Fine grinding non-corrodible steel high temperature and high pressure resistant hollow floating ball

A hollow floating ball and fine grinding technology, which is applied in steam traps, piping systems, mechanical equipment, etc., can solve the problems of stainless steel hollow floating balls, such as insufficient roundness, high temperature and high pressure resistance, etc., to improve service life and prevent deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

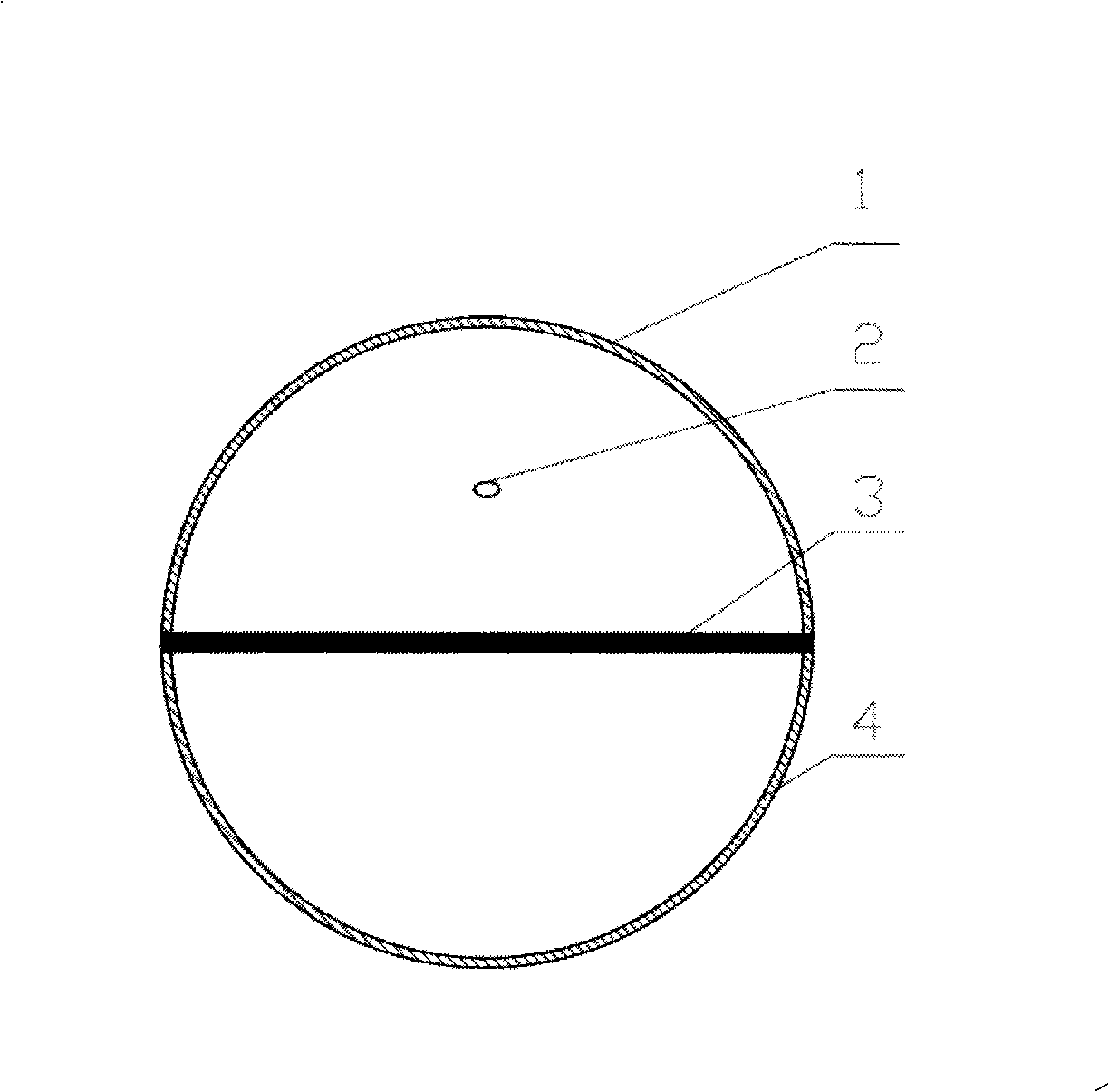

[0023] Such as figure 1 As shown, the finely ground stainless steel pressure-resistant hollow float is mainly composed of an upper hemisphere (1), a vent hole (2), a centerline weld (3) and a lower hemisphere (4). Firstly, design a semi-spherical drawing die, and stretch the stainless steel plate into two semi-spherical semi-sphericals with equal wall thickness through a numerical control hydraulic stretching machine, namely the upper hemisphere (1) and the lower hemisphere (4); trim the edges according to the design parameters , a 1.5mm vent hole (2) is drilled on the top of the upper hemisphere (1), so that the hollow ball maintains the balance of internal and external pressure during welding; the upper hemisphere (1) and the lower hemisphere (4) are connected in a triangular shape by argon shield welding The welding is fixed without leaving a gap; then

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap