Photoetching machine worktable with driving device capable of balancing torque

A technology of driving device and balancing torque, applied in microlithography exposure equipment, photolithographic process exposure devices, etc., can solve the problems of interference, affecting control accuracy, and difficulty in the same height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

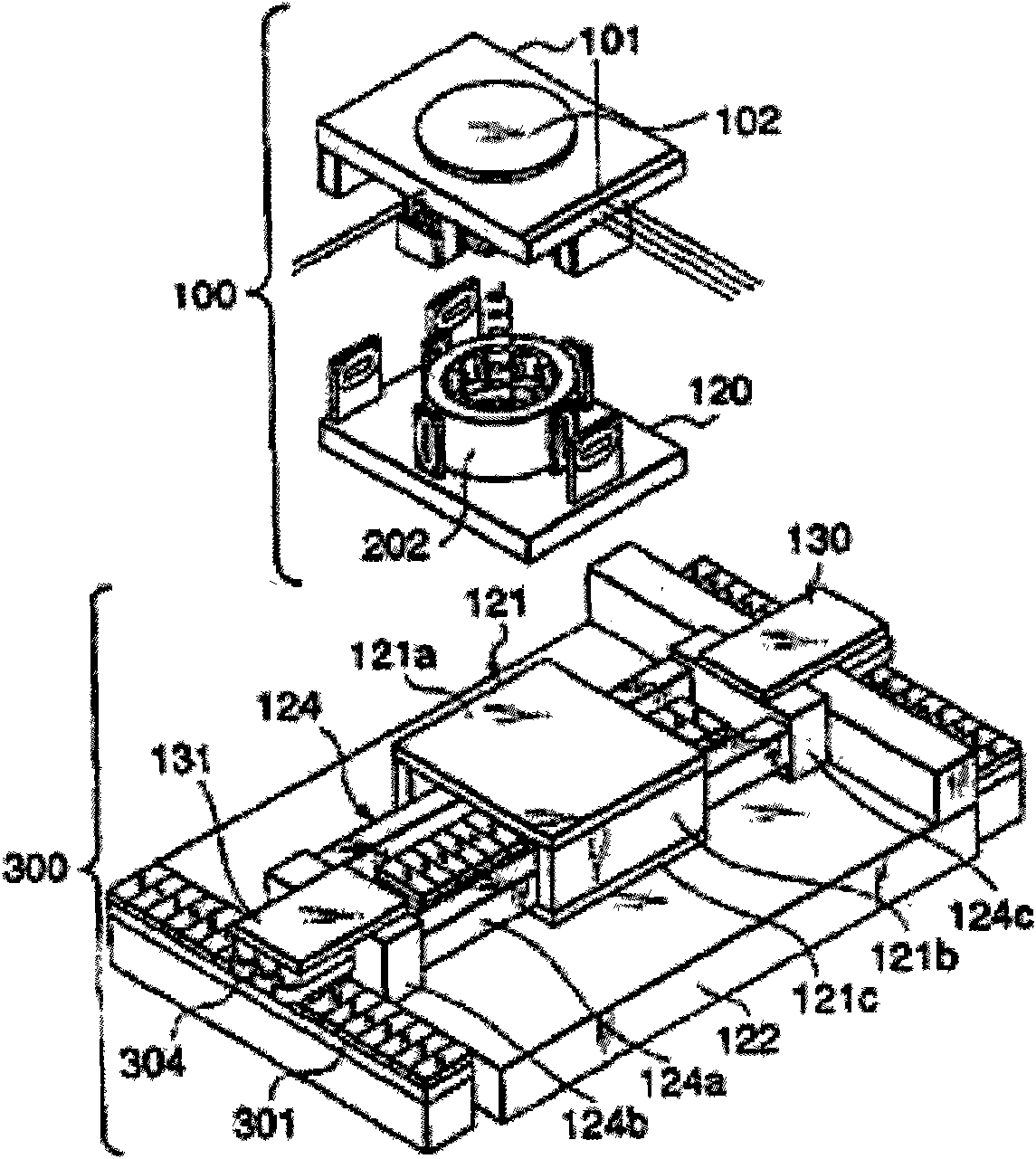

[0020] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

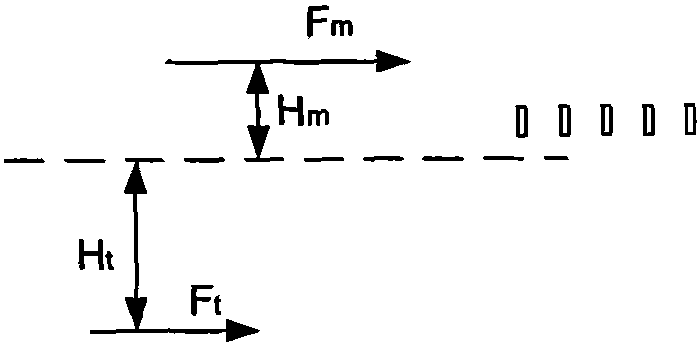

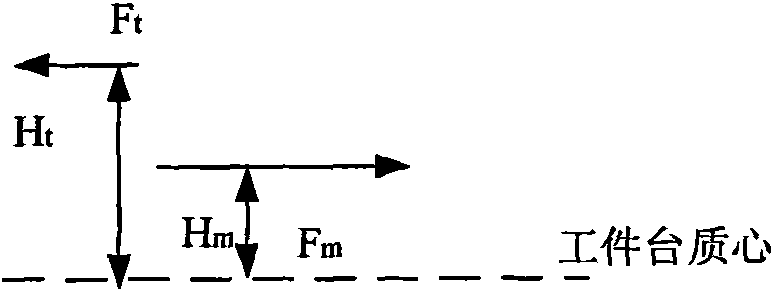

[0021] Please refer to Figure 2a ~ Figure 2c , Figure 2a ~ Figure 2c Shown is the schematic diagram of the moment compensation of the center of mass of the workpiece table of the lithography machine at different positions.

[0022] If the center of mass of the workpiece table is in the middle of the two motors, the mass of the workpiece table is M, and the acceleration is A, then the driving force F of motor 1-1 is compensated m and the force F driving the motor 1-2 t Then there is the following relationship:

[0023]

[0024]

[0025] where H m and H t represent the distances from the compensation motor and drive motor to the center of mass of the workpiece table respectively. In actual work, as long as the force F of the compensation motor 1-1 is controlled t The size of the additional

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap