Ink jet pad printing machine and method for ink jet pad printing

A technology for pad printing machines and inkjet printing devices, which is applied to printing machines, transfer printing, rotary printing machines, etc., which can solve problems such as inconvenient storage and search, difficulty in pad printing of patterns, large pattern deformation, etc., and achieve preservation and Find the effect that is convenient, easy to modify, and simple in steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0054] (Example 1, inkjet pad printer)

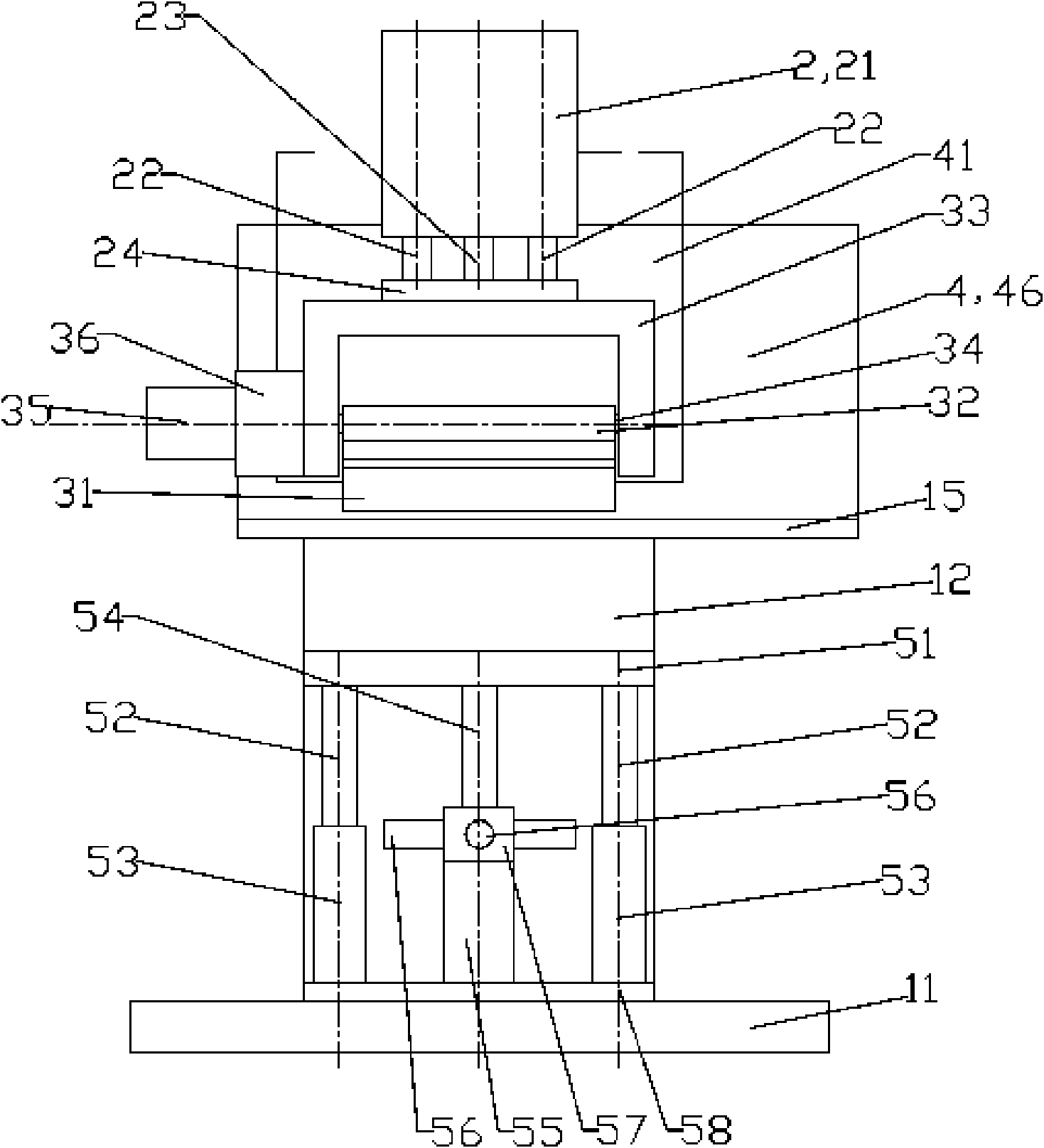

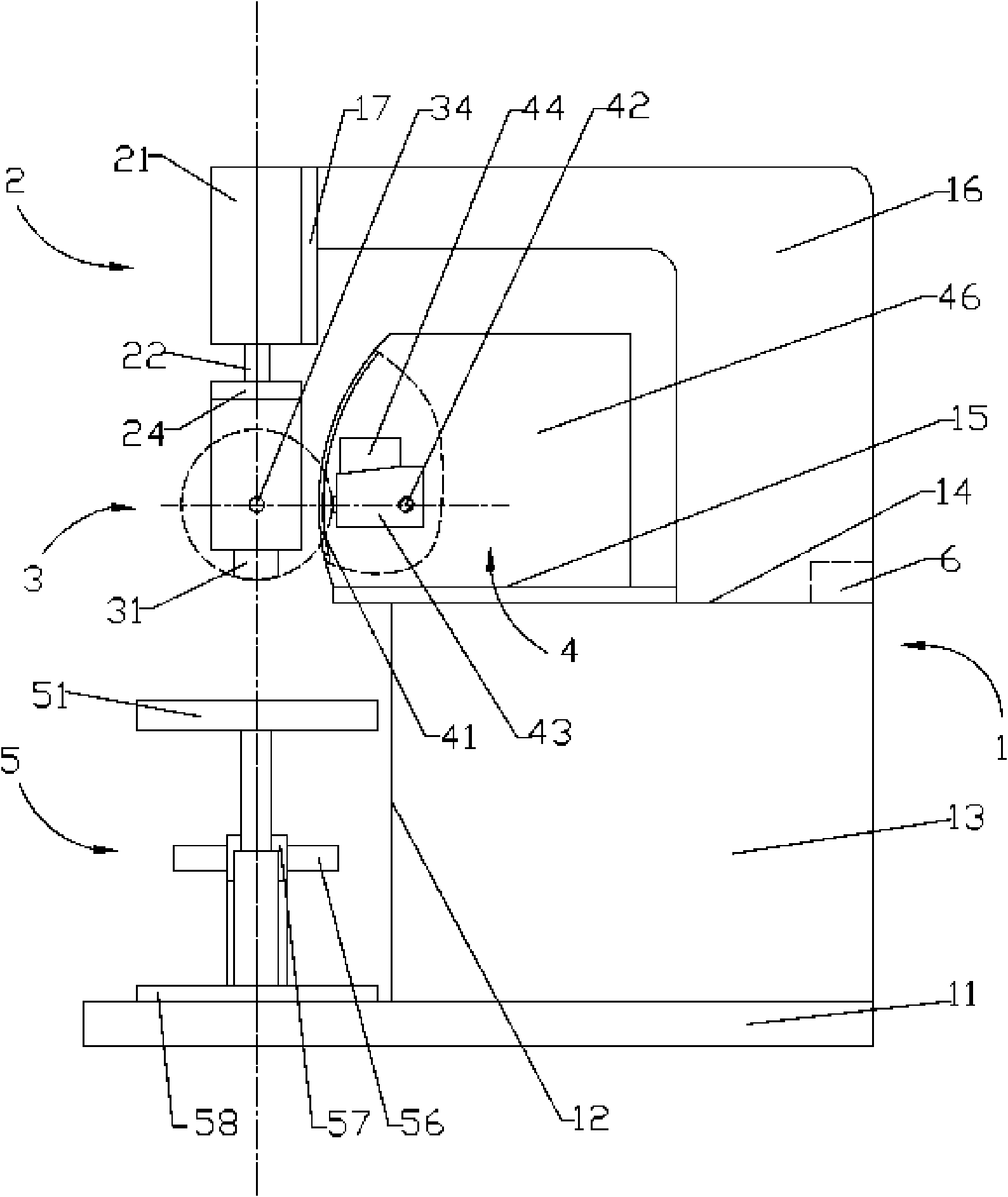

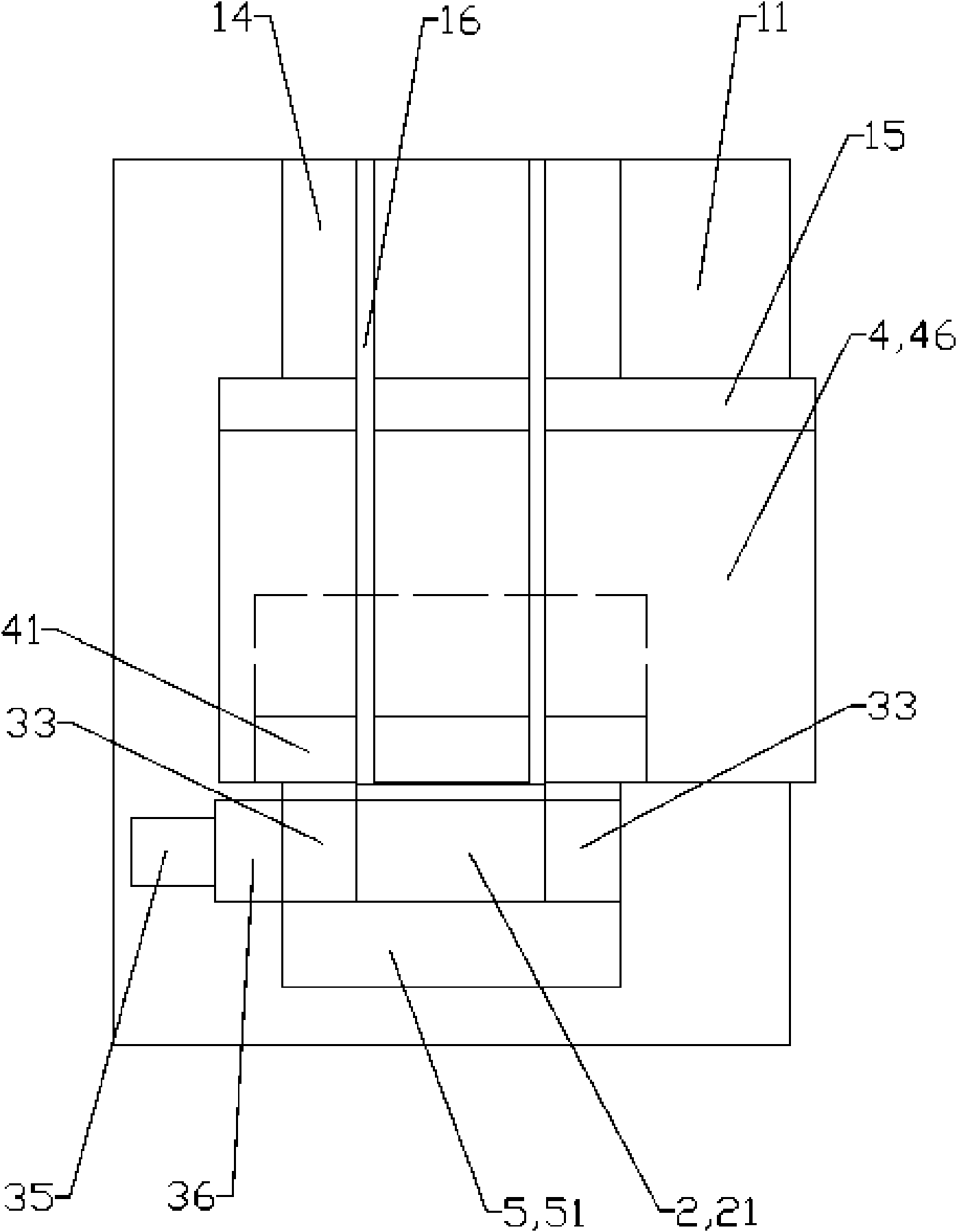

[0055] see Figure 1 to Figure 3 , The inkjet pad printer in the present invention includes a frame 1, a linear moving mechanism 2, an imaging moving part 3, an inkjet printing device 4, a workpiece placement part 5 and a system controller 6.

[0056] See you still Figure 1 to Figure 3 The frame 1 includes a base 11, a front side plate 12, left and right side plates 13, an upper side plate 14, a fixing seat 15, a supporting plate 16 and a cylinder fixing plate 17. Two left and right side plates 13 are welded on the base 11 in parallel and symmetrically, And located above the base 11. The front side plate 12 is welded to two left and right side plates 13 and is located in front of the left and right side plates 13. The upper side plate 14 is welded to the two left and right side plates 13 and is located above the left and right side plates 13. The two left and right side plates 13, the front side plate 12 and the upper side plate 14 are fixedly

Example Embodiment

[0063] (Example 2. Method of inkjet pad printing using inkjet pad printer)

[0064] see Figure 4 In the inkjet pad printing method of this embodiment, the inkjet pad printing system used includes a computer, drawing software set in the hard disk of the computer, and special software for inkjet pad printers, and also includes the inkjet pad printing system described in Example 1. Inkjet printing machine. The inkjet pad printing method of this embodiment includes the following steps:

[0065] ① Use the drawing software in the computer to draw the pattern that needs to be printed and save it to complete the pattern making.

[0066] ②Connect the system controller 6 of the present invention to the computer, put the ink cartridge 44 into the carriage structure 43 of the inkjet printing device 4. According to the height of the workpiece, turn the rotating handle 56 of the workpiece placing part 5 to make the worktable 51 stops at an appropriate position, and places the workpiece in an appr

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap