Automatic rotating machine

An automatic rotating, movable wheel technology, applied in the direction of engines, machines/engines, and mechanisms that generate mechanical power, etc., can solve the problems of limited development space, environmental protection problems and the unsolved greenhouse effect, and natural environment impact of hydropower generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The automatic rotating machine of the present invention can use the kinetic energy generated by the rotation of the gravity rotating metal belt to directly drive the machine or drive the generator to generate the required power or power generation, and then provide cheap and beautiful power to meet people's needs for energy use , and will not increase the burden and pollution of the environment.

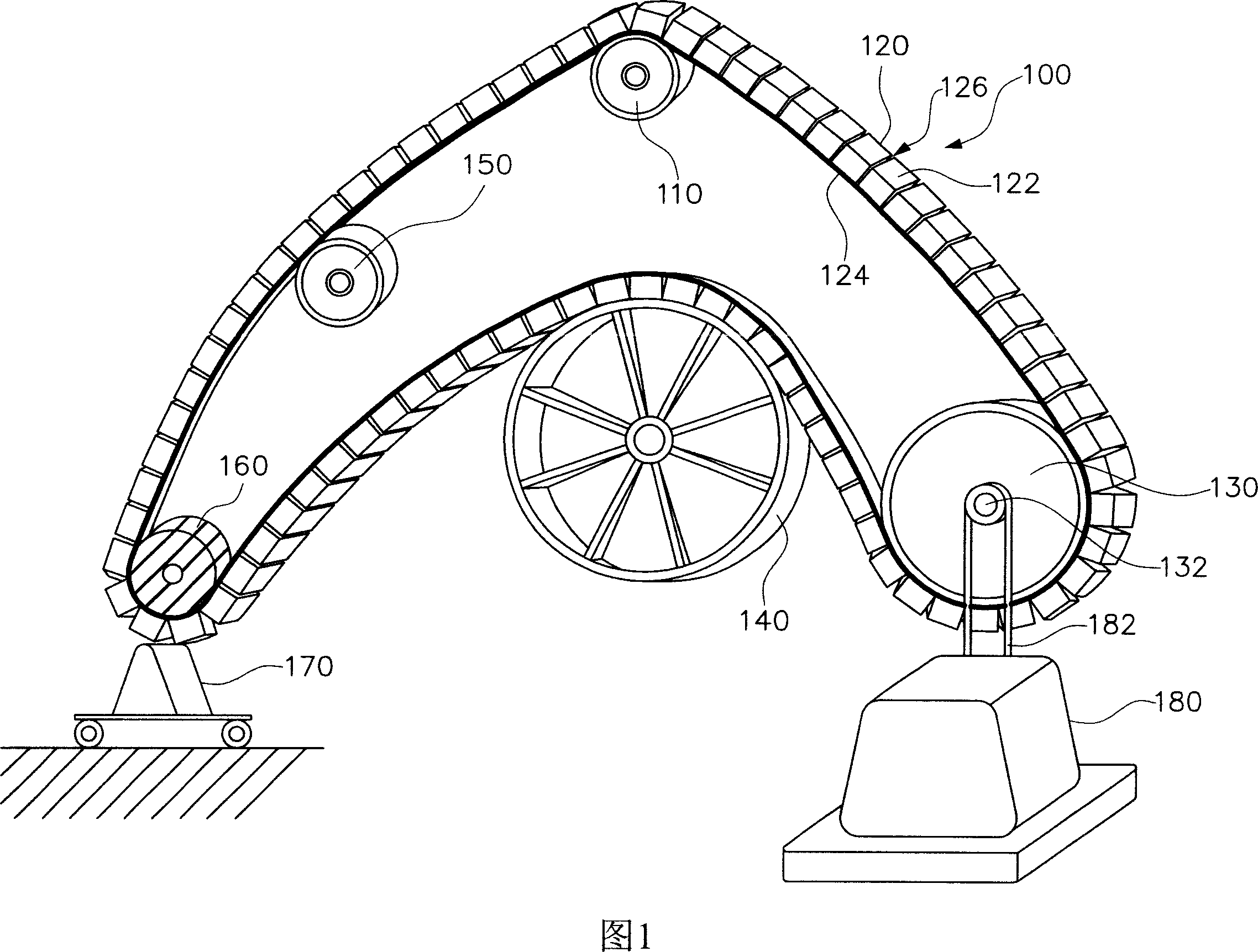

[0031] Referring to FIG. 1 , it shows a schematic diagram of a preferred embodiment of the automatic rotating machine of the present invention. As shown in the figure, the automatic rotating machine 100 includes a main wheel 140 , a first secondary wheel 110 , a second secondary wheel 130 , a weighted movable wheel 160 , a stopper 170 and a gravity rotating metal belt 120 .

[0032] The gravity rotating metal belt 120 surrounds the outer periphery of the first auxiliary wheel 110 , the second auxiliary wheel 130 and the weighted movable wheel 160 , and the main wheel 140 is suppo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap