Automatic measuring instrument for crystal inflection point of oven-controlled crystal oscillator (OCXO)

A technology of constant temperature crystal oscillation and crystal oscillator, applied in the direction of frequency measurement devices, etc., can solve the problems of rework and retest, low efficiency, long measurement time, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

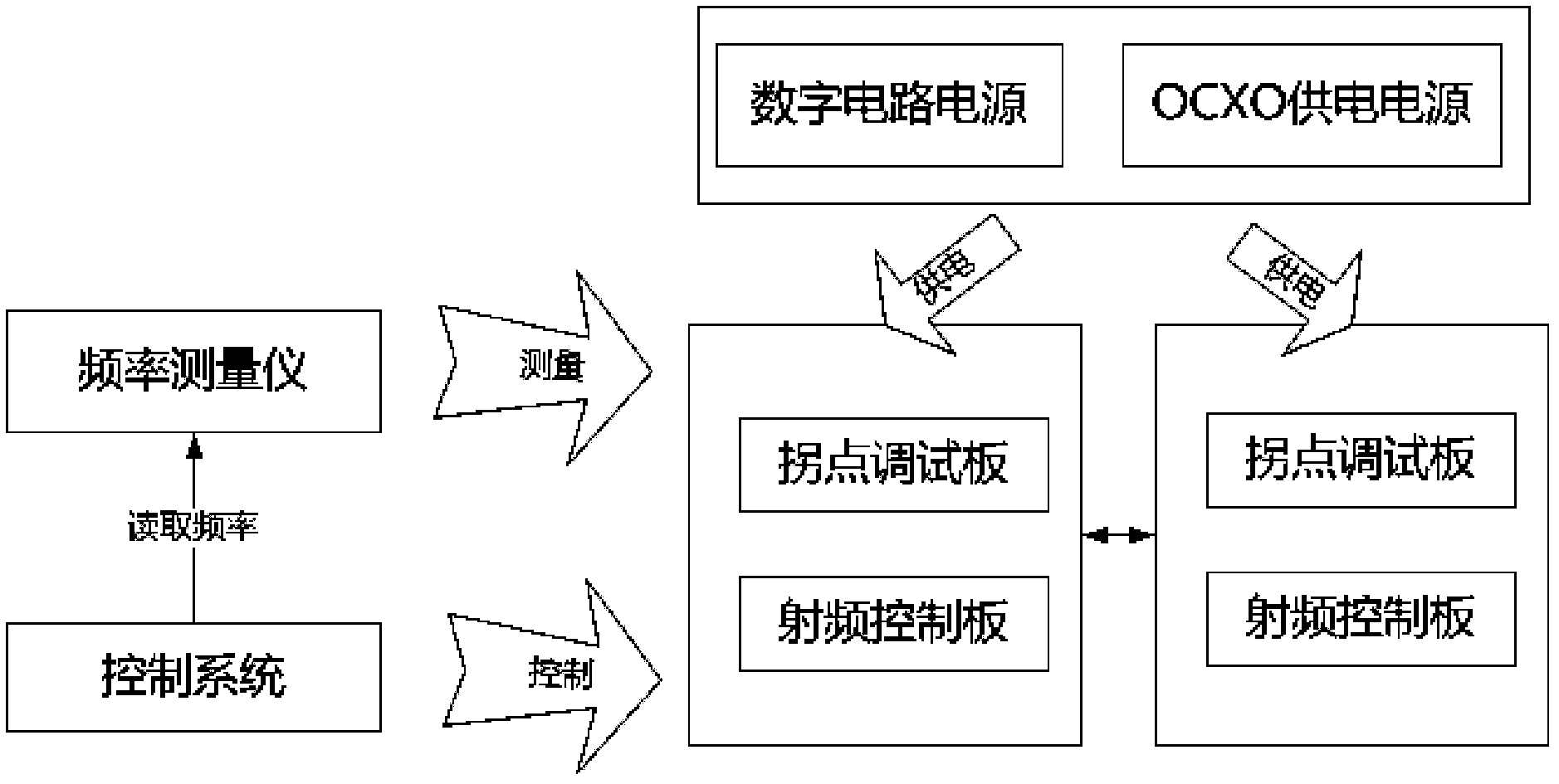

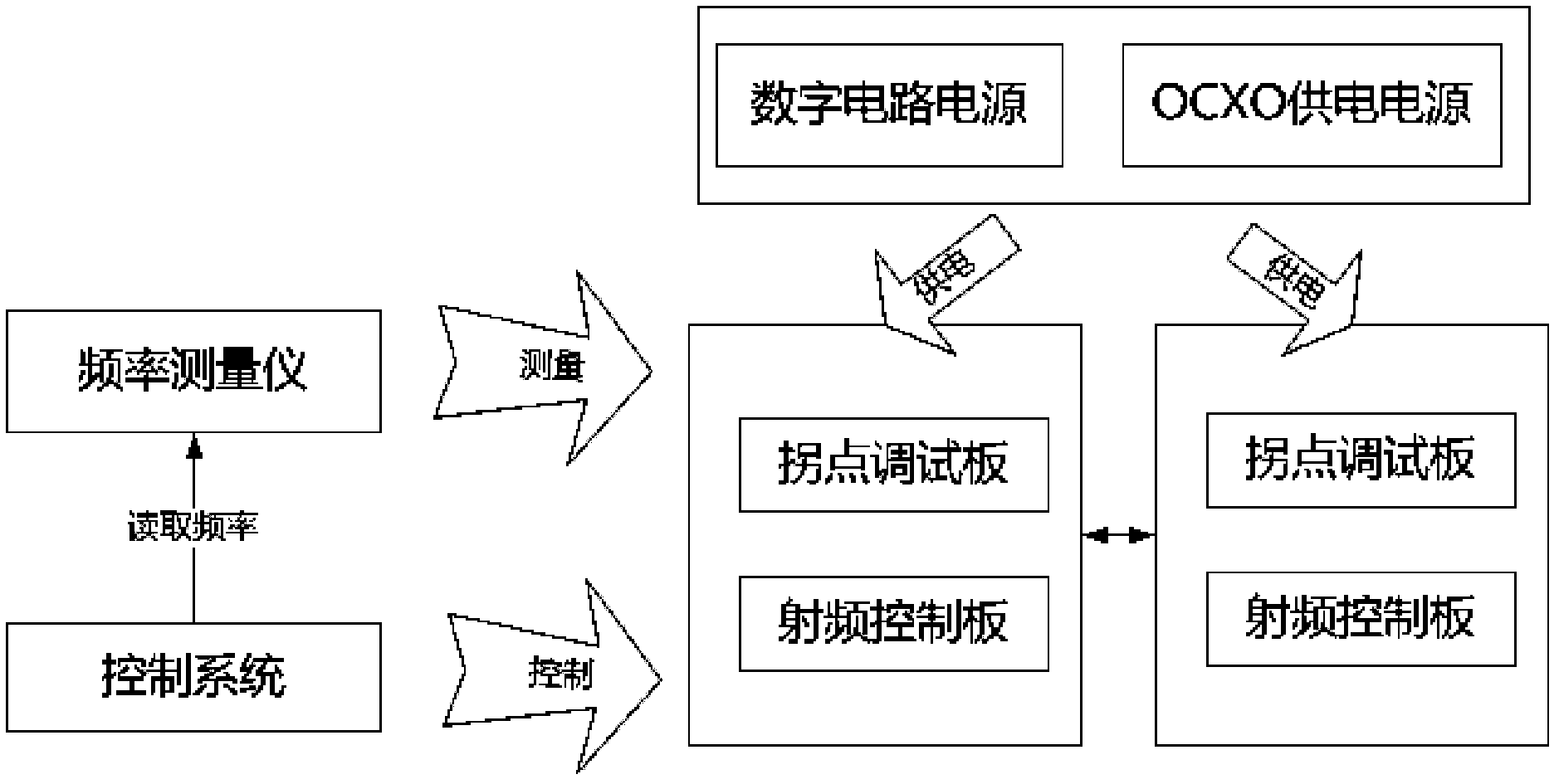

[0021] Such as figure 1 As shown, a complete set of automatic inflection point debugging equipment includes a debugging stand, a frequency measuring instrument and a control computer. The debugging rack is the place where the inflection point debugging is carried out, and a copper strip is installed on the back to transmit power. The debugging rack is a layered iron shelf, which is used to install the OCXO inflection point debugging board and the RF control board. The debugging rack is divided into 6 floors, and the debugging boards are installed on the lower five floors. Two inflection point debugging boards and one RF control board are installed on each floor. Each inflection point debugging board contains 8 inflection point debugging sockets. The crystal oscillator to be tested is plugged into the Inflection point debugging socket, so each layer can debug 16 OCXOs at

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap