Splitlevel heat resistance socket

A technology of heat protection and sockets, which is applied in the direction of electrical components, coupling devices, circuits, etc., can solve the problems of increasing the volume of sockets and restrictions on application occasions, and achieve the effects of improving positioning accuracy, improving electrical insulation performance, and enhancing heat insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

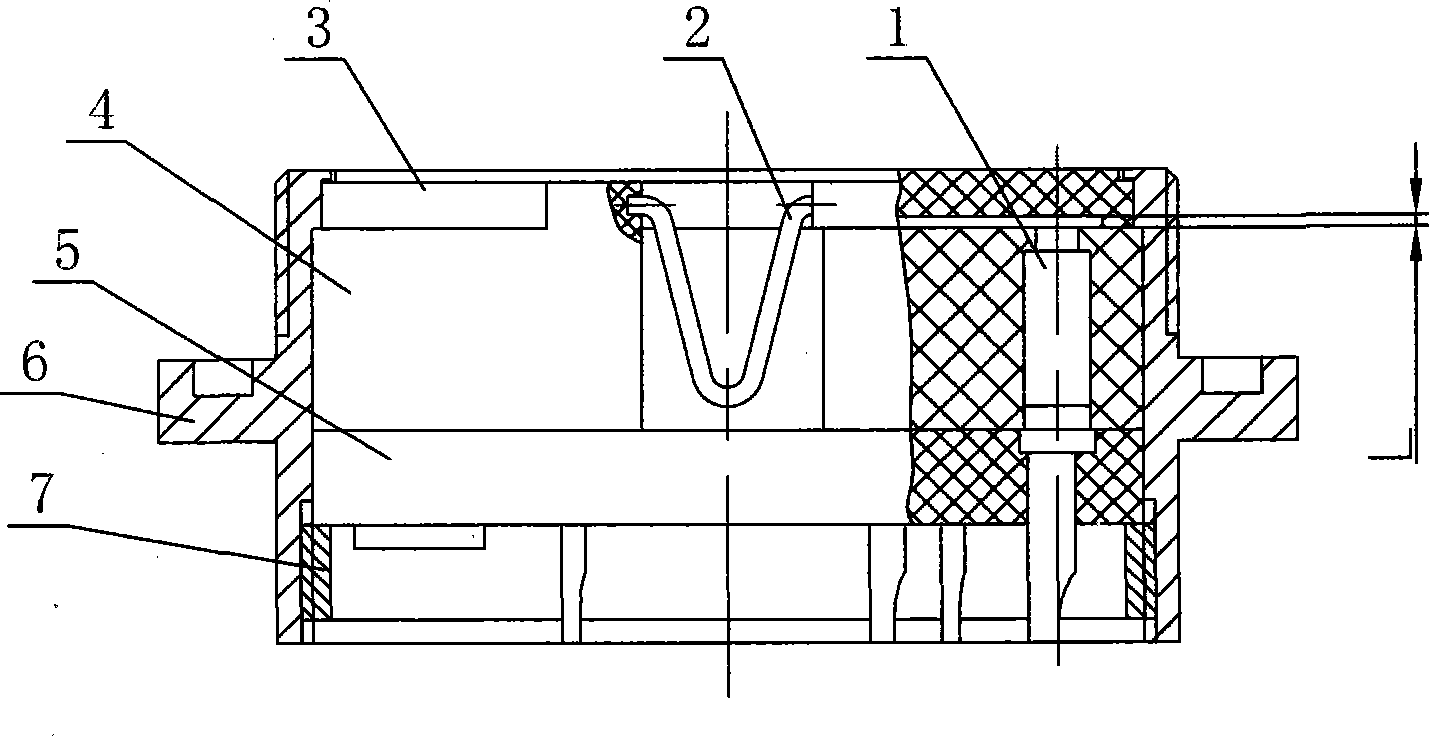

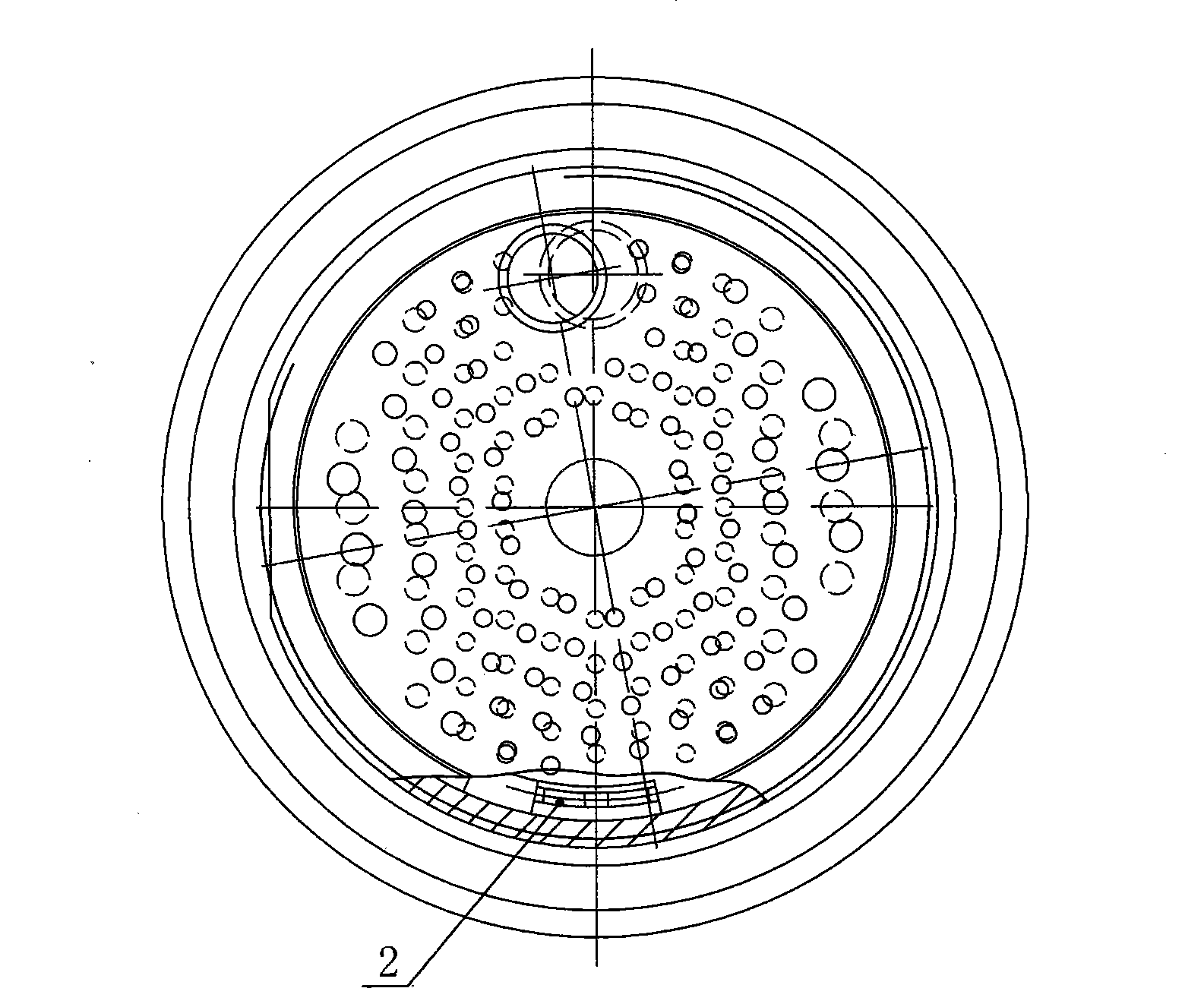

[0009] The embodiment of the split-level heat-proof socket of the present invention will be further described in detail with reference to the accompanying drawings: its structure consists of a jack contact 1, a special-shaped spring 2, a heat shield 3, an upper insulator 4, and a lower insulator 5 , The shell 6 and the pressure ring 7 are composed. The jack contact 1 is kept in the correct position through the alignment of the upper insulator 4 and the lower insulator 5, and is fixed in the housing 6 by the pressure ring 7 to form a reliable contact fixing structure. The heat shield 3 can be placed on the upper insulator 4 and the housing 6 The angle of rotation in the space provided therebetween is limited by the upper insulator 4 . On the heat insulation board 3 and the corresponding position of the upper insulator 4, there are several round holes of different sizes. The size and arrangement of the holes on the heat insulation board 3 are the same as those of the insulator 4.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap