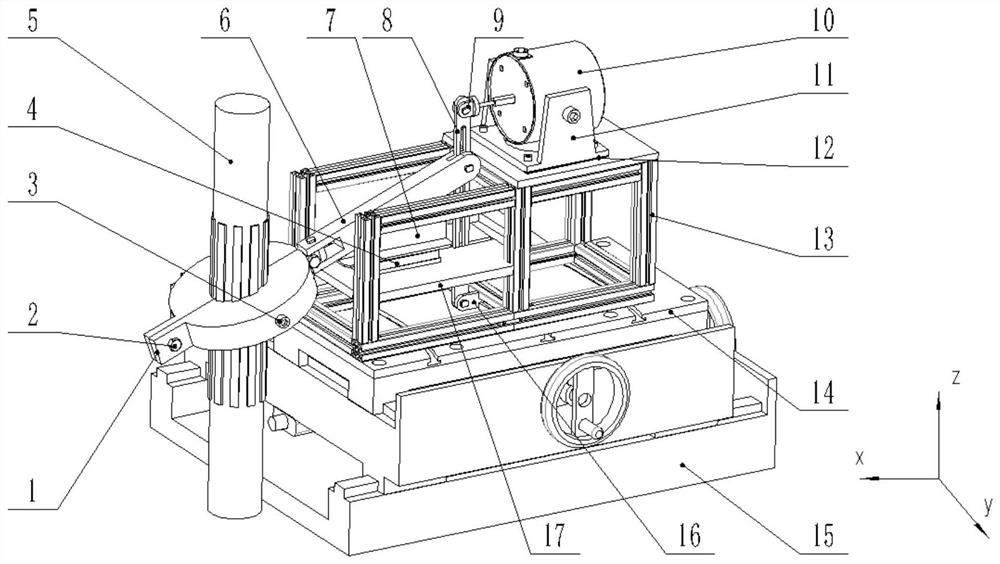

Turning and rolling compound machine tool simulation cutting loading device and using method

A compound machine tool and loading device technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as low applicability, inability to simulate machine tool processing conditions, and inability to fully simulate machine tool loading force, etc., to achieve applicable Highly Reliable, Inexpensively Tested, Powerful Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

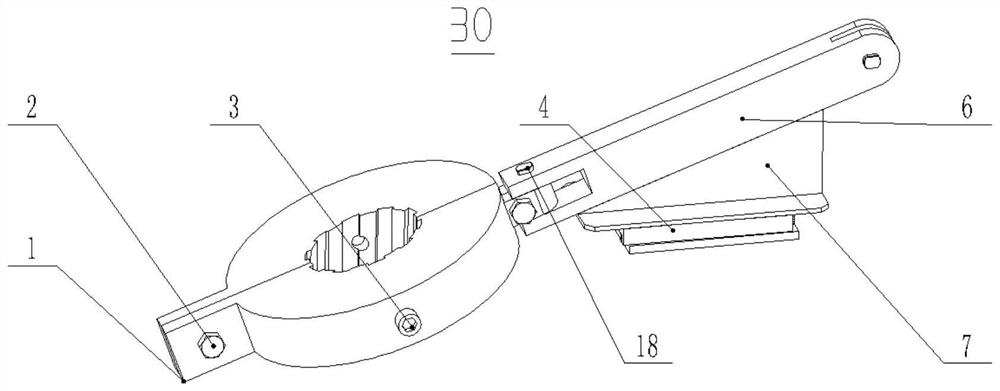

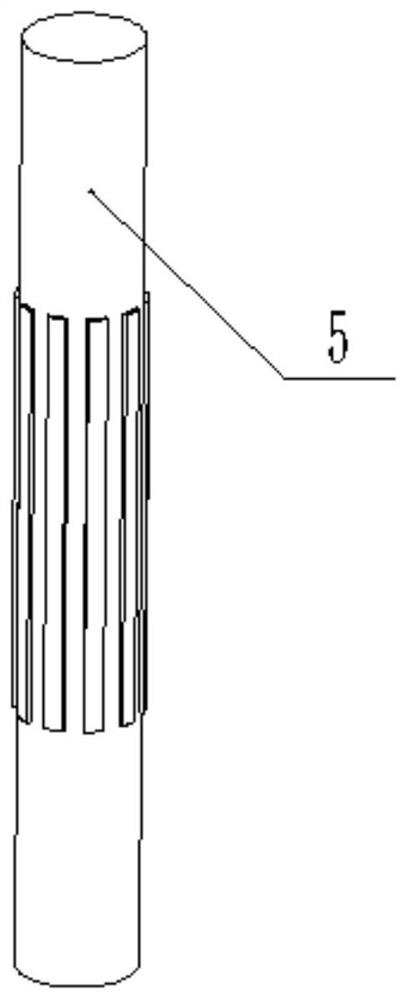

[0045]In order to facilitate understanding of the invention, the present invention will be further described below with reference to the accompanying drawings and specific embodiments. The preferred embodiment of the present invention is given in the drawings. However, the present invention can be implemented in many different forms, is not limited to the embodiments described herein. Conversely, the purpose of providing these embodiments is to make the disclosure of the present invention more thoroughly.

[0046]It should be noted that when the element is referred to as "fixed to" another element, it can be directly in another element or may also exist. When a component is considered to be "connected" another element, it may be directly connected to another element or may always exist in the center element. The term "vertical", "horizontal", "left", "right", "left", "right", and similar expressions are not shown as unique embodiments.

[0047]All techniques and scientific terms used herein

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap