Elastic compaction mechanism of air cylinder and valve plate assembly for refrigeration compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

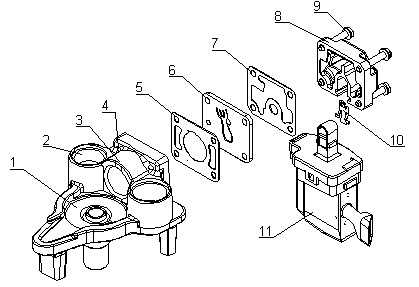

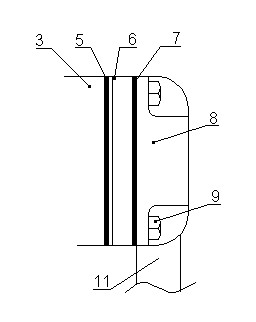

Image

Examples

Embodiment Construction

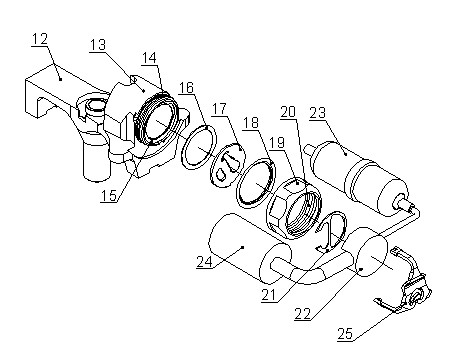

[0012] like image 3 As shown, the cylinder head structure of the refrigeration compressor of the present invention includes a crankcase 12, a valve plate gasket 16, a valve plate assembly 17, an elastic gasket 18, a threaded sleeve 19, a cylinder head gasket 21, a cylinder head 22, and a circlip 25 , Exhaust muffler 23 and suction muffler 24, crankcase 12 is provided with cylinder 13, the outside of the end of cylinder 13 is provided with external thread 14, the inside of end of cylinder 13 is provided with step hole 15, and thread sleeve 19 is provided with There are 20 internal threads. Elastic spacer 18 is provided with fixed plane 31 and contact curved surface 32 (please also refer to Figure 4 ).

[0013] like image 3 and Figure 4 As shown, the installation of the refrigeration compressor cylinder head of the present invention is divided into three steps: the first step is to fasten the fixed plane 31 of the elastic gasket 18 on the outer surface of the valve plate as

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap