Method and device for temperature management of exhaust purification equipment

A technology of exhaust gas purification and equipment, which is applied in the direction of electric control of exhaust treatment devices, exhaust devices, exhaust treatment, etc., can solve the problems of unrelated use, insufficient inclusion of thermoelectric generators, etc., and achieve the effect of improving thermal protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

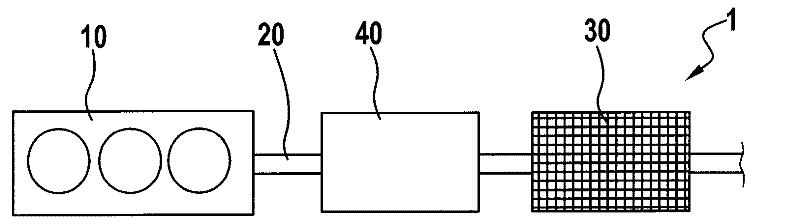

[0040] figure 1 An internal combustion engine 1 is schematically shown with a cylinder bank 10 and an exhaust gas purification system 40 arranged in an exhaust gas duct 20 . The thermoelectric generator 30 is mounted on the exhaust gas purification device 40 upstream of the exhaust gas purification device 40 in the flow direction of the exhaust gas in such a way that it is heated from one side of the hot exhaust gas, while the other side is directed outwards and has a lower temperature. As described above, electrical energy can thus be detected from the thermal energy contained in the exhaust gas. This arrangement is particularly suitable to protect the exhaust gas aftertreatment device 40 from too high temperatures and thus possible thermal damage if the thermoelectric generator 30 is operated in generator mode and thus can extract thermal energy from the exhaust gas.

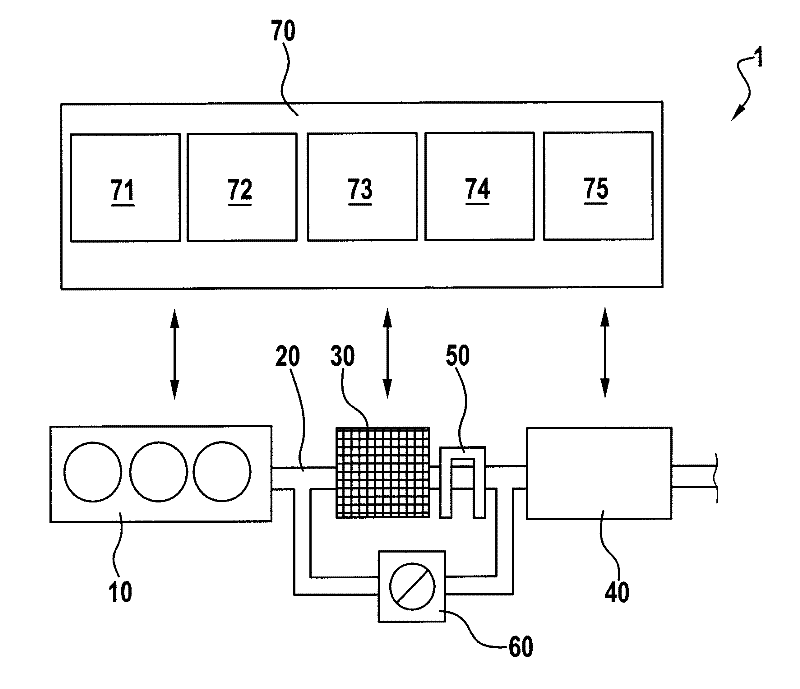

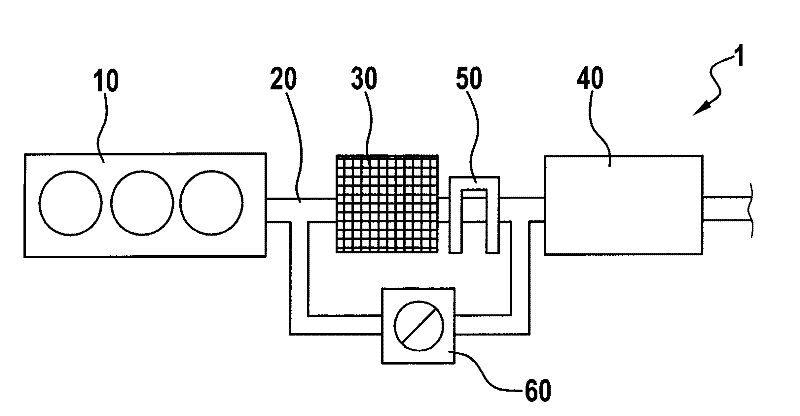

[0041] exist figure 2 Also schematically shows an arrangement in which the thermoelectric generator 30 is c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap