High-pressure paint film continuity tester

A continuity and tester technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of large waste, poor continuity of the paint film of the finished product line, and inability to reflect the truth, and achieve simple structure, reduced testing cost, and location Easy to set effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

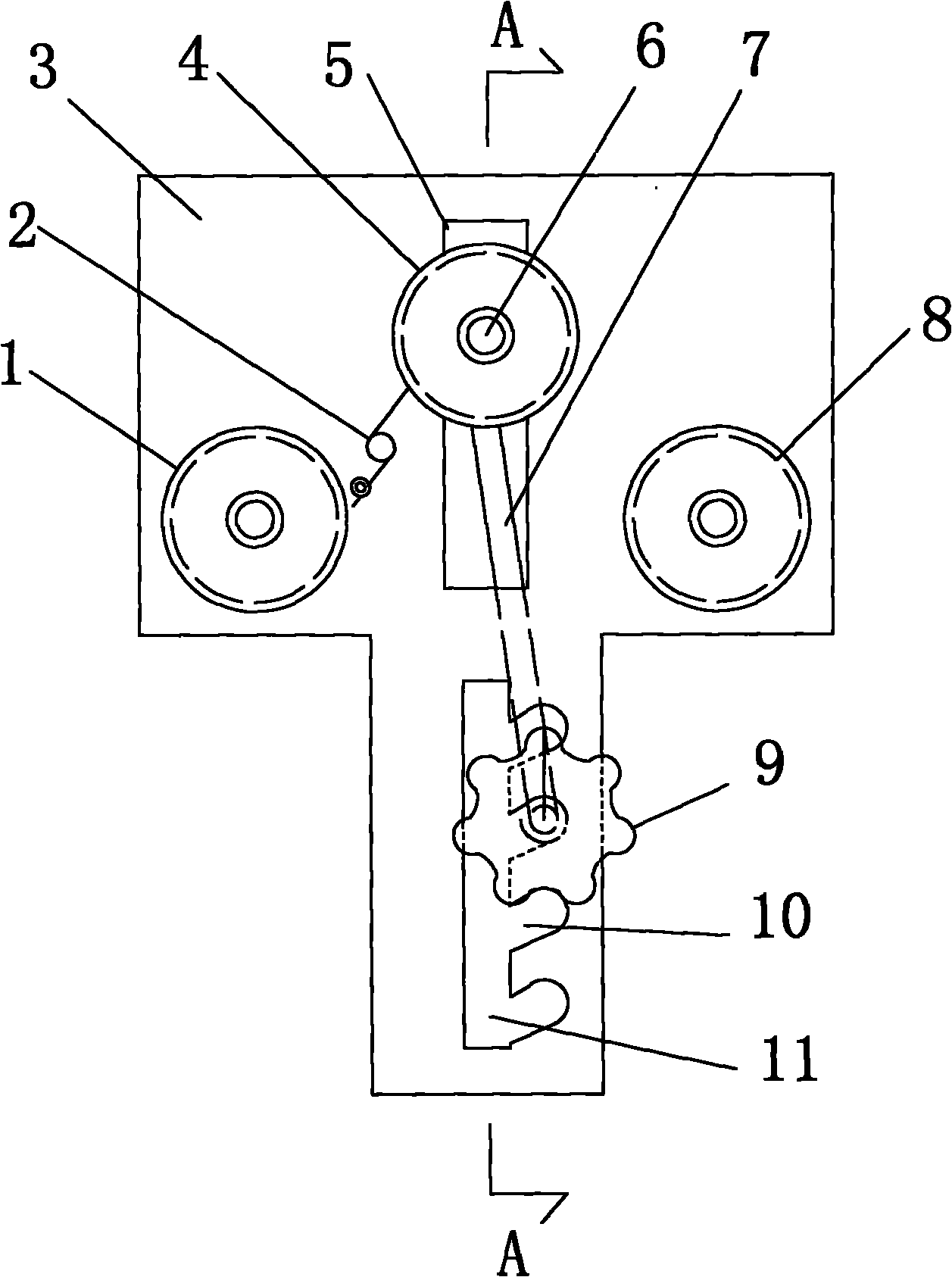

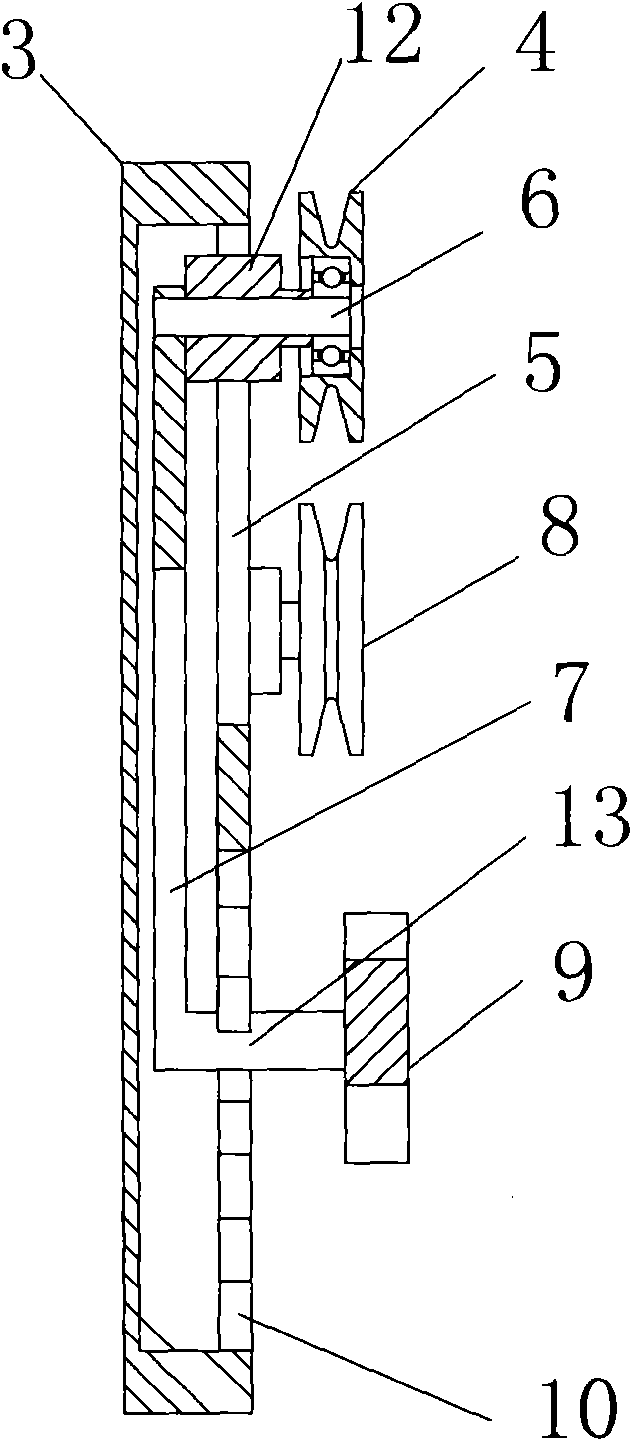

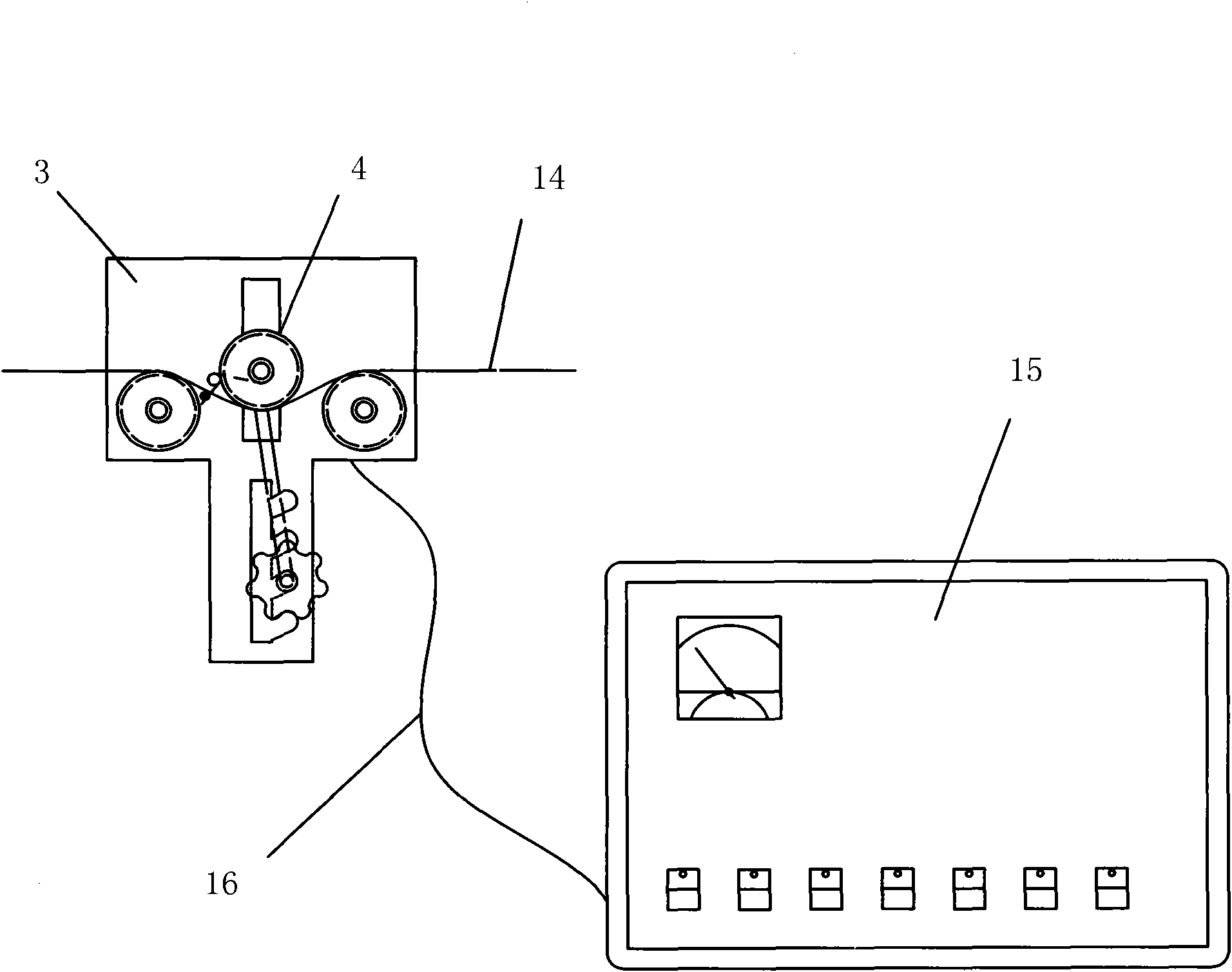

[0011] like figure 1 , figure 2 As shown, the high-voltage test head consists of a bracket 3, left and right guide wheels 1, 8 fixed on the bracket 3, and a pressure line wheel 4 located in the middle of the left and right guide wheels. The pressure line wheel 4 is fixed on the vertical displacement adjustment device. On the bracket 3, the vertical displacement adjustment device is a tie rod 7, and the bracket 3 is provided with a vertical guide groove 5 for the up and down movement of the pressure roller shaft 6, the slider 12 installed in the vertical guide groove 5, and the pressure roller shaft 6 and the slide. The block 12 is connected with a rotating width, the pull rod 7 is arranged under the pressure wire wheel 4, the upper end of the pull rod 7 is hinged on the pressure wire wheel shaft 6, the lower end of the pull rod 7 is connected with a positioning pin 13 perpendicular to the pull rod 7, and the bracket 3 is provided with a pull rod. The vertical guide groove 11 th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap