Preparation method and application of coal and oil co-refining catalyst

A catalyst and co-refining technology, used in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc., can solve the problems of complex synthesis process of catalysts for kerosene co-refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

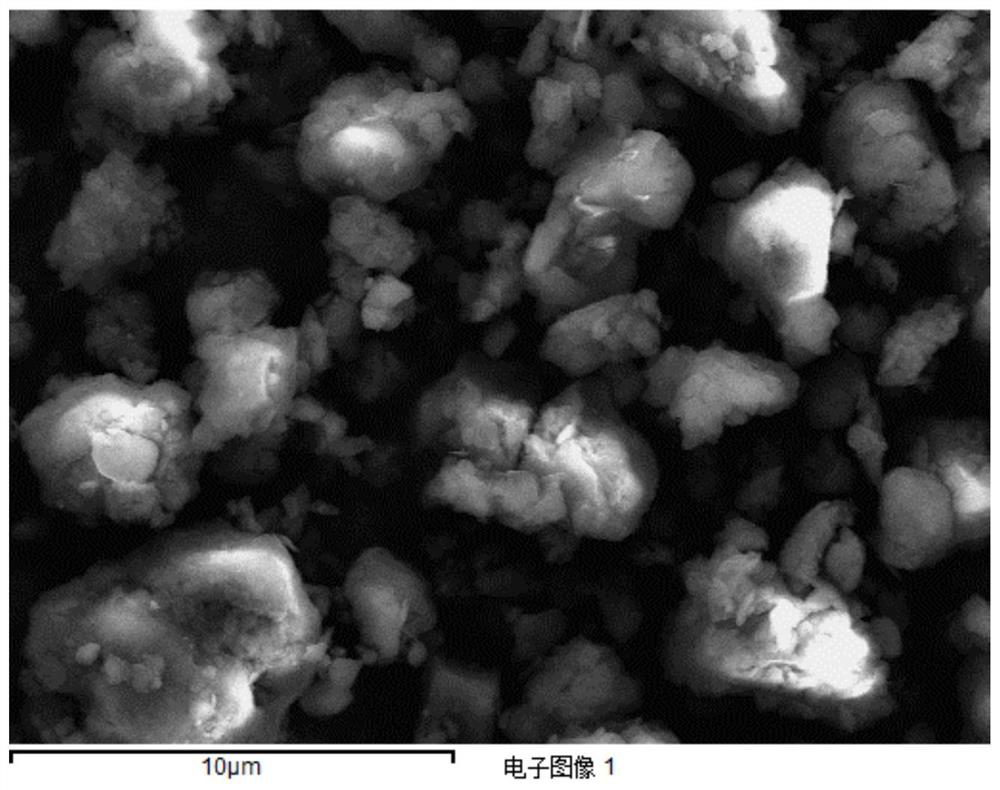

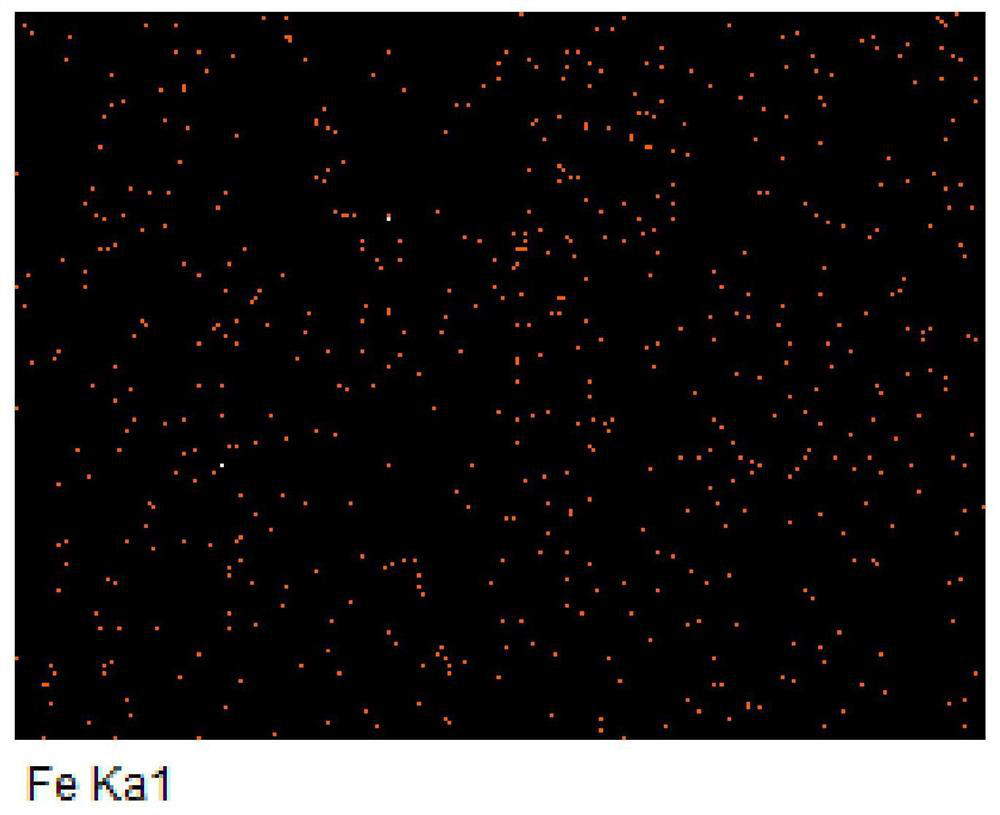

Image

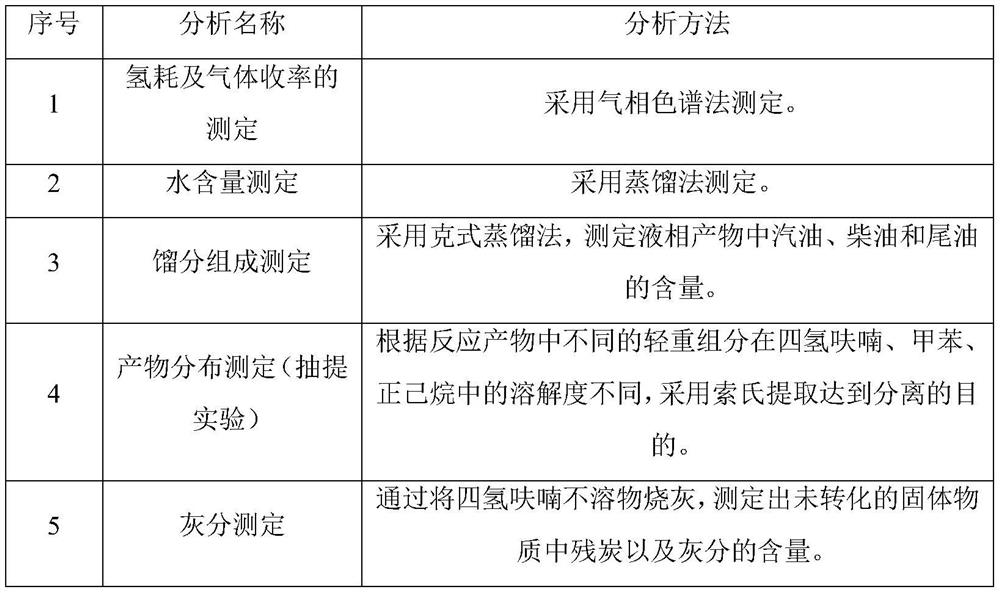

Examples

Embodiment 1

[0024]0.1 mol (27.8 g) of the ferrous sulfate dissolved in 500 ml of deionized water, 30 ° C After stirring, the ferrous sulfate solution was obtained, 0.02 mol (5.8) hexahydrate nickel, to give sulfuric acid of mixed metal ions The ferrous solution was added 0.5 mol (30.0 g) of urea, warmed to 90 ° C, remained continuously stirred for 6 h, resulting in a slurry, dried 6 hours at 60 ° C, resulting in a coal oil according to the present invention. Catalyst, recorded as CAT-1.

Embodiment 2

[0026]In Example 2, 0.24 mol (14.4 g) of urea was added, and the temperature was continuously stirred at 100 ° C, and the slurry was filtered, 6 hours at 100 ° C; Example 1 was identical to obtain a catalyst, which was recorded as CAT-2.

Embodiment 3

[0028]In Example 3, the ferrous sulfate was replaced with iron sulfate to iron sulfate hydrate, and nickel nitrate was replaced with nickel (1.5 g) of hexahydrate nitrate, and the remaining operation As in Example 1, a catalyst was obtained as CAT-3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap