Engine emergency stop device and emergency stop function test method

A technology for emergency shutdown and functional testing, which is applied in engine testing, engine components, engine control, etc. It can solve problems such as emergency shutdown air pipeline corrosion and blockage, damaged diesel engine, emergency shutdown solenoid valve stuck, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

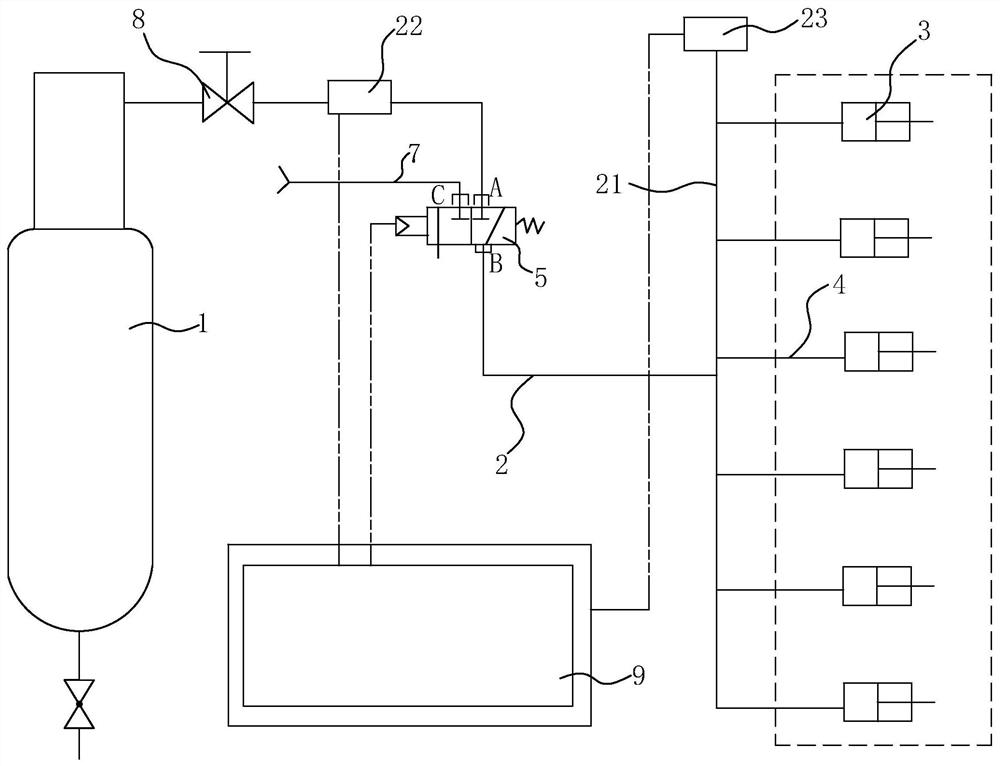

[0032] Depend on figure 1 As shown, in this embodiment, the engine emergency stop device includes a compressed air supply unit 1, an air supply pipeline 2 and a plurality of parking cylinders 3 arranged side by side, and the air supply pipeline 2 is connected to the air outlet of the compressed air supply unit 1, and a plurality of The parking cylinder 3 communicates with the converging pipe section 21 of the air supply pipeline 2 through a one-to-one corresponding branch pipeline 4, and an electric control valve is arranged on the air supply pipeline 2; There is a first pressure sensor 22 , and a second pressure sensor 23 is provided on the junction pipe section 21 ; the electric control valve, the first pressure sensor 22 and the second pressure sensor 23 are all electrically connected to the control unit 9 . A cut-off check valve 8 is arranged on the gas supply pipeline 2 upstream of the electric control valve.

[0033] The electric control valve in this embodiment is a two-p

Embodiment 2

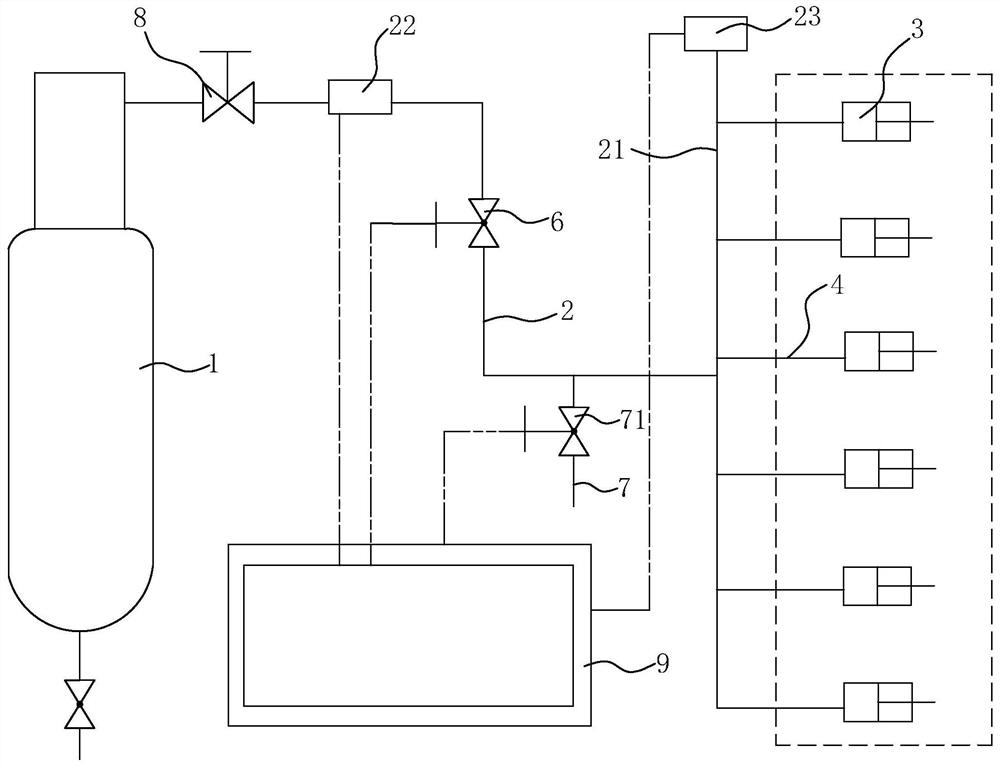

[0035] The structure of this embodiment is basically the same as that of Embodiment 1, the difference lies in the electric control valve, and only the differences will be described below.

[0036] Depend on figure 2 As shown, the electric control valve in this embodiment is a two-position two-way solenoid valve 6, and the gas supply pipeline 2 downstream of the two-position two-way solenoid valve 6 communicates with the discharge pipeline 7, and the discharge pipeline 7 is provided with a discharge pipeline. Release valve 71; when the two-position two-way solenoid valve 6 is opened (the gas supply pipeline 2 is turned on), the relief valve 71 is closed (the discharge pipeline 7 is cut off), and when the two-position two-way solenoid valve 6 is closed (the gas supply pipeline 2 cut-off), the discharge valve 71 is opened (the discharge pipeline 7 is conducted); it should be noted that opening and closing refer to the opening and closing state of the valve.

[0037] Wherein, the t

Embodiment 3

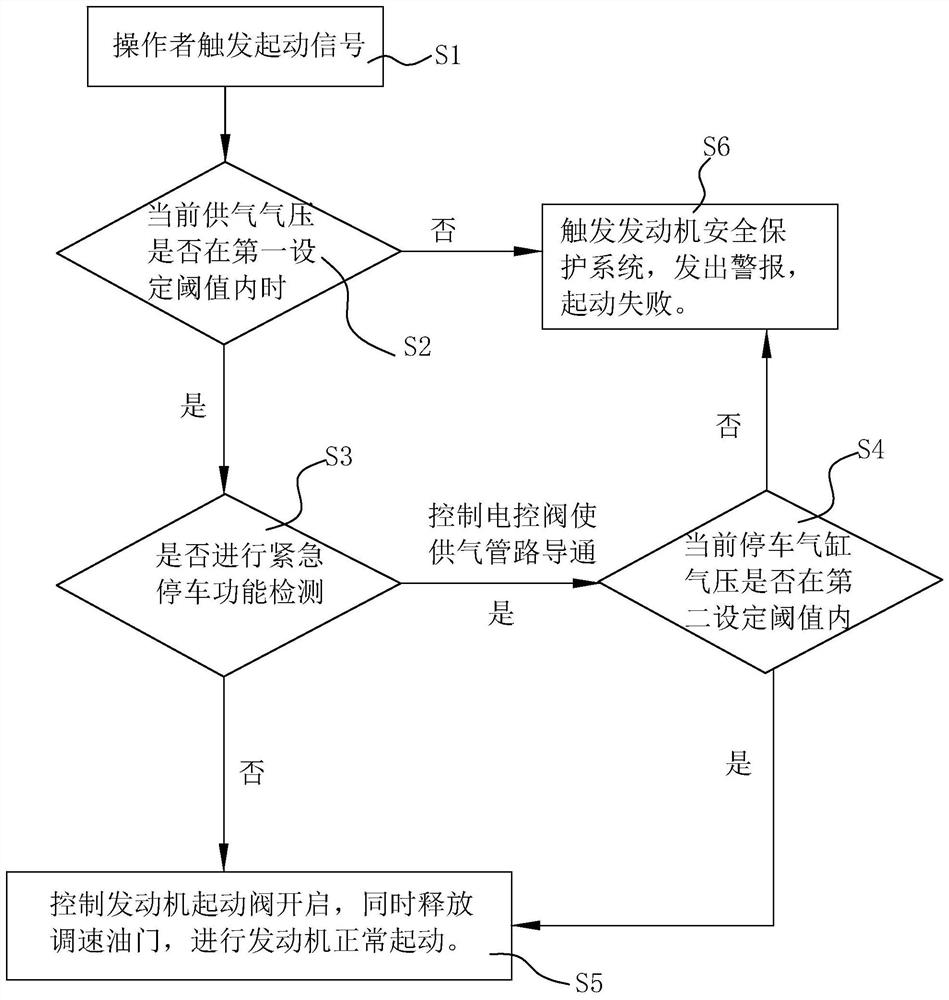

[0039] Depend on image 3 As shown, this embodiment discloses a method for testing the emergency stop function, and the emergency stop function is tested based on the engine emergency stop device disclosed in Embodiment 1 or Embodiment 2; including:

[0040] S1. The operator triggers the start signal.

[0041] S2. Based on the pressure signal transmitted by the first pressure sensor 22, the control unit 9 judges whether the current supply air pressure is within the first set threshold; when it is determined that the current supply air pressure is within the first set threshold, execute step S3 ; When it is determined that the current supply air pressure is not within the first set threshold, execute step S6.

[0042] S3. The control unit 9 issues a selection command, and the display unit electrically connected to the control unit 9 prompts the operator to choose whether to perform an emergency stop function test; when the operator chooses to perform an emergency stop function test

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap