Plate type solar hollow heat collection strip

A kind of solar energy and flat-panel technology, applied in the direction of solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of complicated process, high production cost, increased difficulty of vacuum process and sealing structure, etc., to simplify the process link and reduce the production cost cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

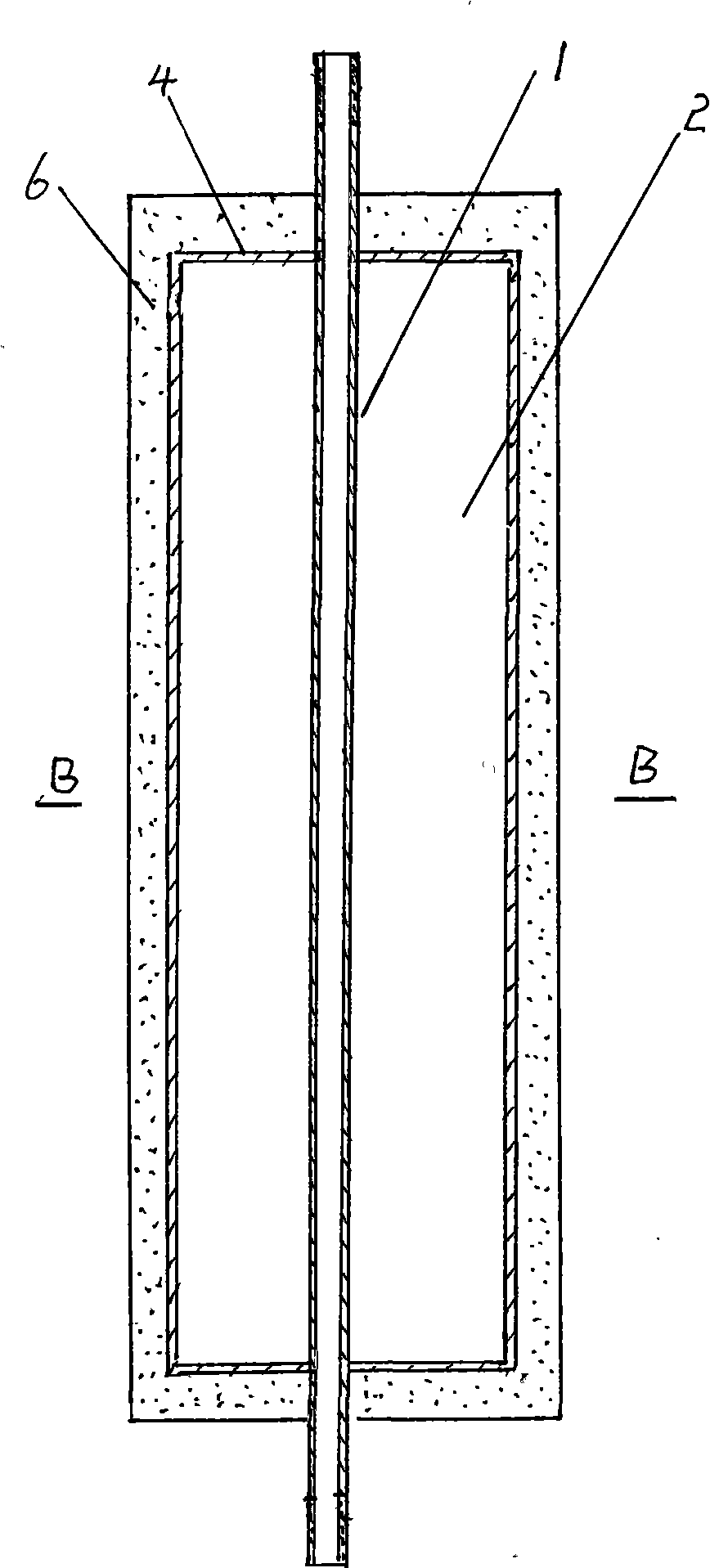

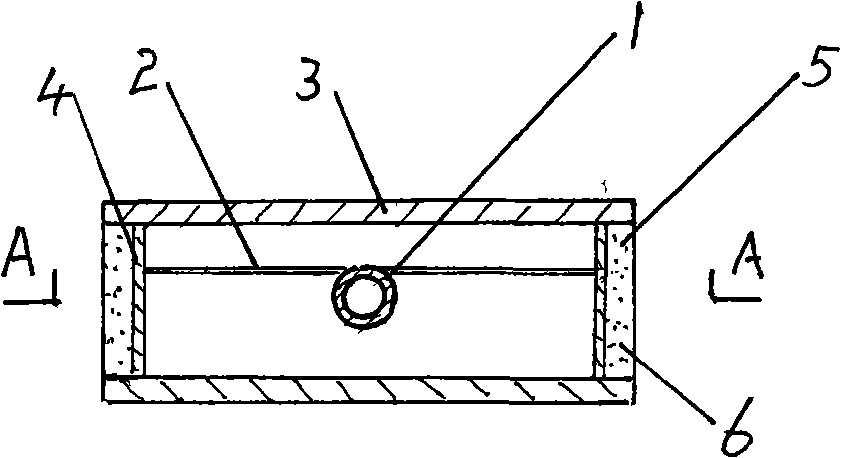

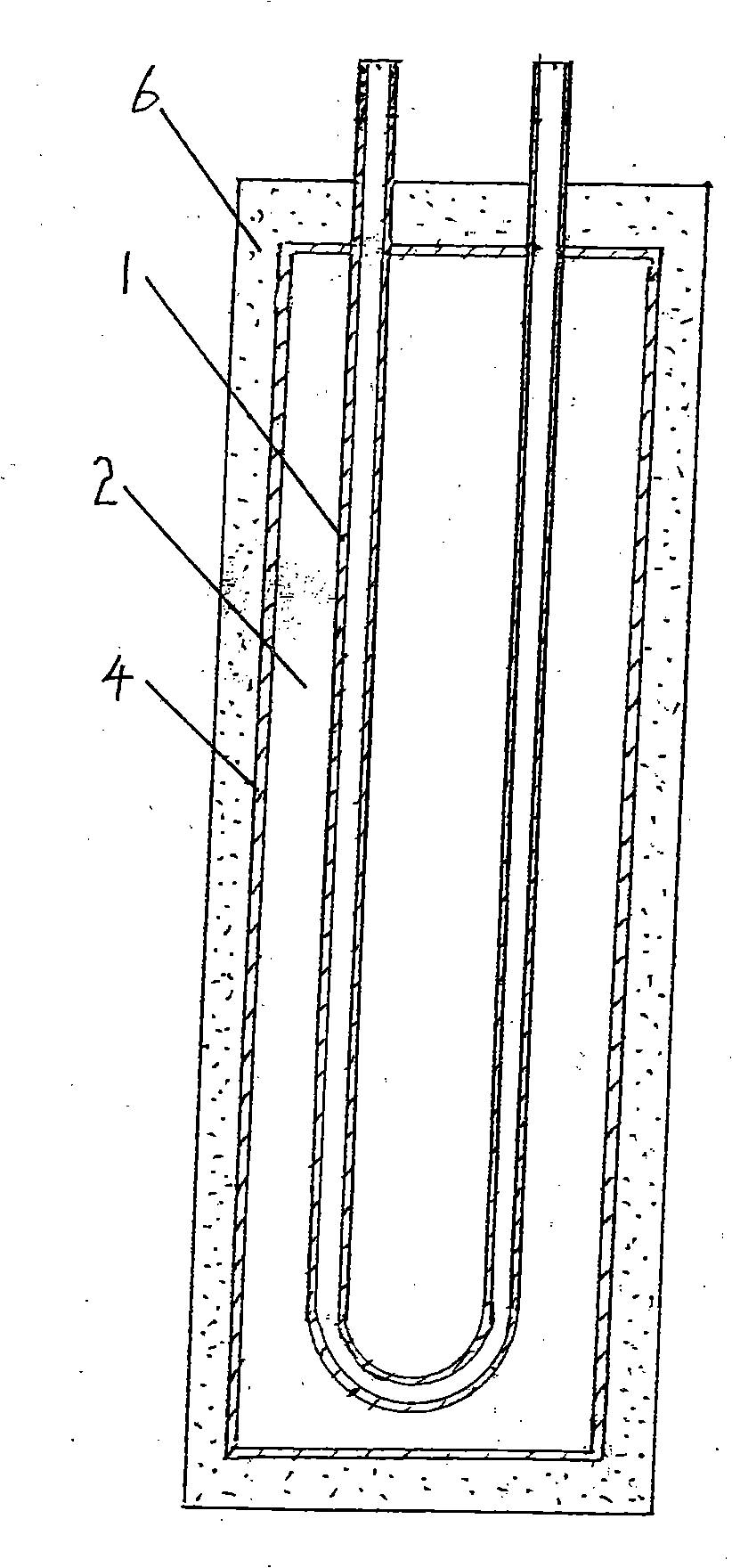

[0013] As shown in Fig. 1, Fig. 2, the present invention is made up of heat collecting tube 1, fin 2 and cover plate 3, it is characterized in that, the panel of cover plate 3 and the back plate are two tempered glass plates; Between the panel and the back plate The cavity is set to be hollow, and inert gas is filled in the hollow cavity to enhance its thermal insulation performance; spacers 4 are arranged around the fins 2 between the panel and the back plate; the spacer 4 is connected with the panel and the back plate A groove 5 is formed between them; a heat insulating layer 6 is filled on the groove 5 around the periphery of the heat collecting strip, and the material of the heat insulating layer is polyurethane; connecting threads 7 are provided on both ends of the heat collecting tube 1 . According to the Fig. 1 structure of the heat collecting tube, the present invention is connected with the solar energy, and the two ends of the heat collecting tube can be respectively co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap