Cloth cutting device of hole stitching machine

A technology for sewing machines and buttonholes, which is applied in the direction of sewing machine control devices, sewing machine components, and program-controlled sewing machines. Effects of misalignment, relaxation of contact pressure, and prevention of mutual damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

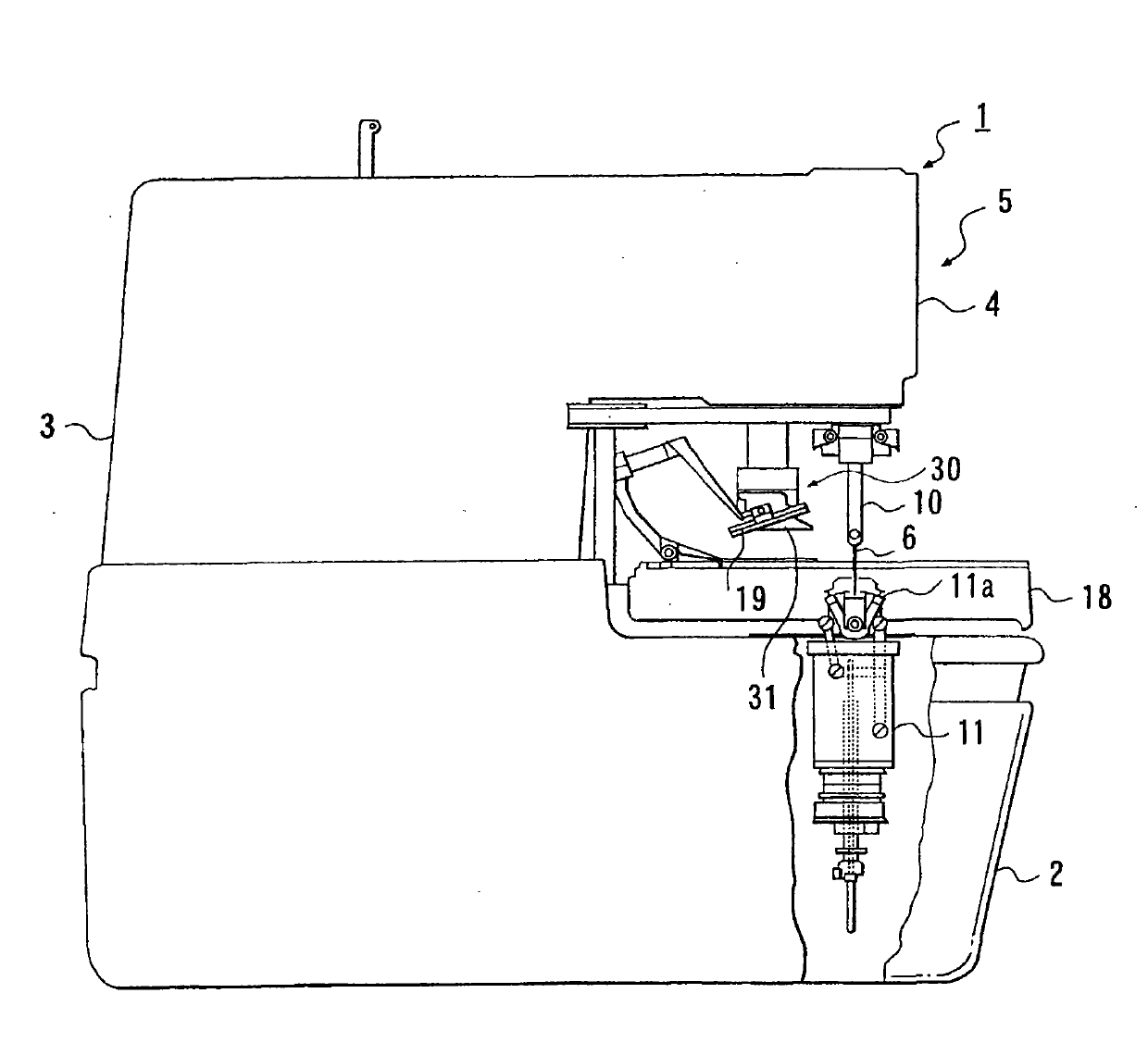

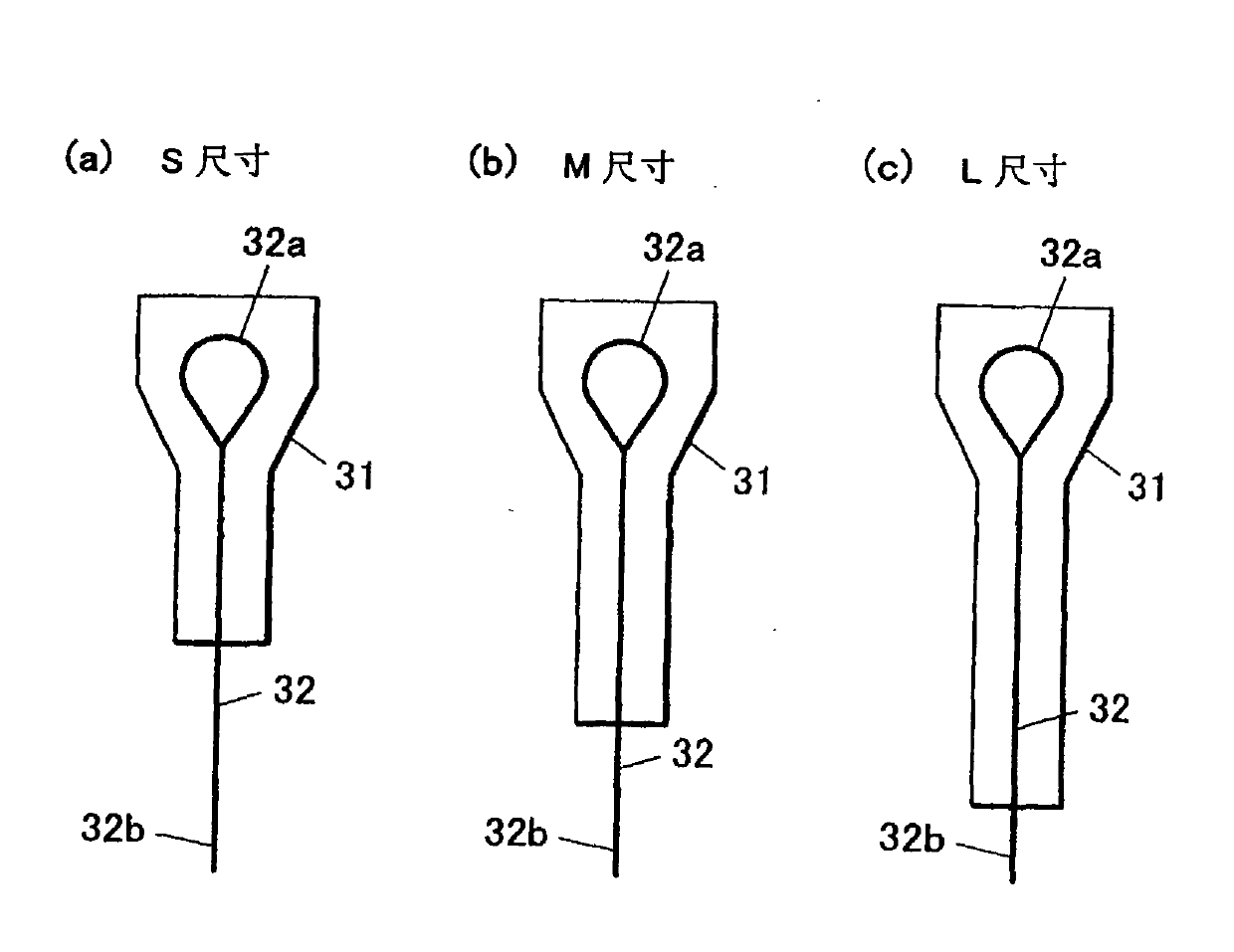

[0037] (Overall structure of buttonhole overlock sewing machine with round head)

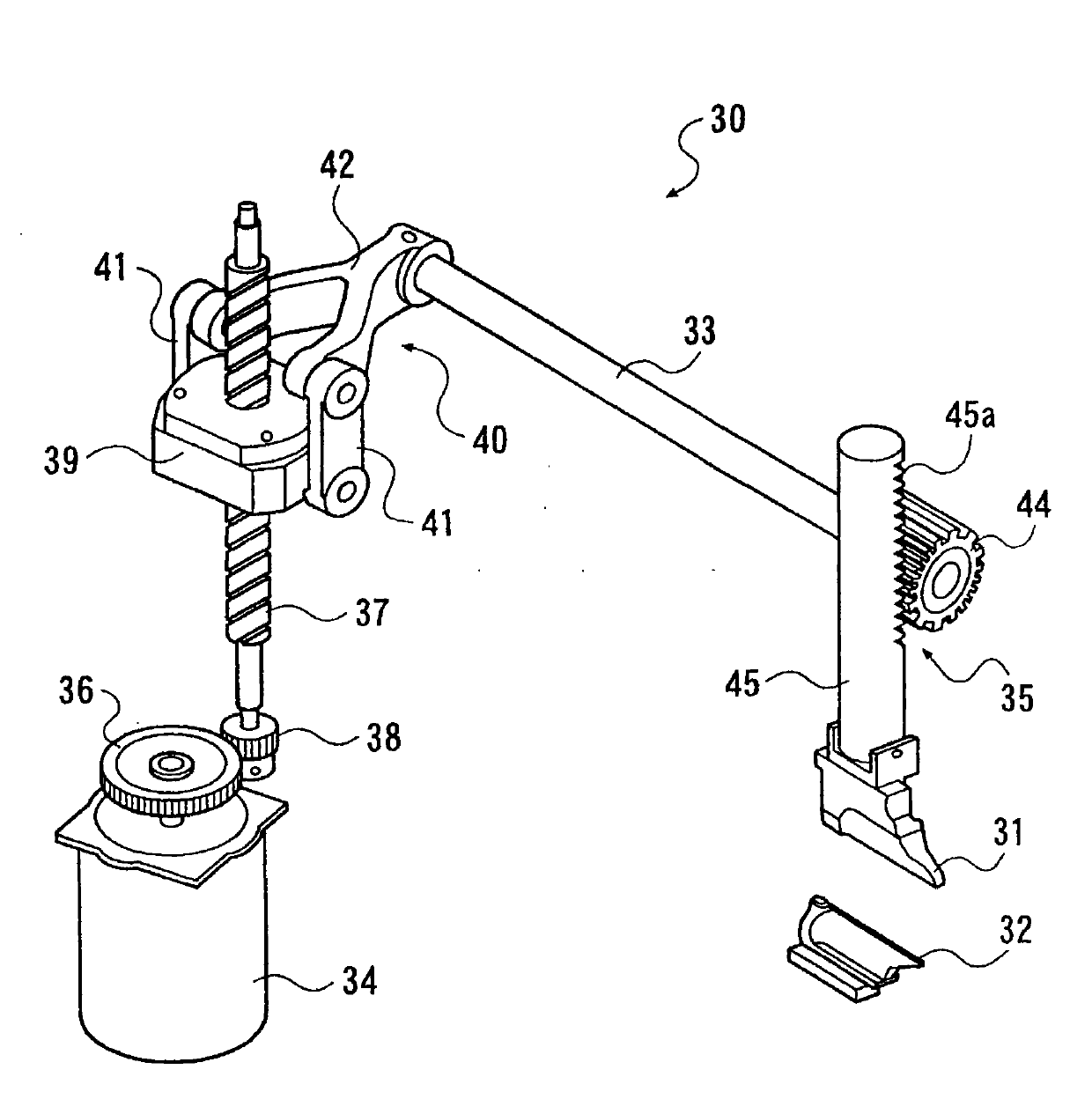

[0038] The cloth cutting device 30 in the embodiment of the present invention will be described with reference to the drawings.

[0039] Such as figure 1 As shown, there is a cloth cutting device 30 (in figure 2 The ball head buttonhole overlock sewing machine 1 shown in the figure) has a basic structure as a sewing machine for ball head buttonhole overlock sewing. The buttonhole sewing machine 1 has a sewing machine frame 5 and a sewing machine table on which the sewing machine frame 5 is placed. The sewing machine frame 5 has: a base part 2 formed in a substantially rectangular box shape; a longitudinal body part 3 provided on the base the rear part of the body part 2;

[0040] In addition, a needle bar 10 is provided at the front end of the arm 4, which extends downward, and has a sewing needle 6 at the lower end, which can move up and down and swing left and right. And, in the base part 2,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap