Insert mold structure for shower head

A technology for showers and moulds, which is applied to home appliances, other home appliances, and household components. It can solve the problems of difficult mold exhaust, difficult removal, and trapped air in lower mold products, so as to save flash removal process, easy to remove, Easy exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

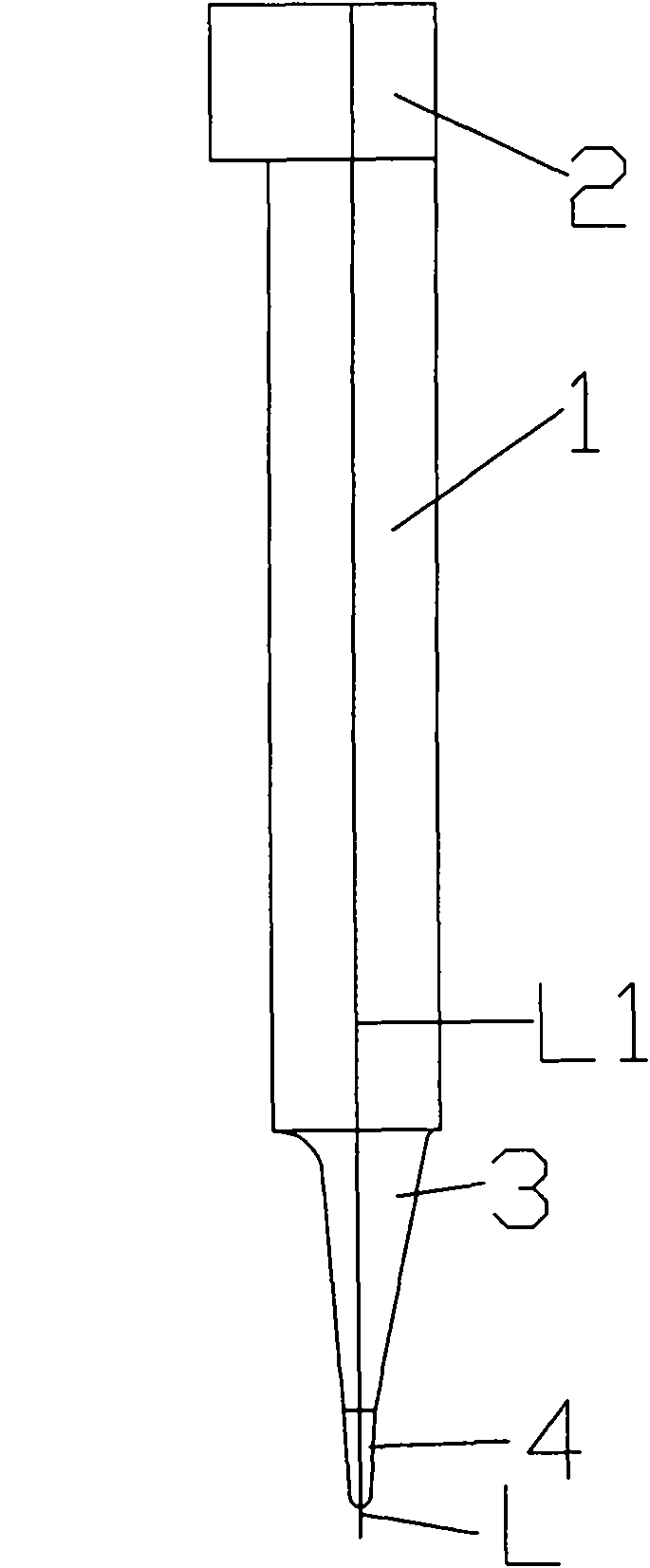

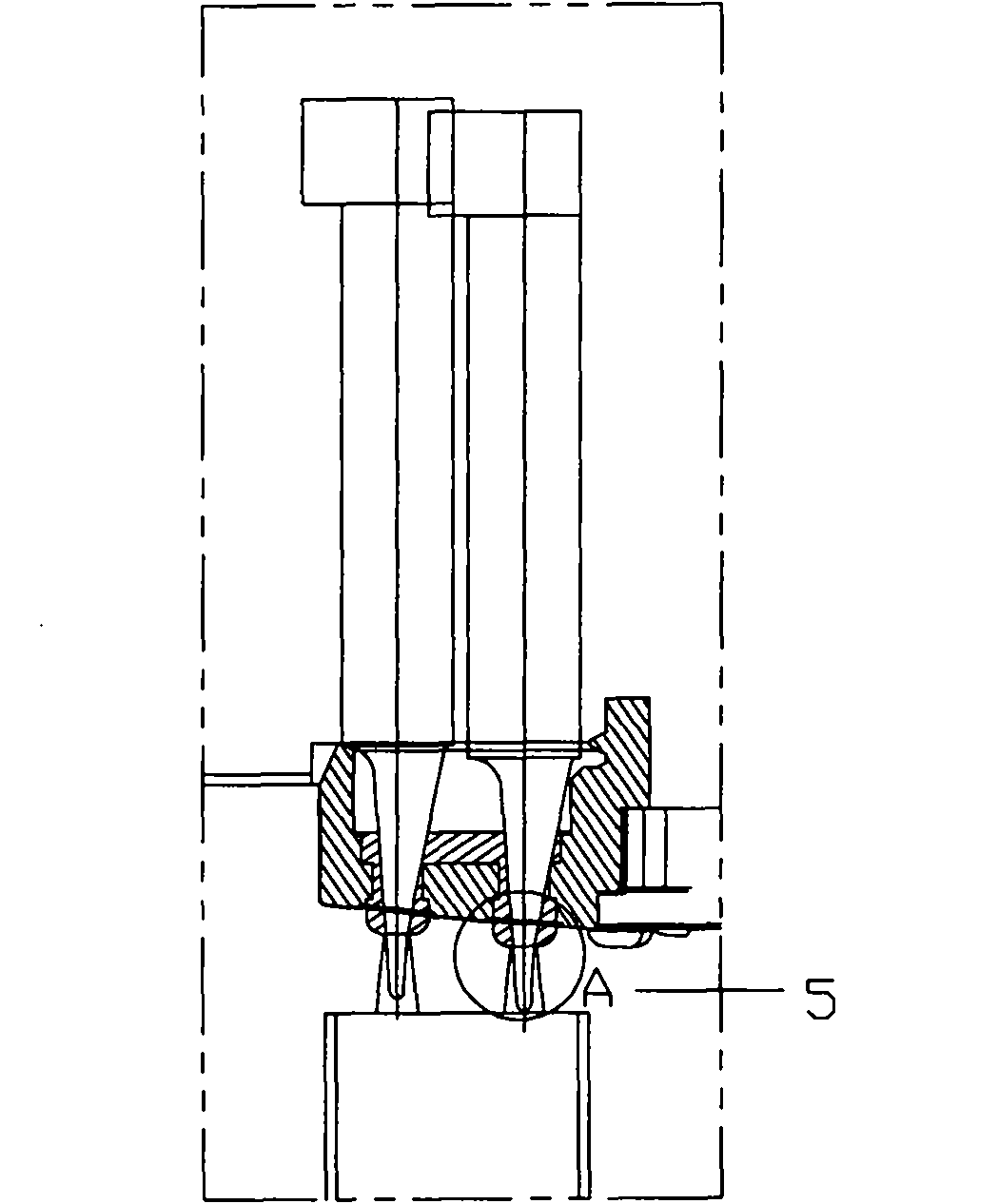

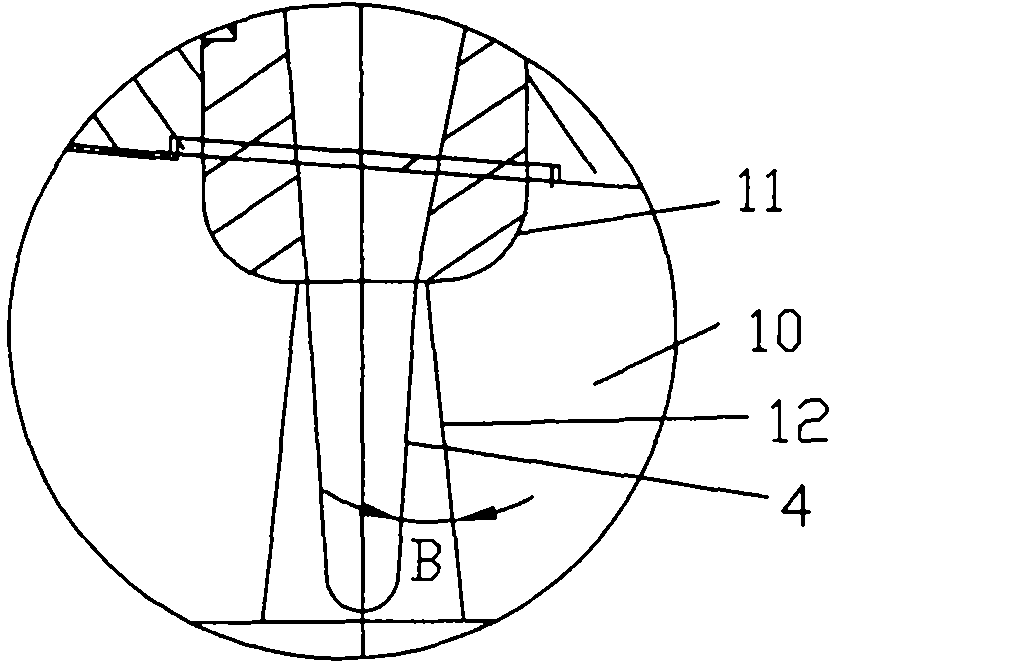

[0015] Such as figure 1 As shown, a shower insertion mold structure of the present invention includes an insert 5 used to form the outer structure of the shower and an insertion needle for forming the shower hole; the insertion needle includes a main body 1, and a set The hanging table 2 at the upper end of the main body part 1, the first molding part 3 which is arranged at the lower end of the main body part 1 and is used to form the water outlet, and the inserting needle end part 4 connected with the main body part 1, the insertion The axis L of the insert end 4 is on the same straight line as the axis L1 of the first molding part 3, and the end is basically symmetrically inserted through the insert with the axis as the center, and the exhaust is smooth during molding, and the insert end is inserted The part is not easy to be worn with the insertion hole insert of the rear mold, and the vertical flash produced is thin and uniform, and is easy to remove; the end of the insertion

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap