Guide sleeve removing device in die

A guide sleeve and mold technology, applied in the field of stamping molds, can solve the problems of difficult to remove guide sleeves, guide sleeves falling into, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Hereinafter, the present invention will be described in detail with reference to the drawings.

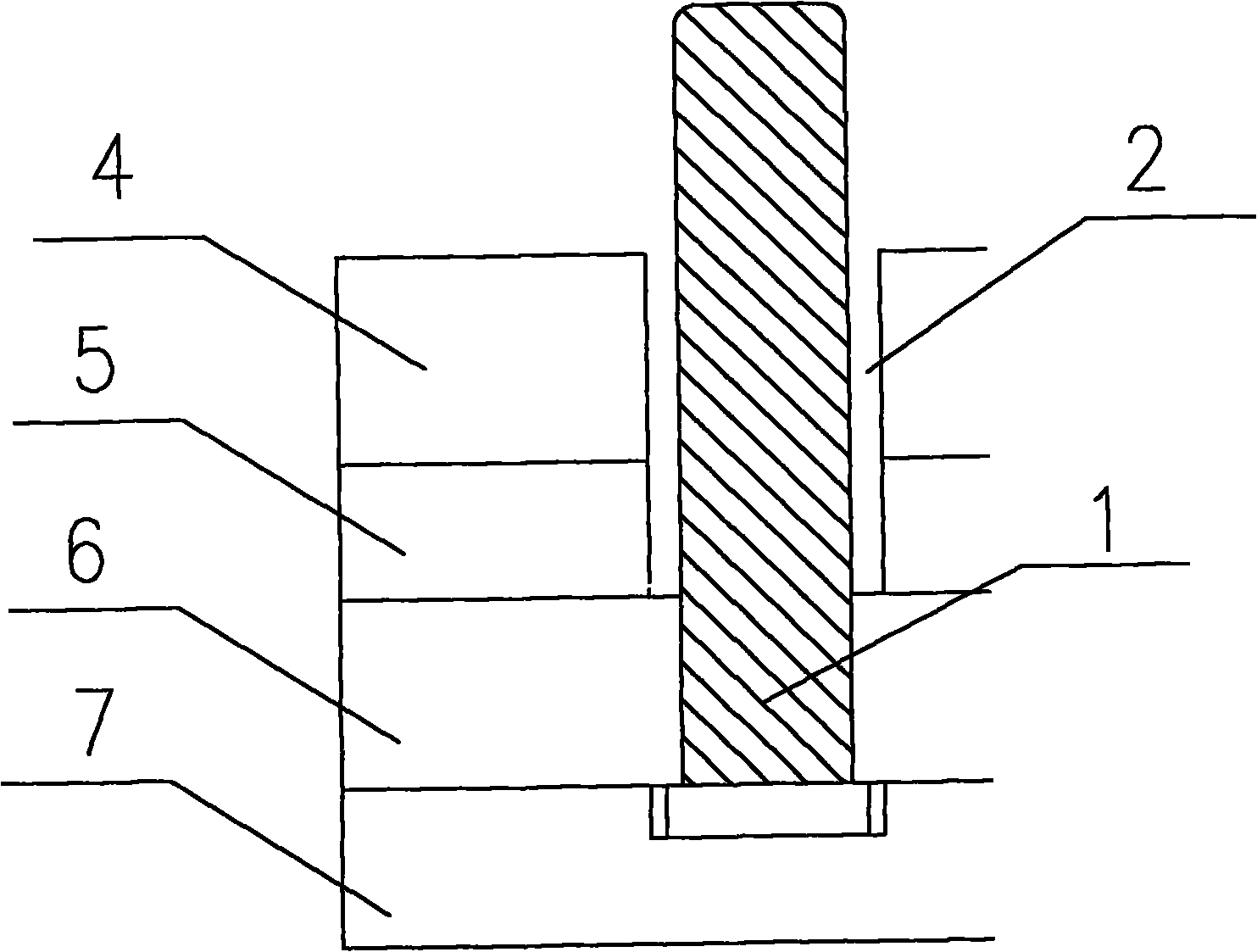

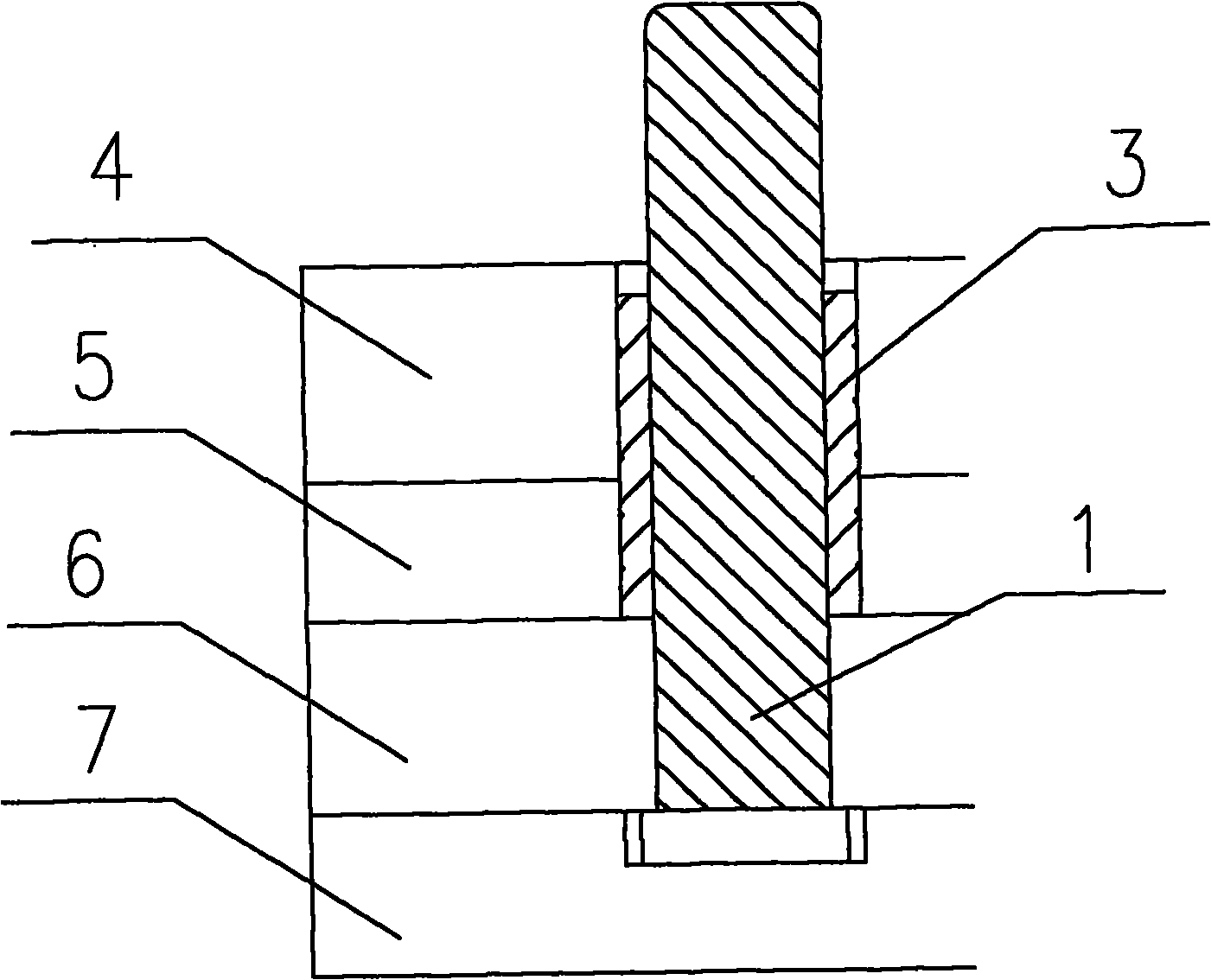

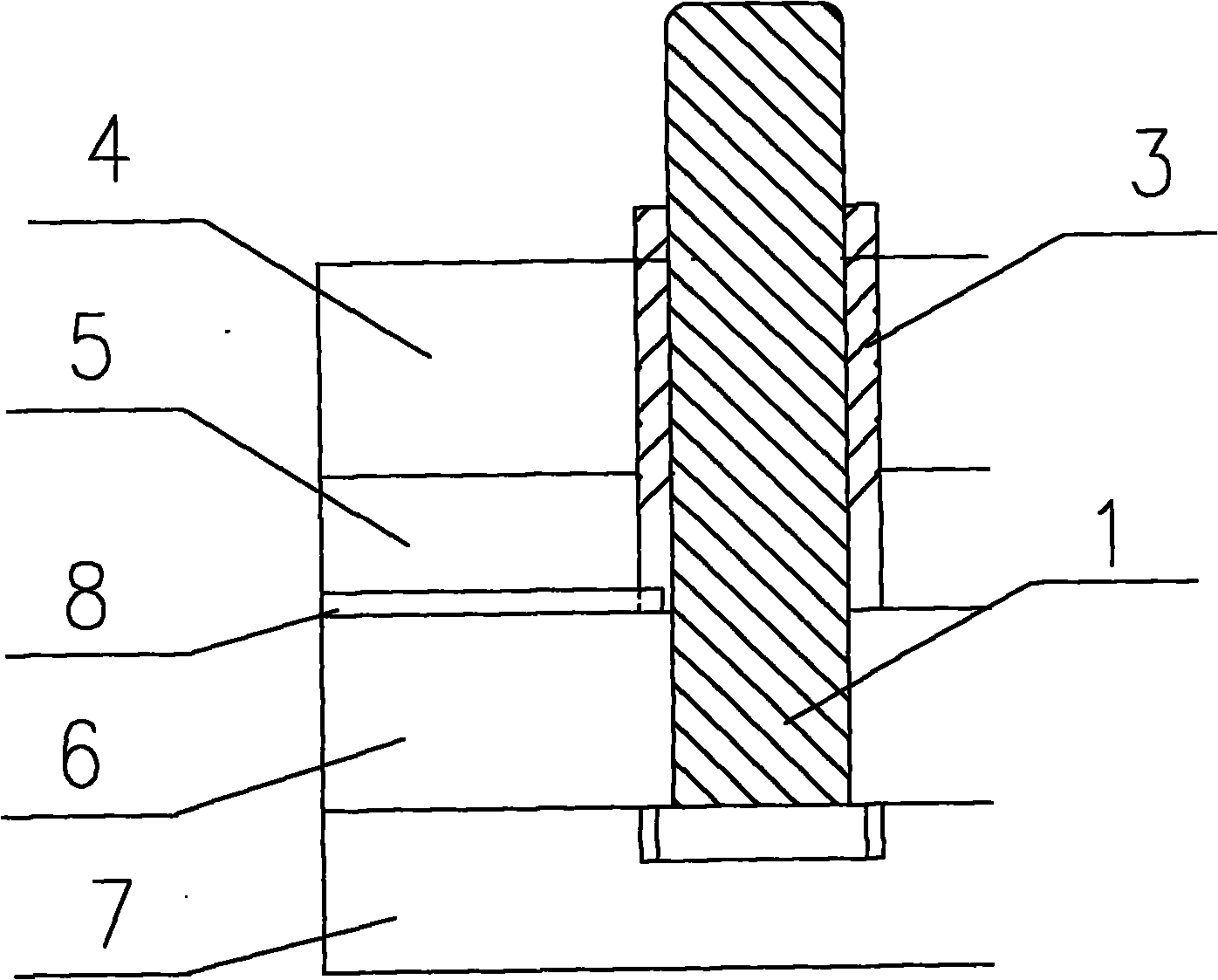

[0013] Such as figure 1 Shown is a schematic structural diagram of a mold without a guide bush installed in the prior art. It can be seen that the guide column 1 is fixed in the lower punch fixing plate 6 and the punch pad 7, and above the guide column 1, there are a stripping back plate 5 and a stripping plate 4, and a stripping back plate 5 and a stripping plate 4 There is an annular hole 2 at a position corresponding to the guide post 1. The annular hole 2 is used to fix the guide sleeve 3 by potting glue. Before the potting preparation, we install the template, and the guide post is also installed in the template, and the template and the guide post are locked tightly. At this time, try to match The gap between the guide post 1 and the guide sleeve 3. At this time, the guide sleeve 3 is relatively loose in the annular hole 2 in the template. Place the guide sleeve 3 in the an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap