High-colour fastness spinning acrylic fabric

A high color fastness, acrylic technology, applied in textile materials and application fields, can solve the problems of poor color fastness, washing fastness and light fastness, poor dyeing uniformity, difficult processing, etc. Good combustion effect, uniform color difference and good brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of high color fastness spinning acrylic fiber fabric, described acrylic fiber fabric is mainly formed by weaving of acrylic fiber yarn, and its specific preparation method is:

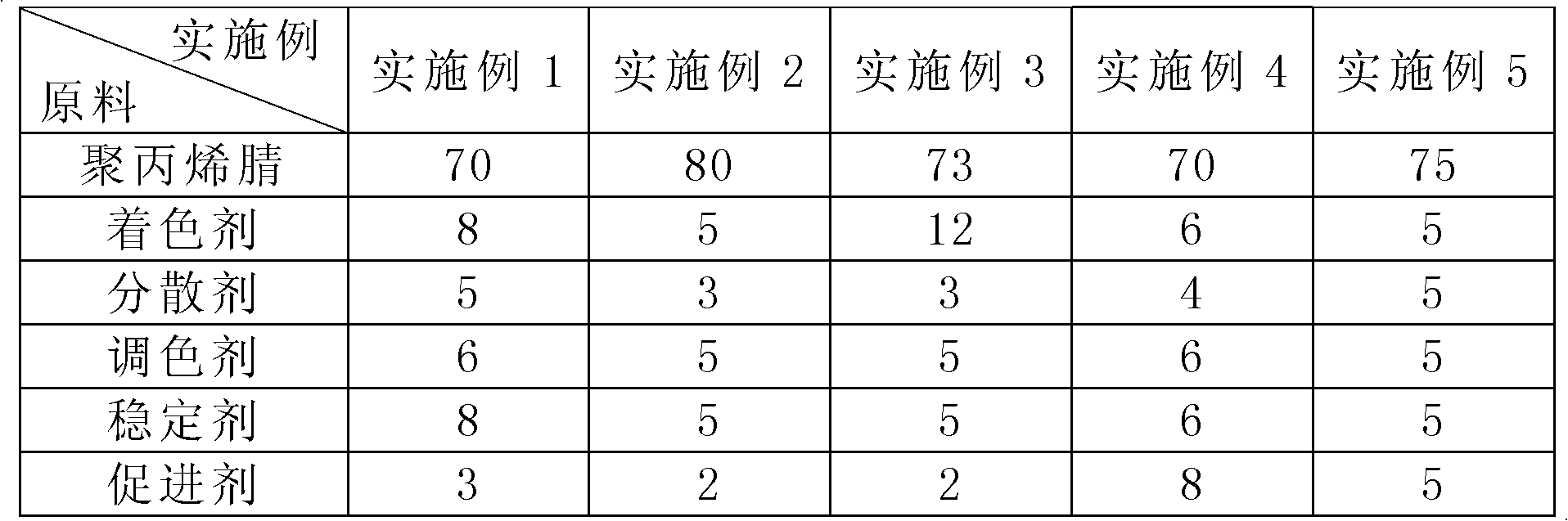

[0046] A, select polyacrylonitrile, colorant, dispersant, toner, stabilizer, flame retardant, antioxidant and accelerator according to the weight ratio of each raw material in the embodiment 1 of table 1, after mixing evenly then, pass The feeding port of the screw extruder is added to the extruder, and the extrusion temperature of each section of the extruder is set to 120°C, 140°C, 180°C, 220°C, and 190°C, so that the mixture becomes a melt, and then passes through the screw Extrude, extrude and granulate to make the corresponding color masterbatch;

[0047] B. Processing and spinning the above-mentioned color masterbatch through a spinning machine, the spinning temperature is set at 175°C to 185°C, and the synthetic fibers obtained after spinning are deformed to form acrylic yarns; the de

Embodiment 2-10

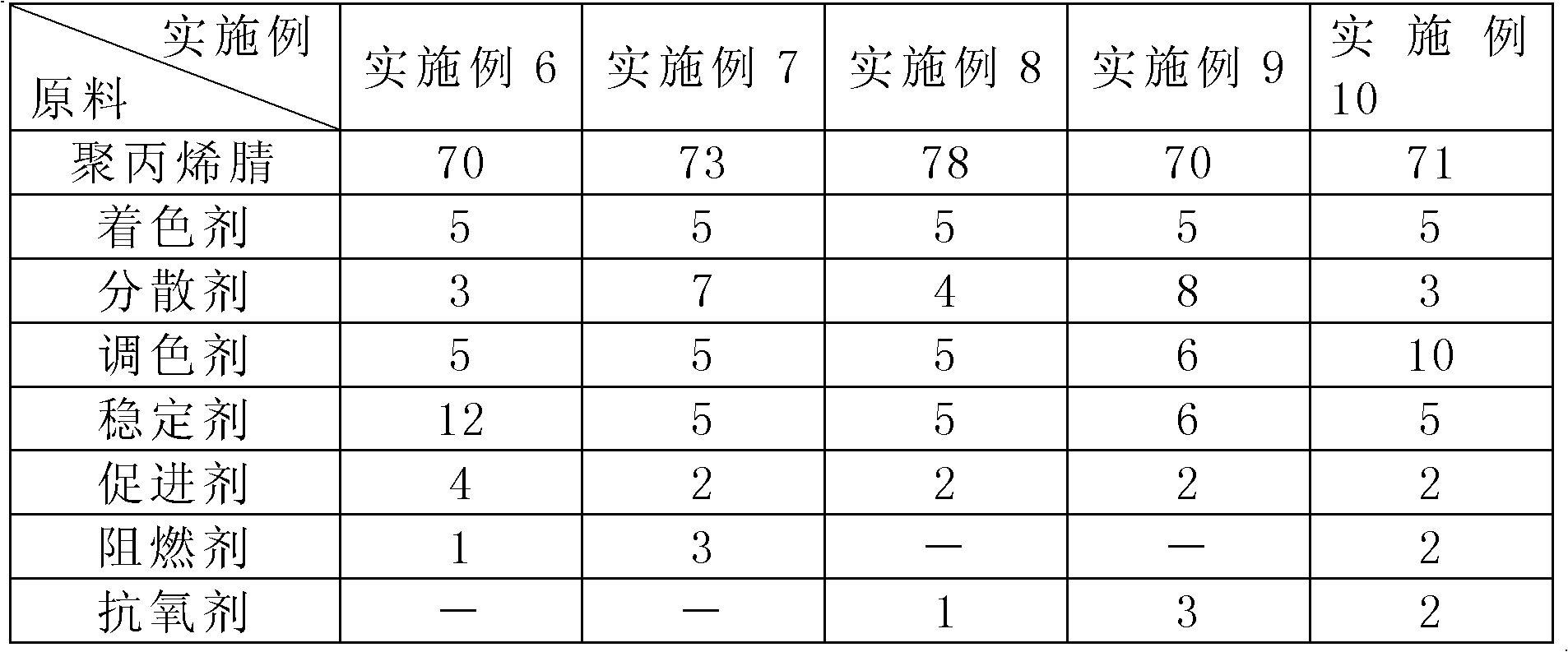

[0050] A kind of high color fastness spun acrylic fiber fabric, described acrylic fiber fabric is mainly formed by weaving of acrylic fiber yarn, the specific preparation method is consistent with the method described in embodiment 1, the difference is that wherein the weight ratio of raw materials used is according to the table 1 and the concrete weight ratio of embodiment 2-10 corresponding embodiment in table 2 is selected.

[0051] The acrylic fabrics prepared in the above examples were randomly selected, and their color fastness was detected and analyzed according to national standards.

[0052] Select the acrylic fabric obtained in Example 1 to detect and analyze, and the analysis results are: its color fastness to washing reaches 4 to 5 grades, the color fastness to perspiration reaches 4 to 5 grades, and the color fastness to light and sunlight reaches 8 grades;

[0053] The acrylic fabric obtained in Example 3 is selected for detection and analysis, and the analysis resu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap