Sealing structure of duplex cylinder compressor lower bearing and lower silencer

A technology of sealing structure and muffler, applied in the direction of machine/engine, mechanical equipment, liquid fuel engine, etc., can solve the problems of reducing noise reduction effect, leakage, affecting sealing effect, etc., to improve the working environment, improve noise reduction performance, The effect of prolonging the service life

Inactive Publication Date: 2009-07-01

LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This patented design provides an improved seal system by adding a special material called a bell cushion or metal ring between two parts: one has a smaller inner diameter than another component's outer size while still being able to work properly together well without leaks during operation. Additionally, there can be a separate space inside this area which helps reduce vibrations caused when these components move back and forth smoothly through different directions. Overall, it enhances the overall function of the compression machine.

Problems solved by technology

This patent describes different technical problem addressed in the design process described above relates to improving the quality of the oil mist contained within the airflow passing over the turbine housing (muffling machine). Existing solutions involve adding extra elements such as bushings or filters to prevent these leaks from happening, increasing manufacturing costs associated with the use of higher strength materials. Additionally, conventional methods involving installing multiple layers of dirt isolators may result in increased leakages caused by imperfections in the material itself.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

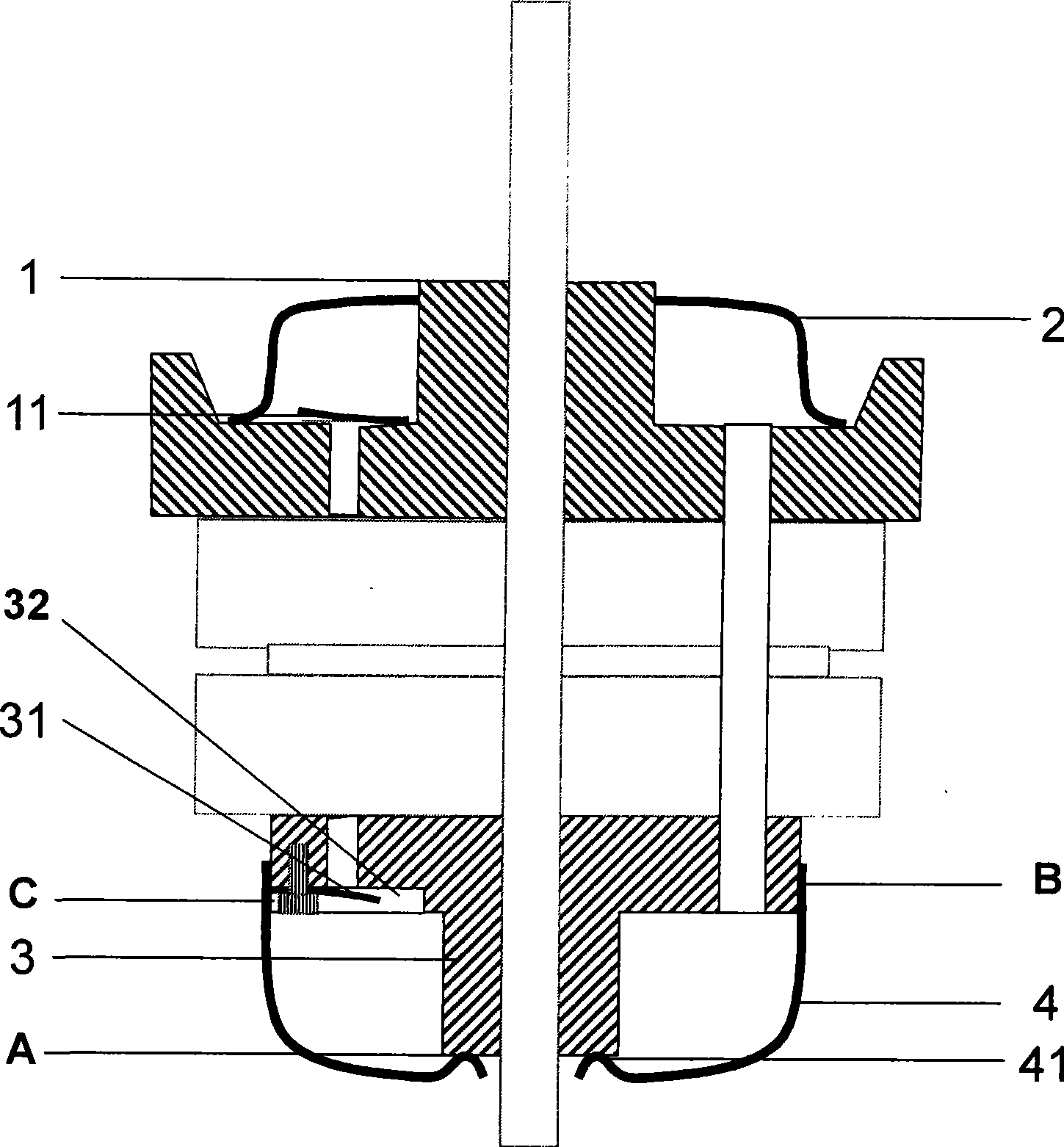

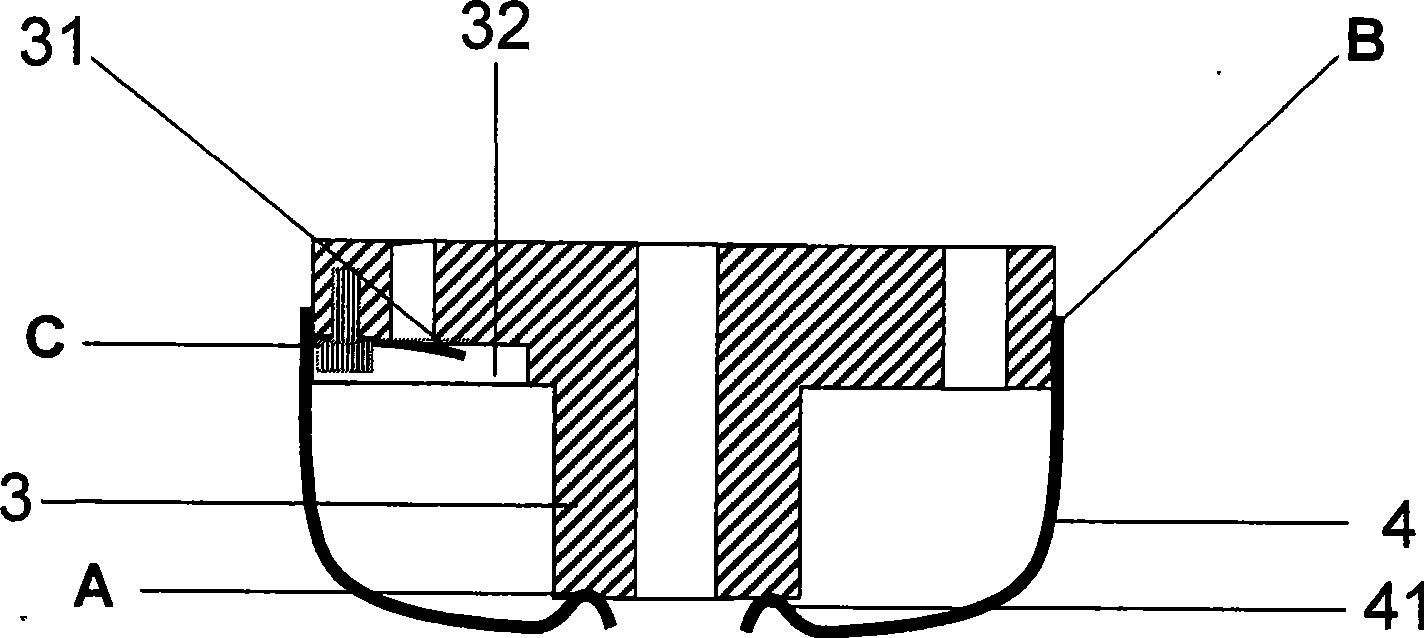

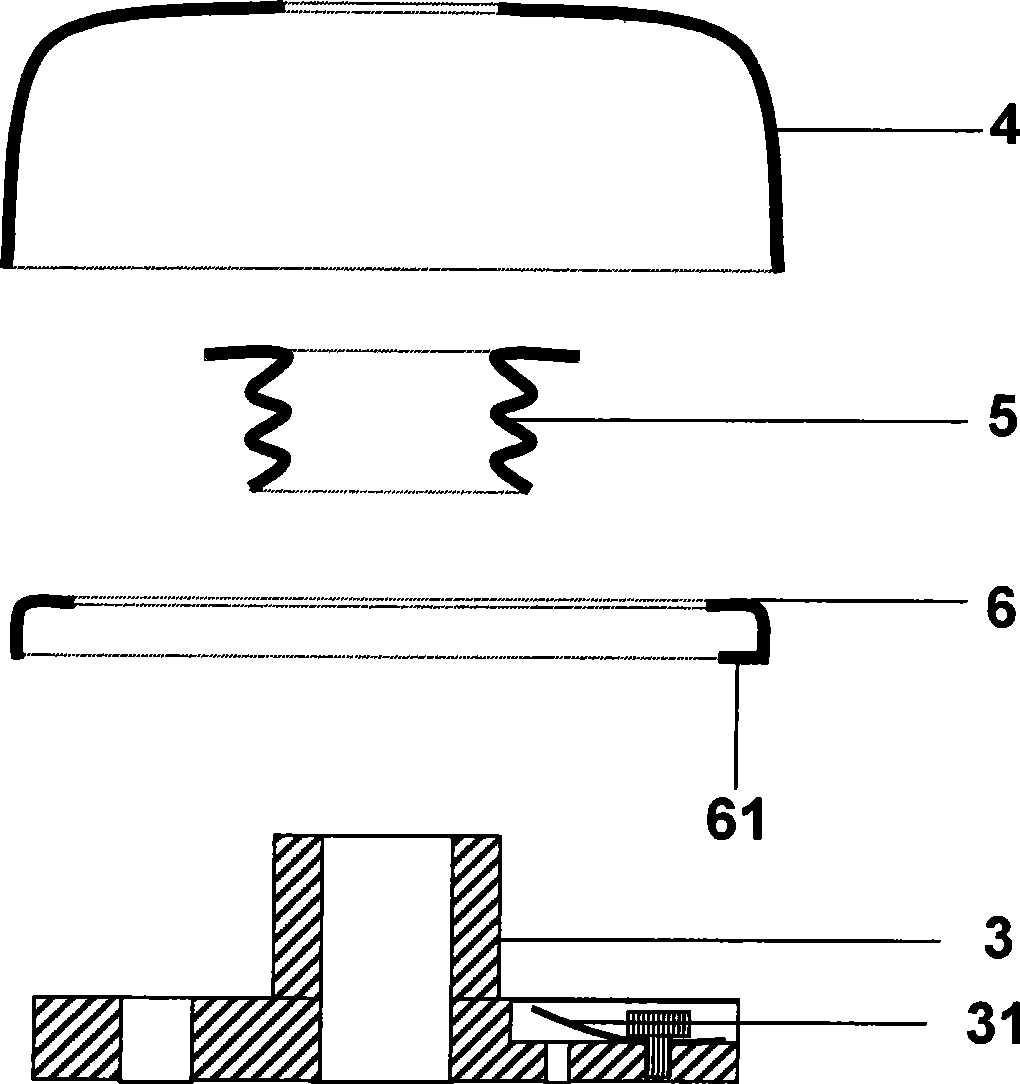

The present invention provides a sealing structure of duplex cylinder compressor lower bearing and a lower sound eliminator, which includes a lower bearing and a lower sound eliminator; characterized in that a corrugated pipe and a ferrule are set between the lower bearing and the lower sound eliminator; the corrugated pipe is set on the location where the lower sound eliminator contacts with the lower bearing non-working surface small end; lateral wall of the ferrule is provided with a convex slice, wherein the ferrule is set on the location where the lower sound eliminator contacts with the lower bearing non-working surface big end and the convex slice presses the depressed part of the lower valve sheet where to mount the screw hole; leakage between the lower bearing and the lower sound eliminator can be effectively overcome; denoise performance of the sound eliminator and work efficiency of the compressor can be enhanced; working environment of the compressor can be improved; and service life of the compressor can be prolonged.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap