Ultra-high pressure device based on hinged-type hexahedral press

A hexahedral, ultra-high pressure technology, applied in the process of applying ultra-high pressure and other directions, to achieve the effects of superior overall performance, increased service life, and quick installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 Illustrates the structure of the present invention in conjunction with the accompanying drawings

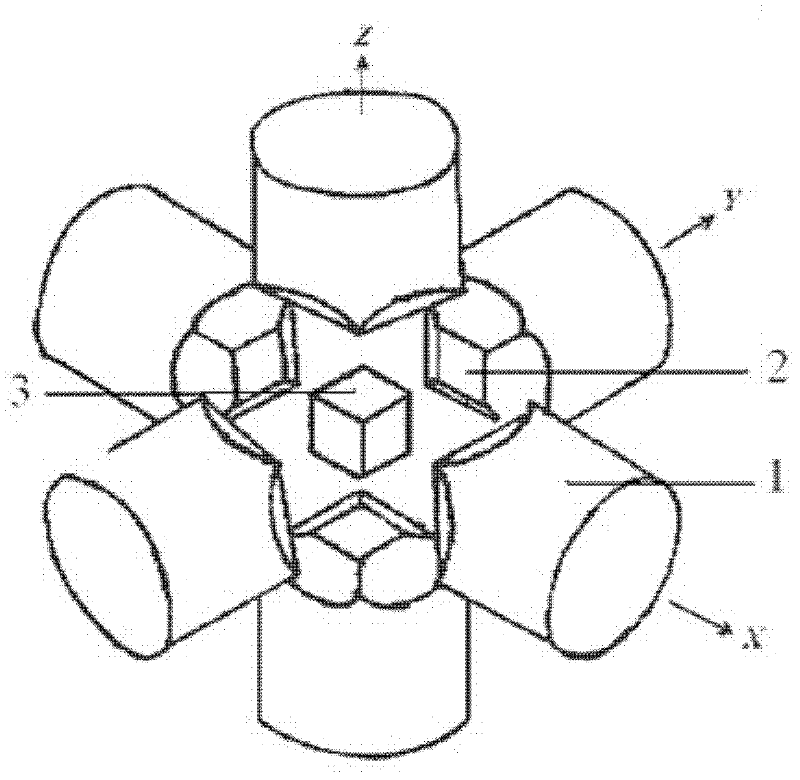

[0024] The novel device for generating static high pressure of the present invention is based on the hexahedron press frame of hinged frame (its structure is as follows: figure 1 Shown) hexahedral large cavity static high pressure device.

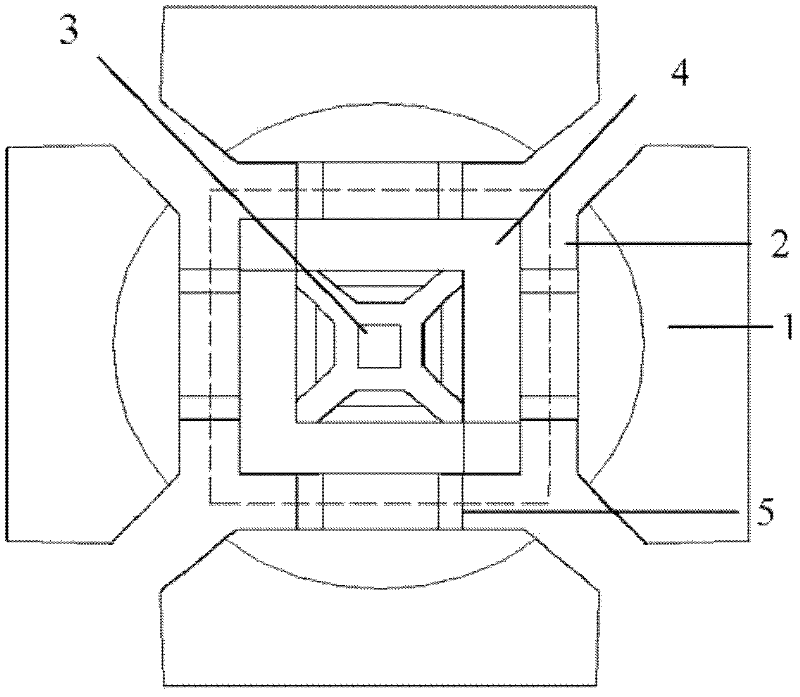

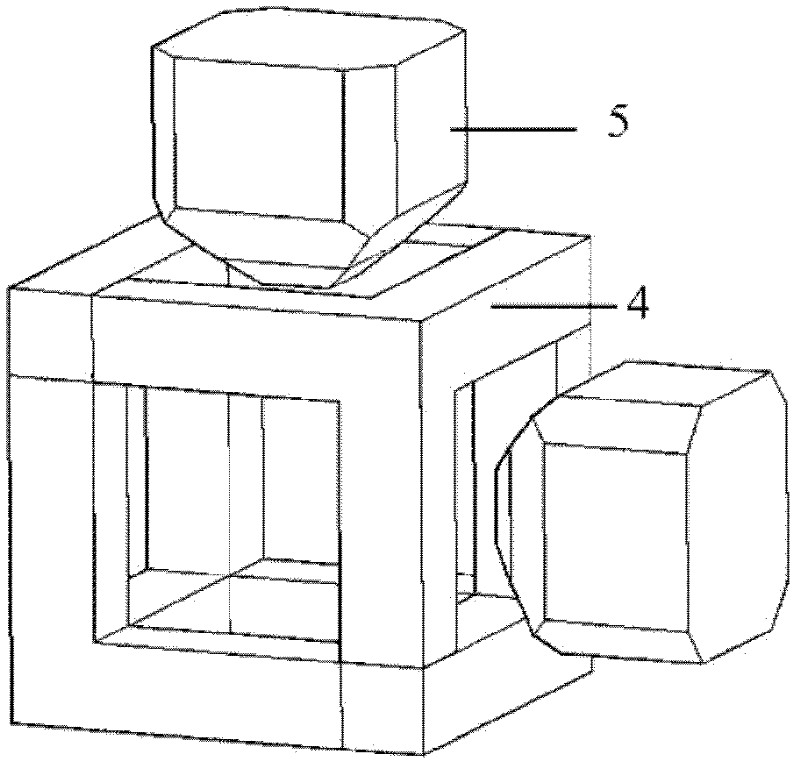

[0025] The plane schematic diagram of the ultra-high pressure device based on the hinged hexahedron press of the present invention is as follows figure 2 shown. exist figure 1 , 2 Among them, 1 is the anvil of the press, which is a cemented carbide anvil driven by the hydraulic pressure of the hexahedron press, and there are six in total; 2 is the anvil surface of the anvil of the press; 3 is a synthetic block, which is in the shape of a cube and contains synthetic materials; 5 is a pressurized anvil, the shape of a kind of pressurized anvil 5 of the present invention can refer to Figure 6 , Figure 6 Its cross-section

Embodiment 2

[0027] Embodiment 2 Specific examples

[0028] 1. For example, WC is selected as the material of the hexahedral press anvil 1 (top hammer), and when the size of the anvil surface is 23.5*23.5mm, the side length of the bottom surface of the pressurized anvil 5 is selected to be 14.5*14.5mm. The side length of the small surface of the pressurized anvil 5 can be changed in the range of 1-4 mm, so that different sizes and pressures of the high-pressure synthesis chamber can be obtained. When the side length of the small surface of the pressurized anvil 3 is 3mm, the pressure of the high-pressure cavity can reach 23GPa;

[0029] At this time, the pressurized anvil bracket 6 is made of alloy steel, the cross-section of the three square columns is 4.5*4.5mm, the length of the two short square columns is 14.5mm, and the length of the other long square column is 19mm.

[0030] 2. For example, WC is selected as the material of the anvil 1 (top hammer) of the hexahedral press, and when the s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap