Machine tool bed

A bed and machine tool technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient stability and mechanical properties to be strengthened, and achieve the improvement of mechanical properties, enhanced mechanical properties, and increased bed width. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

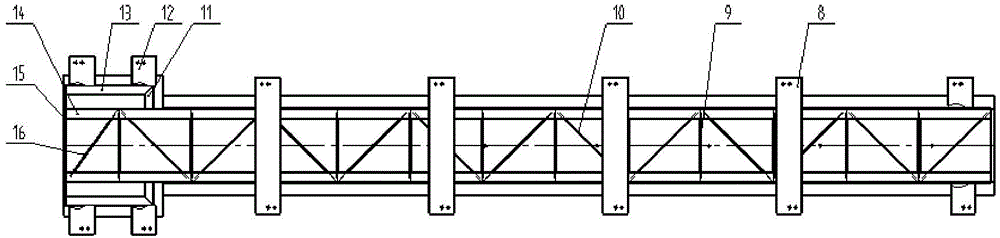

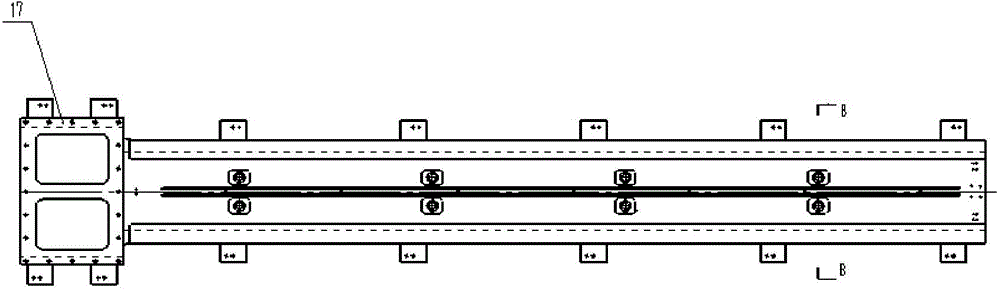

[0027] Such as Figure 1-6 As shown, a machine tool bed includes a bed body, and the bed body includes a head and a tail. The upper part of the head is a top plate 17 provided with several mounting holes and two mounting square grooves. The side of the top plate 17 is along the bed The second end plate 15 is arranged downwards in the height direction of the body, two evenly distributed long anchor plates 12 are arranged at the lower part of the head, five evenly distributed anchor plates 8 are arranged at the lower part of the tail, and a long anchor plate 12 and an anchor plate 8 are arranged above a The third rib plate 16 and the twelve second rib plates 10 are provided with two mutually symmetrical third hot-rolled grooved tubes 14 on both sides of the plate, and every two second rib plates 16 form an acute angle structure along a straight lin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap