Vertical cavity surface emitting laser of TO packaging

A technology of vertical cavity surface emission and lasers, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of low chip detection and monitoring efficiency, and achieve the effect of improving detector efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

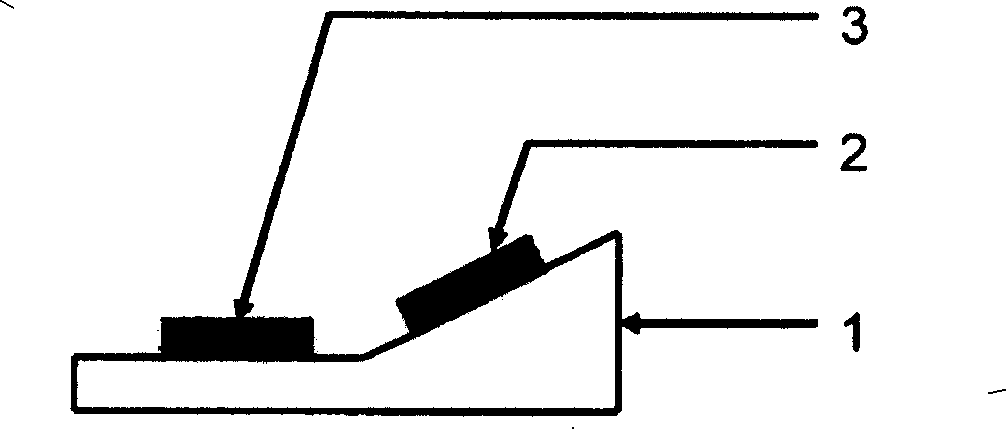

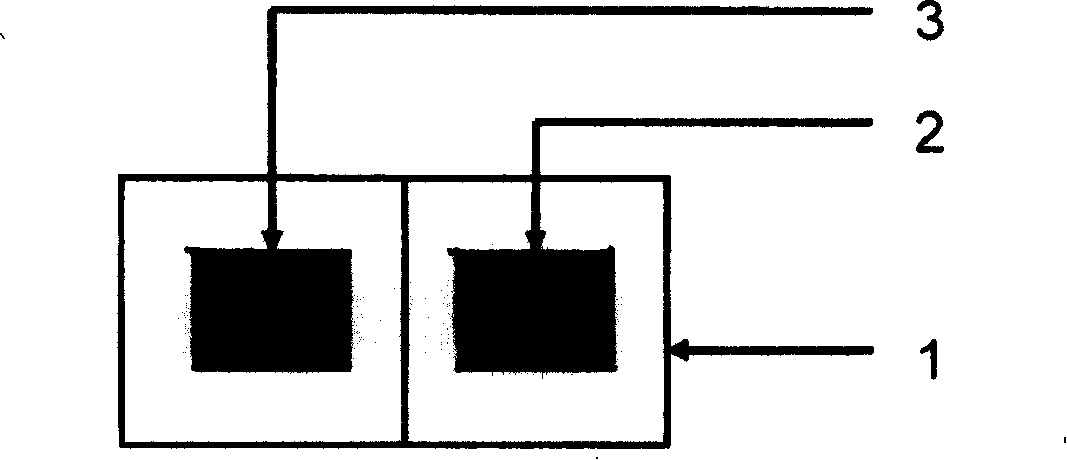

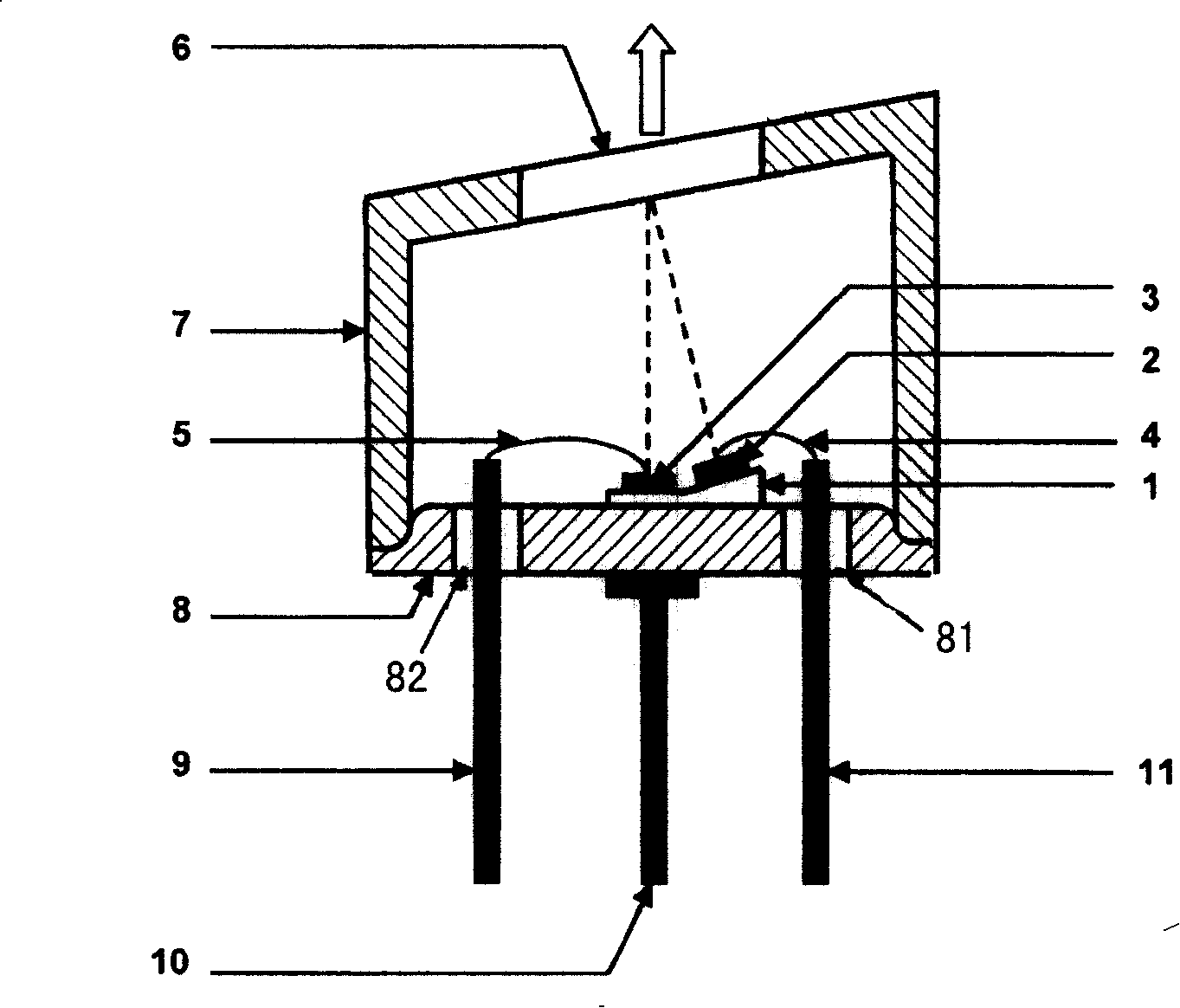

[0026] see figure 1 , figure 2 and image 3 ,Such as image 3 Shown, the vertical cavity surface emitting laser of a kind of TO package of the present invention, comprises:

[0027] A heat sink 1, the heat sink 1 is rectangular, and one end of the heat sink 1 is a slope; the heat sink 1 is made of oxygen-free high-conductivity copper or diamond or valve or silicon carbide or beryllium oxide or aluminum nitride etc. materials with high thermal conductivity and low expansion coefficient; the heat sink 1 prototype is obtained by wire cutting or etching; the upper and lower surfaces of the heat sink 1 are ground and polished; the upper and lower surfaces of the heat sink 1 are plated with gold; The heat sink 1 thus treated has good electrical and thermal conductivity;

[0028] A detector chip 2, the detector chip 2 is pasted on the inclined surface of one end of the heat sink 1 with solder; the effect of fixing the detector chip 2 on the heat sink 1 with solder is that the detec

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap