Wheel spoke plane difference inspection device

A technology of plane difference and spokes, applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve the problems of troublesome detection process, limited number of detection points, and inability to read directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

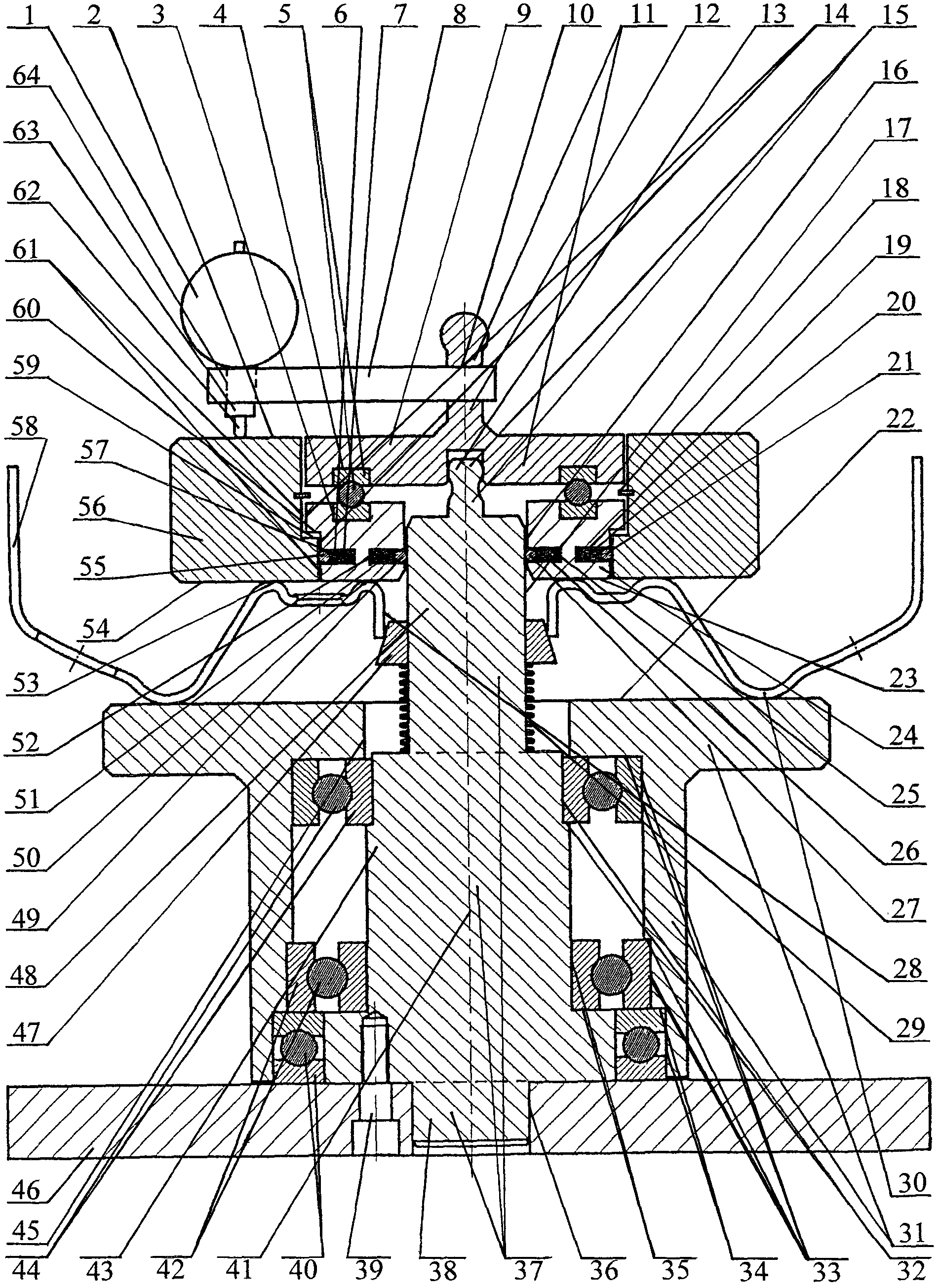

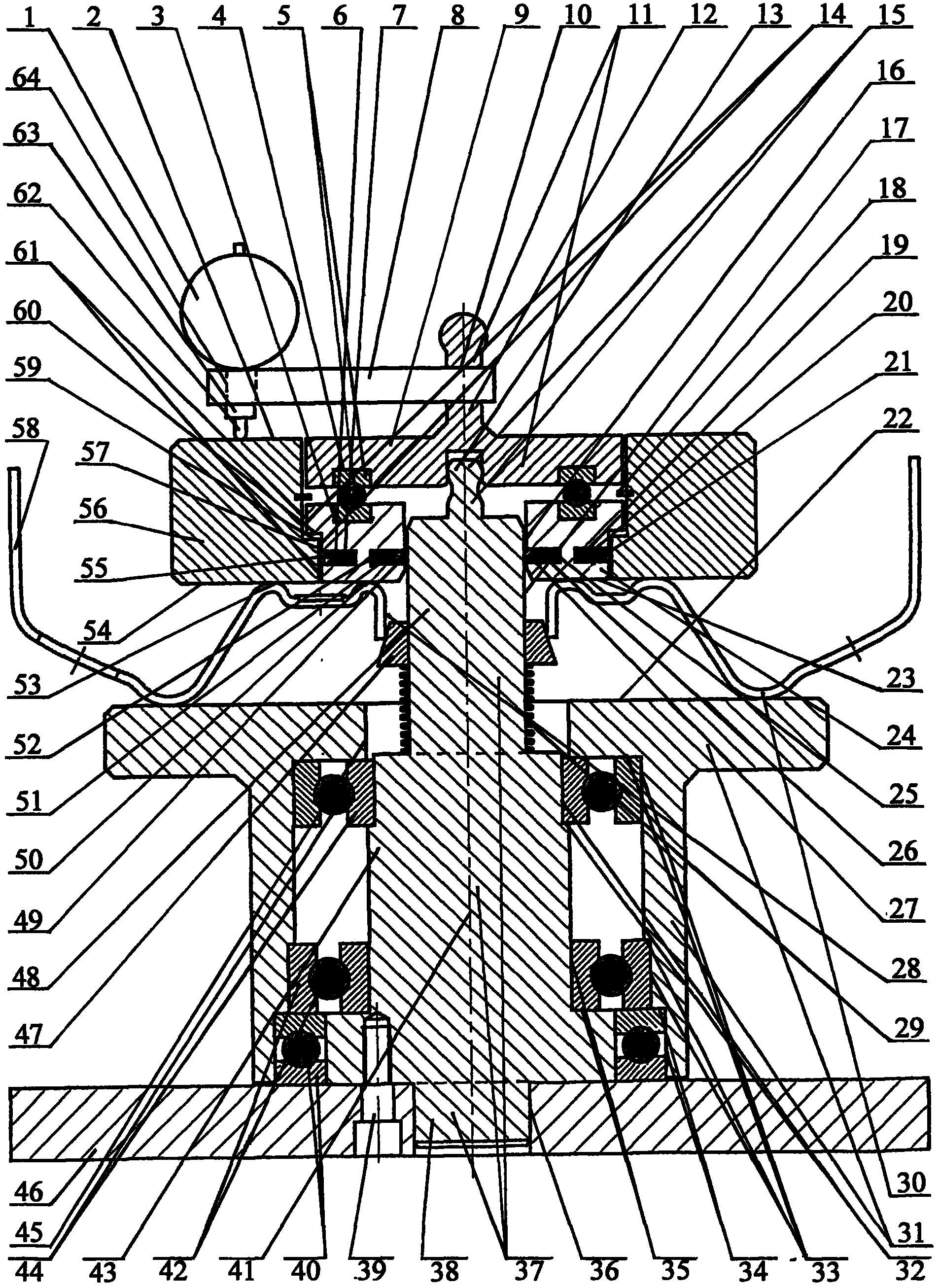

[0009] Wheel spoke plane difference inspection tool, as shown in the figure:

[0010] The whole mainly includes a center shaft assembly provided with a center shaft 37, a center hole guide cone 47 for positioning the spokes 58 as shown in the figure, and a height adjustment spring 29, and a standard plane 22 and shaft for supporting the spokes 58. The supporting assembly of the hole 45 is provided with a dial indicator 1, an inner circle plane measuring plate 24, an outer inner circle plane measuring plate 56, and a plane difference measuring component of the spoke plane difference data measuring plane 2. In this way, by setting the standard plane 22 on the support assembly, setting the center hole guide cone 47 and the height adjustment spring 29 on the center shaft assembly, the wheel spokes 58 with different center holes 28 inner diameters can be correc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap