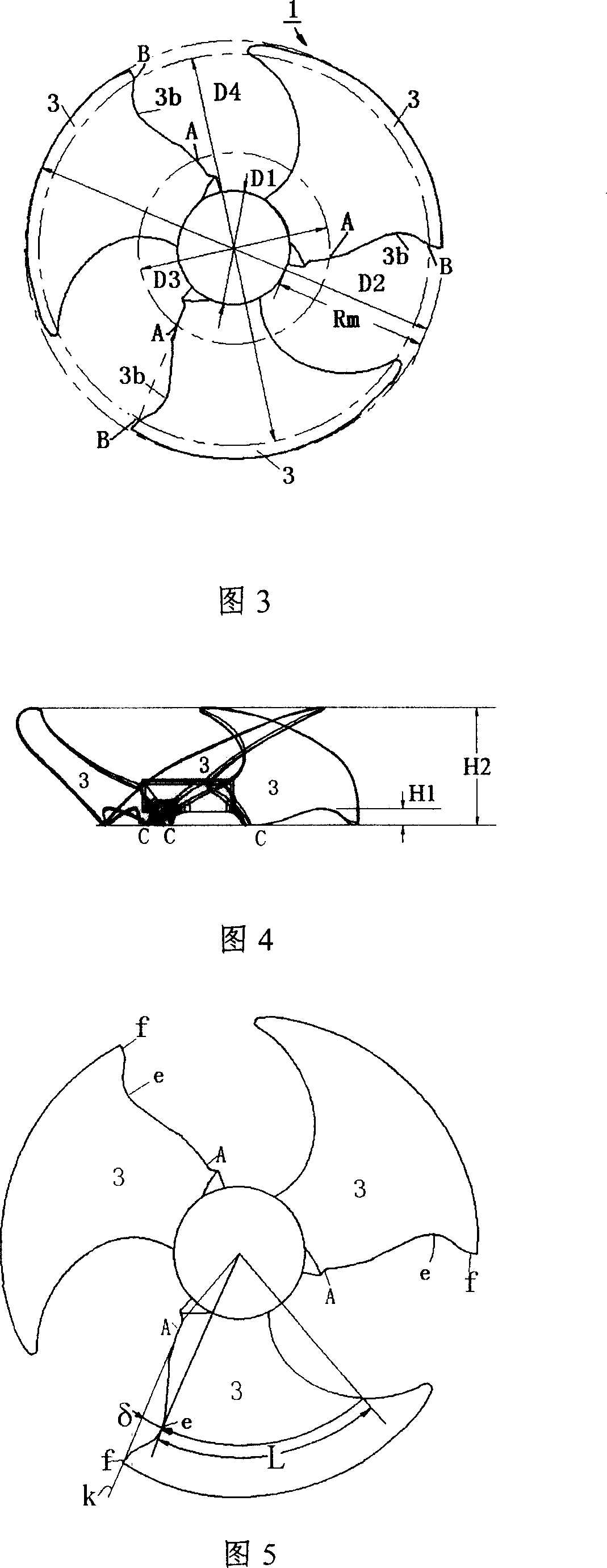

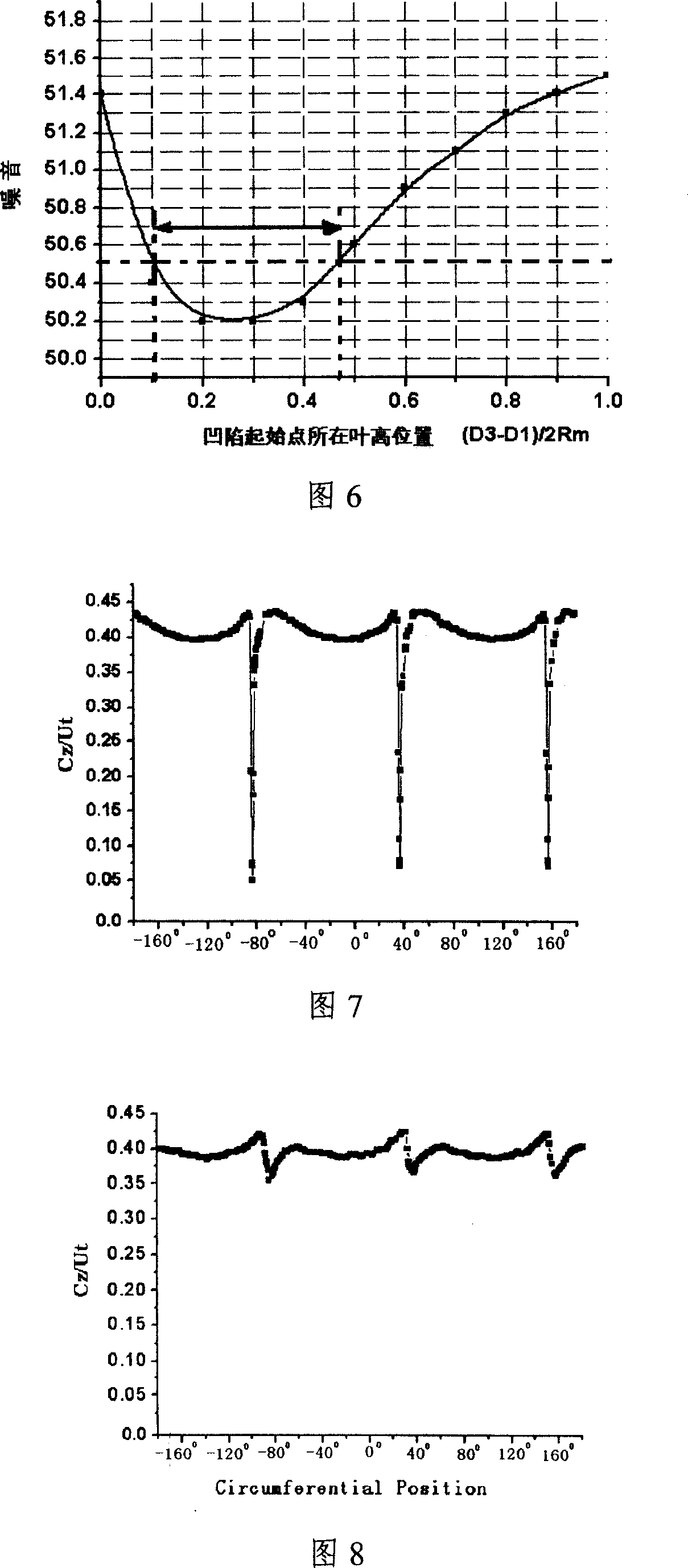

[0025] The present invention will be further described below with reference to the drawings and embodiments.

[0026] In the figure, 1 is the axial flow wheel, 2 is the hub, 3 is the blade, 3a is the downstream edge of the airflow, 3b is the recessed part, D1 is the diameter of the hub, D2 is the outer diameter of the axial flow wheel, and D3 is the blade The diameter of the circumference of the starting position A of the trailing edge of the blade, D4 is the diameter of the circumference of the position B where the trailing edge of the blade ends, Rm is the height of the blade, H1 is the maximum height of the recessed part from the lowest position C of the trailing edge of the blade 3, H2 Is the height of the wind turbine blade calculated from the lowest position C of the trailing edge of the blade 3, δ is the depth of the depression, L is the length of the chord line of the blade, f is the tip trailing edge point, k is the connection line, 11 is the outdoor air-conditioning unit,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap