High-color-fastness water-based pigment black as well as preparation method and application thereof

A high color fastness, water-based pigment technology, applied in the direction of pigment slurry, etc., can solve the problem of not strengthening the fastness of coating or pigment particles to textiles, unstable coating or pigment ink system, and unfavorable inkjet printing performance and other problems, to achieve excellent physical coating, excellent color fastness, and improve the effect of combination fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

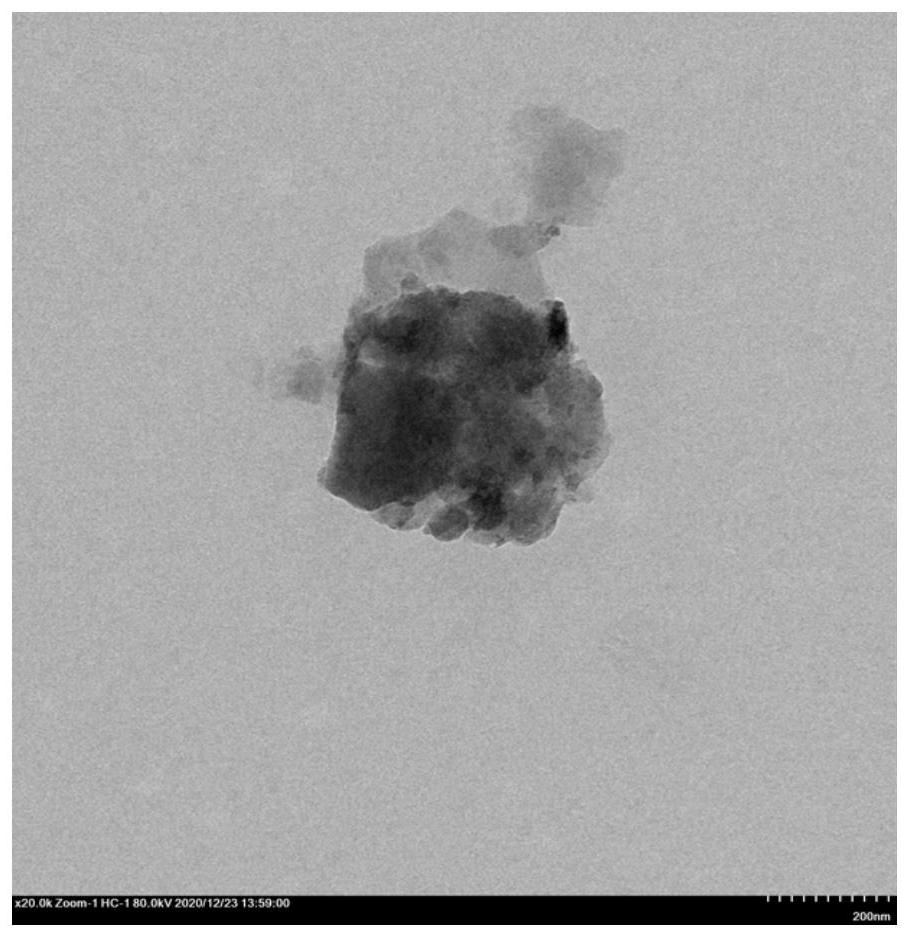

[0023] Add 15.0 grams of Pigment Black 32, 1.1 grams of Oleth OV-20, 1.1 grams of Glyceryl Polyether G-26 and 82.8 grams of water into a planetary ball mill, and use zirconia beads to grind continuously for 4.0 hours to obtain a particle size of not high Pigment Black 32 liquid at 160 nm; add 20.0 g of binder S0501 and 10.0 g of crosslinking agent JS to the above pigment liquid, and continue grinding for 2 hours to obtain water-based Pigment Black 32 with a particle size not higher than 100 nm.

Embodiment 2

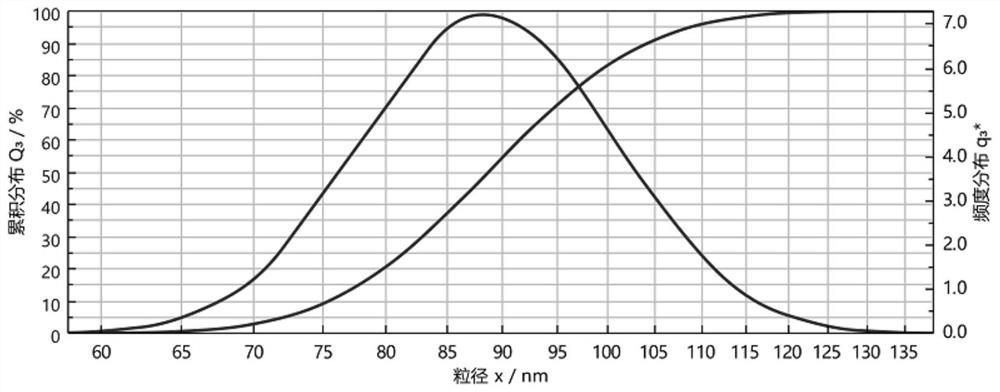

[0025] Add 15.0 grams of Pigment Black 32, 1.1 grams of Oleth OV-20, 1.1 grams of Glyceryl Polyether G-18 and 82.8 grams of water into a planetary ball mill, and use zirconia beads to grind continuously for 4.0 hours to obtain a particle size of not high Pigment Black 32 solution with a particle size of 160nm; add 20.0g of binder S0501 and 10.0g of crosslinker JS to the above pigment solution, and continue grinding for 1.5 hours to obtain water-based Pigment Black 32 with a particle size of 96.65nm, not higher than 100nm.

Embodiment 3

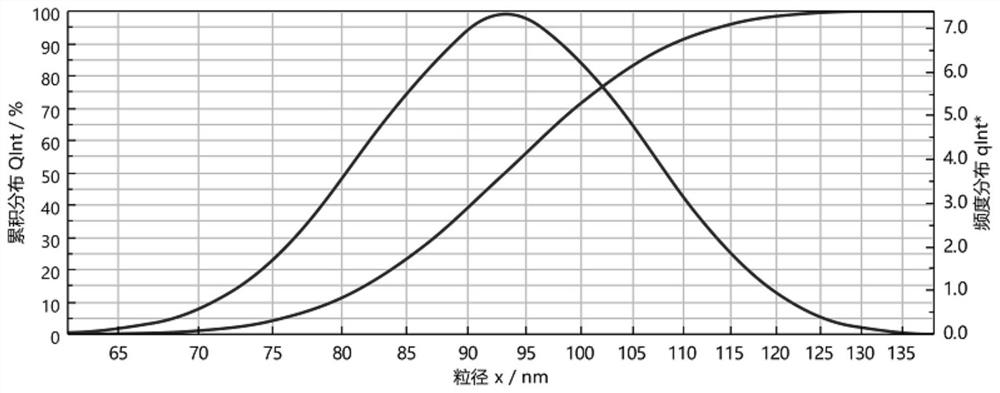

[0027] Add 15.0 grams of Pigment Black 32, 1.1 grams of Oleth OV-24, 1.1 grams of Glyceryl Polyether G-20 and 82.8 grams of water into a planetary ball mill, and use zirconia beads to grind continuously for 3.5 hours to obtain a particle size not high Pigment Black 32 solution at 160nm; add 20.0g of binder S0501 and 10.0g of crosslinking agent JS to the above pigment solution, and continue grinding for 2 hours to obtain water-based Pigment Black 32 with a particle size of 98.78nm, not higher than 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap