Oil-gas separating device of cylinder cap

A technology of cylinder head cover and separation device, which is applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of high cost, complex production process, engine oil leakage, etc., to improve performance, reduce environmental pollution, The effect of improving emission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

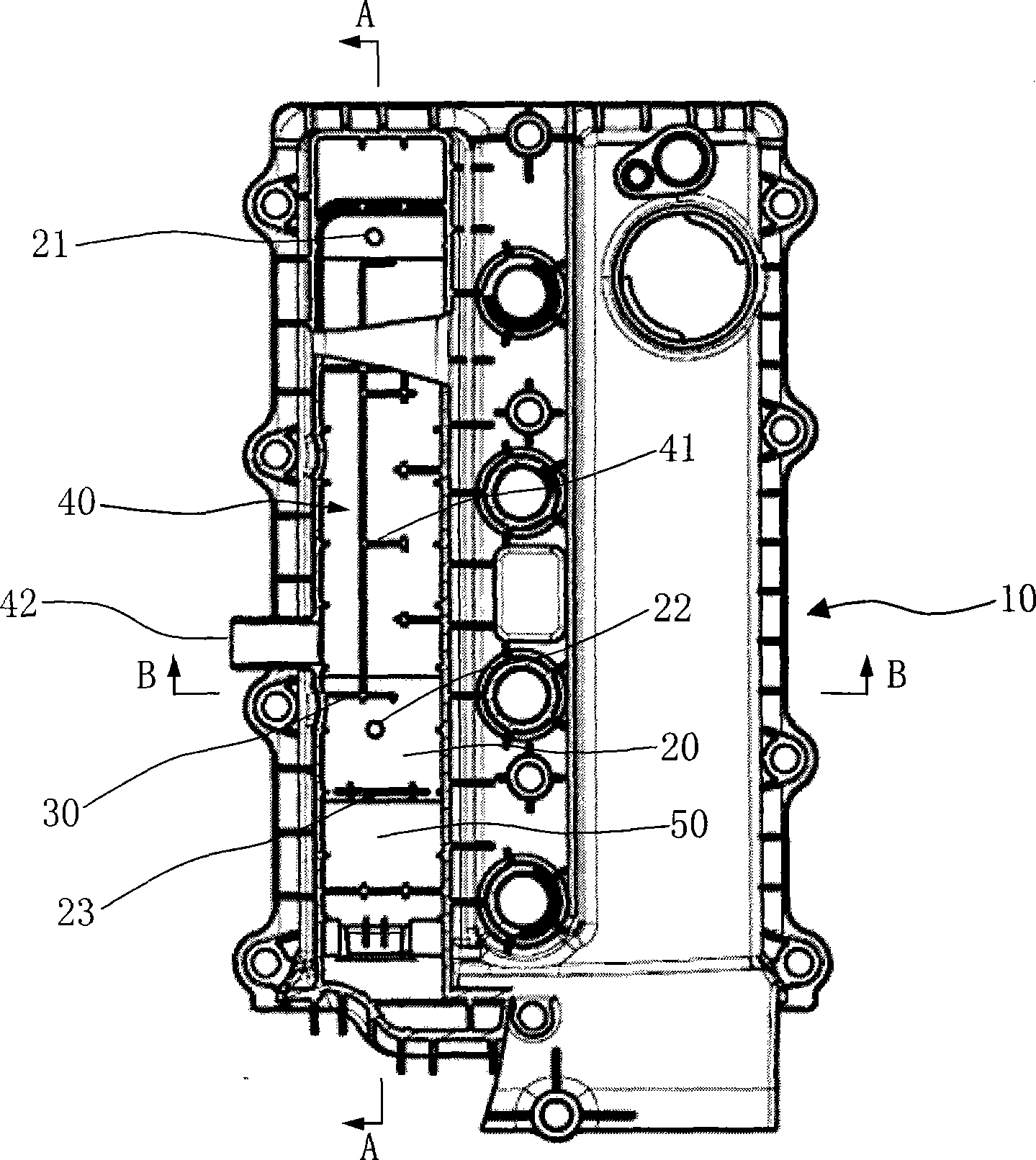

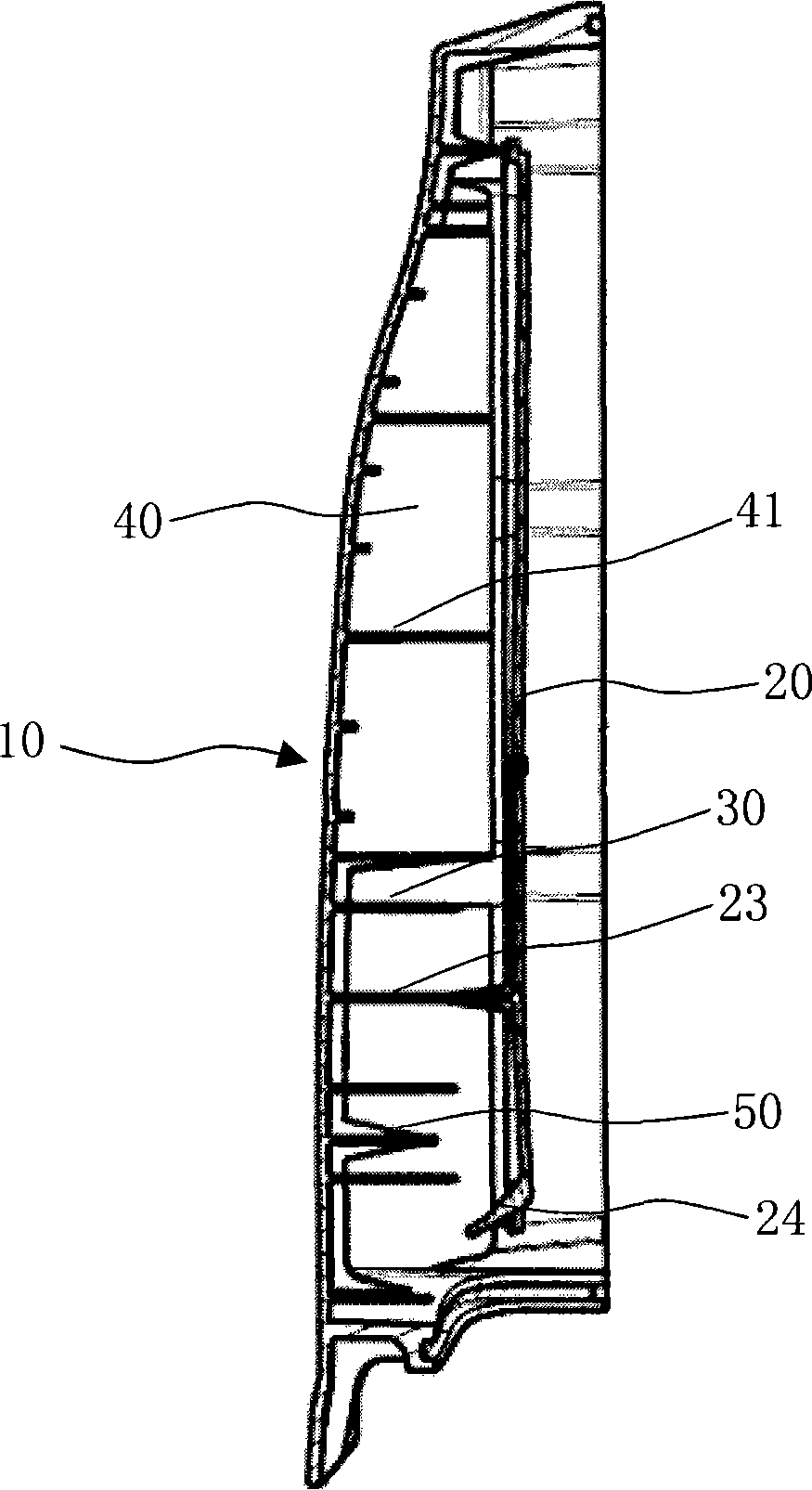

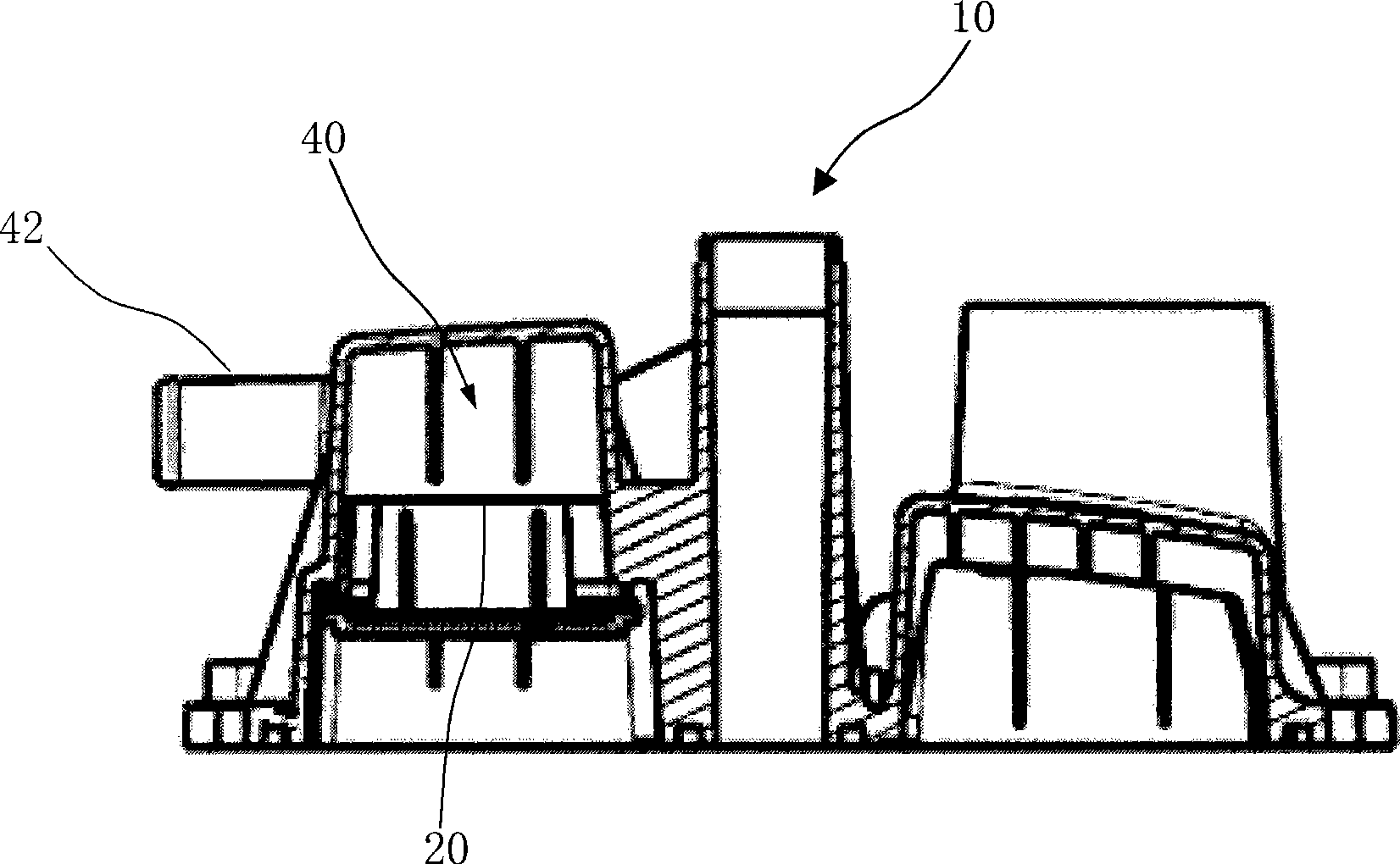

[0010] Such as figure 1 As shown, a cylinder head cover oil-gas separation device is provided with a bottom plate 20 on the lower side of the cylinder head cover 10, a top-to-bottom partition plate 30 is provided between the cylinder head cover 10 and the bottom plate 20, the cylinder cover 10, the bottom plate A cavity 40 is formed between 20 and the partition plate 30 for the circuitous flow of oil and gas. The inlet of the cavity 40 is arranged inside the cylinder cover 10, the outlet is arranged on the cylinder cover 10, and the cavity 40 is arranged along the front cavity of the oil flow direction. There is an oil-gas separation mechanism, the rear cavity is set as a passage, and the bottom plate 20 is provided with a first oil return hole 21.

[0011] When working, the oil and gas flow in from the inlet of the cavity 40, and are first processed by the oil and gas separation mechanism, and then the gas flows back to the passage behind the cavity 40. Since there are no obstacles

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap