Monitoring walking drilling equipment

A drilling equipment and monitoring technology, which is applied in the field of monitoring walking drilling equipment, can solve the problems of high price, labor-intensive shifting, and labor efficiency reduction, and achieve the effects of convenient operation, time-saving and labor-saving operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiment of the monitoring walking drilling equipment of the present invention will be described in detail below in conjunction with the accompanying drawings.

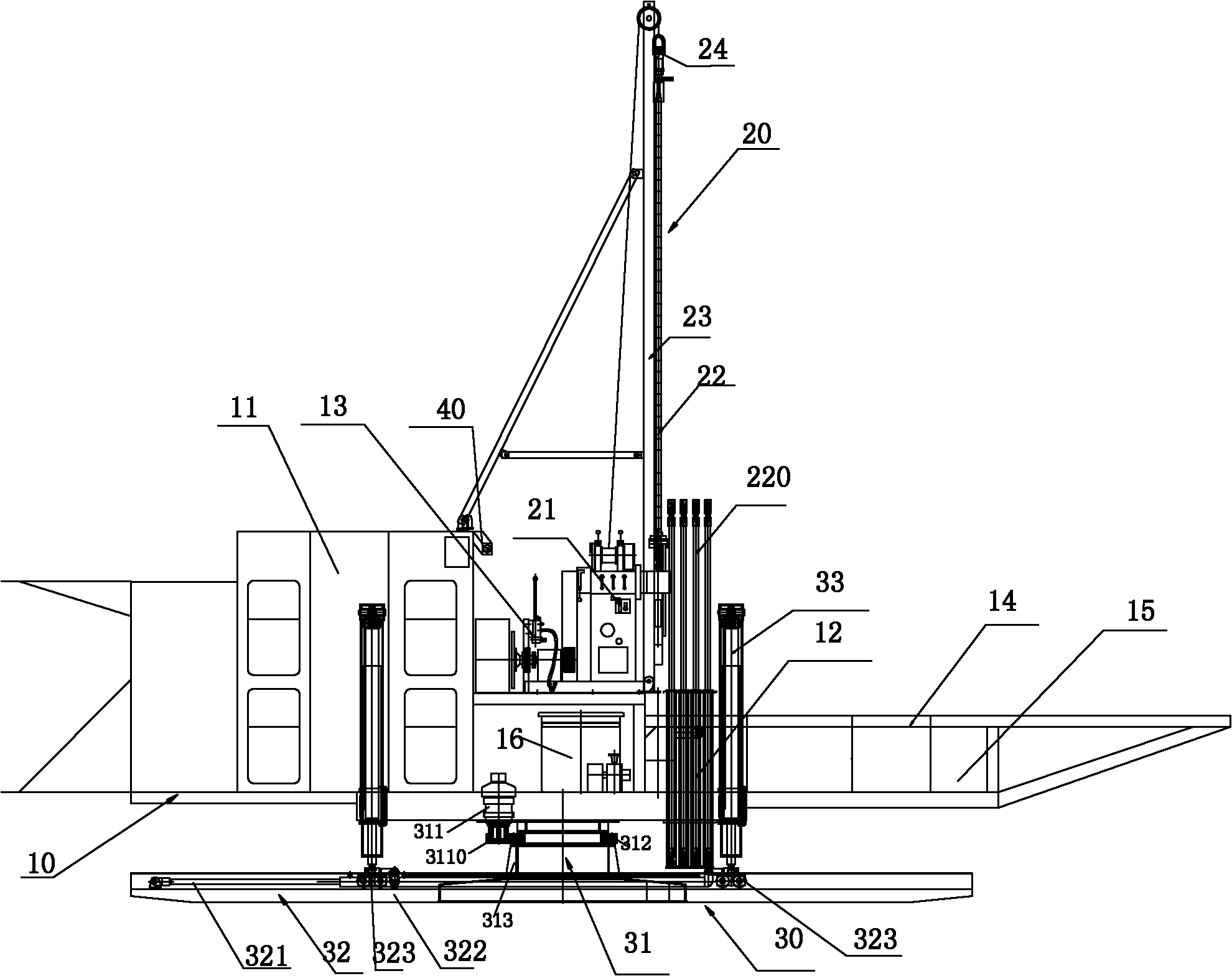

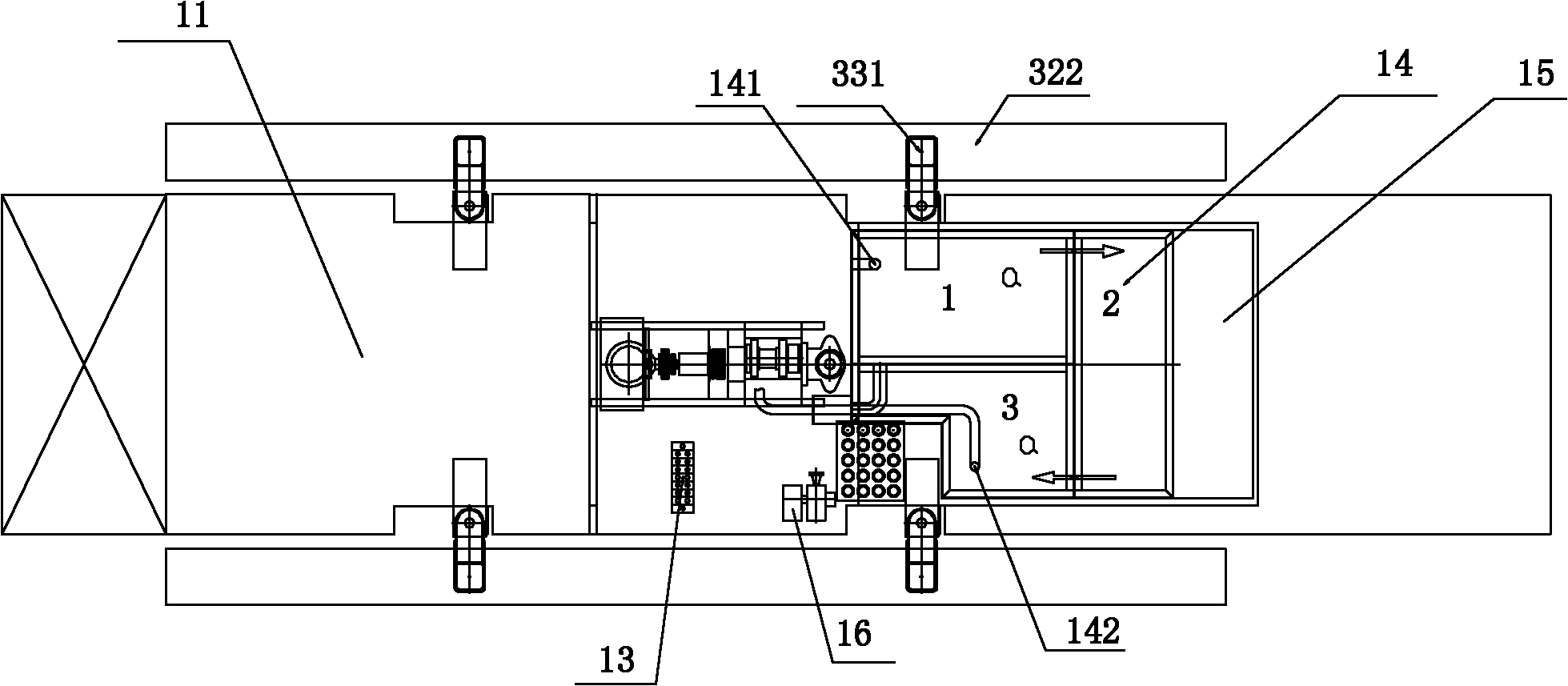

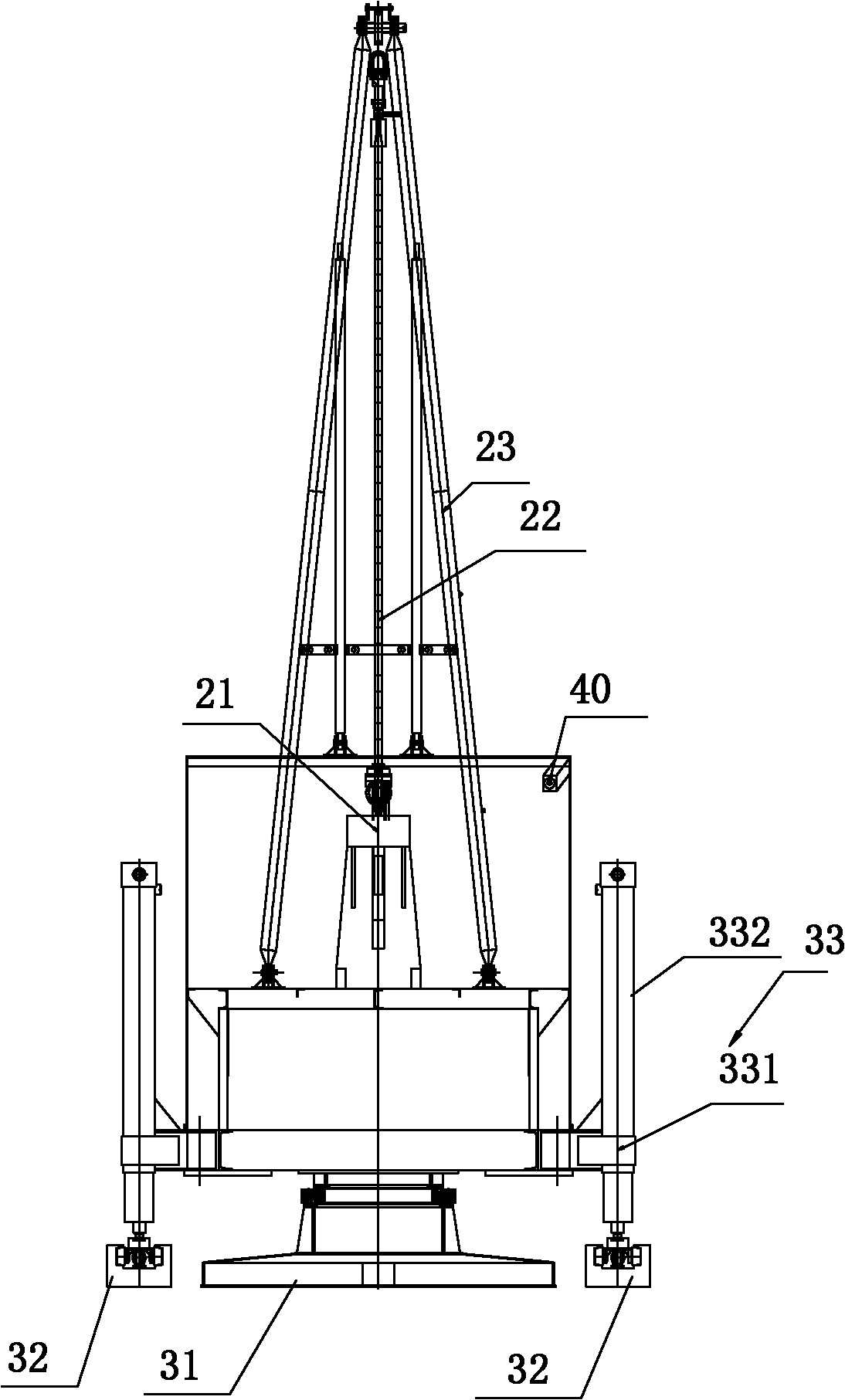

[0030] Such as Figure 1-Figure 4 As shown, the monitoring type walking drilling equipment includes a working platform 10 and a drilling device 20, and the drilling device 20 includes a drilling machine arranged on a working platform 21, a drilling rod 22 used by the drilling machine and a drilling frame 23, and the structure of the drilling device Appropriate structures in the prior art can be used, and will not be repeated here.

[0031]The monitoring walking drilling equipment also includes a fully rotating walking chassis 30 and a monitoring device 40 . The monitoring device 40 is arranged above the drilling device for real-time monitoring of the drilling operation. In this embodiment, the monitoring device 40 further includes an embedded digital hard disk video recorder, a waterproof infrare

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap