Clamping caster

A snap-fit, caster technology, applied in the direction of casters, wheels, transportation and packaging, etc., can solve the problems of low concentricity of two spokes, low production efficiency, short practical life, etc., to save manpower, improve efficiency, and reliable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

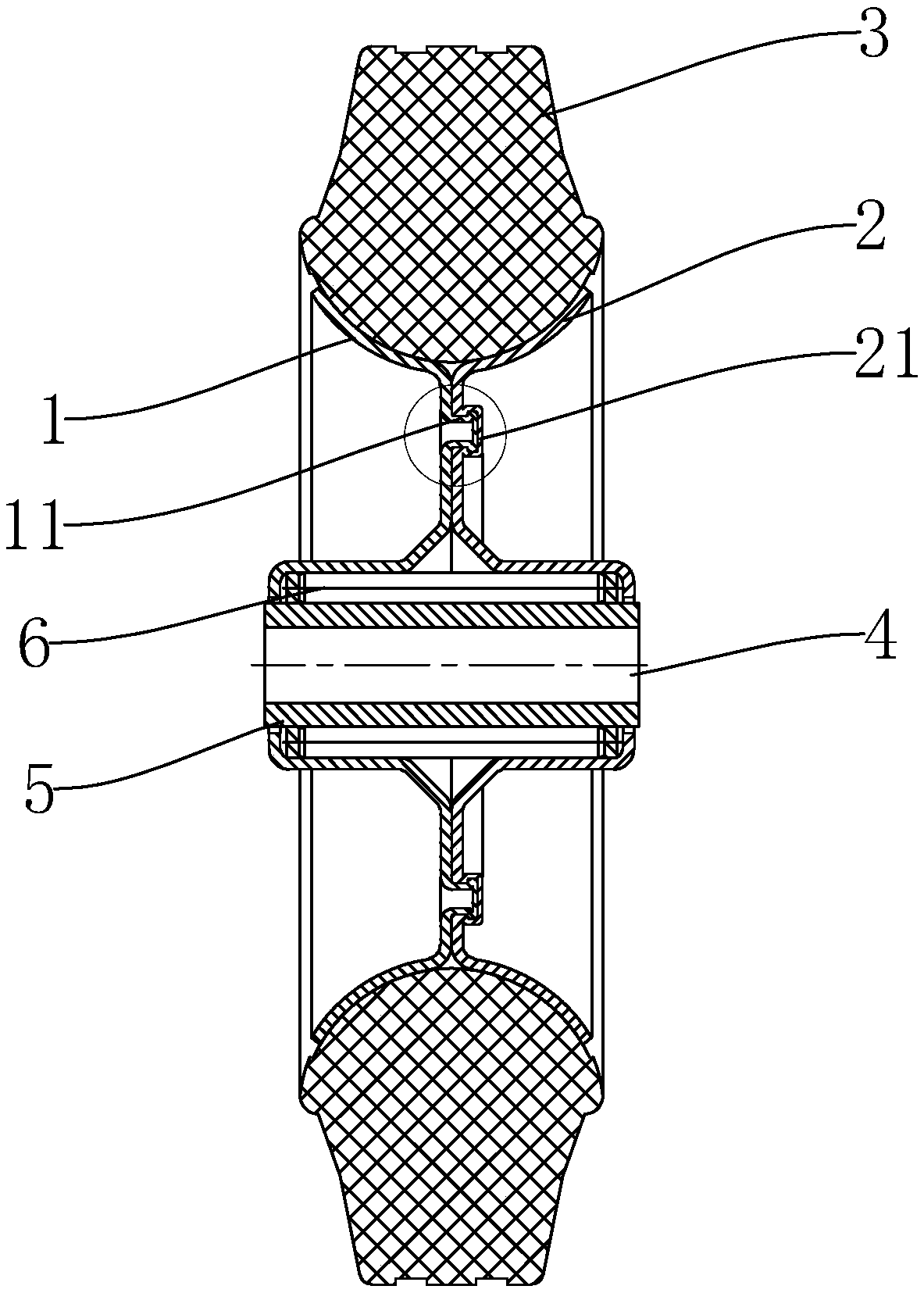

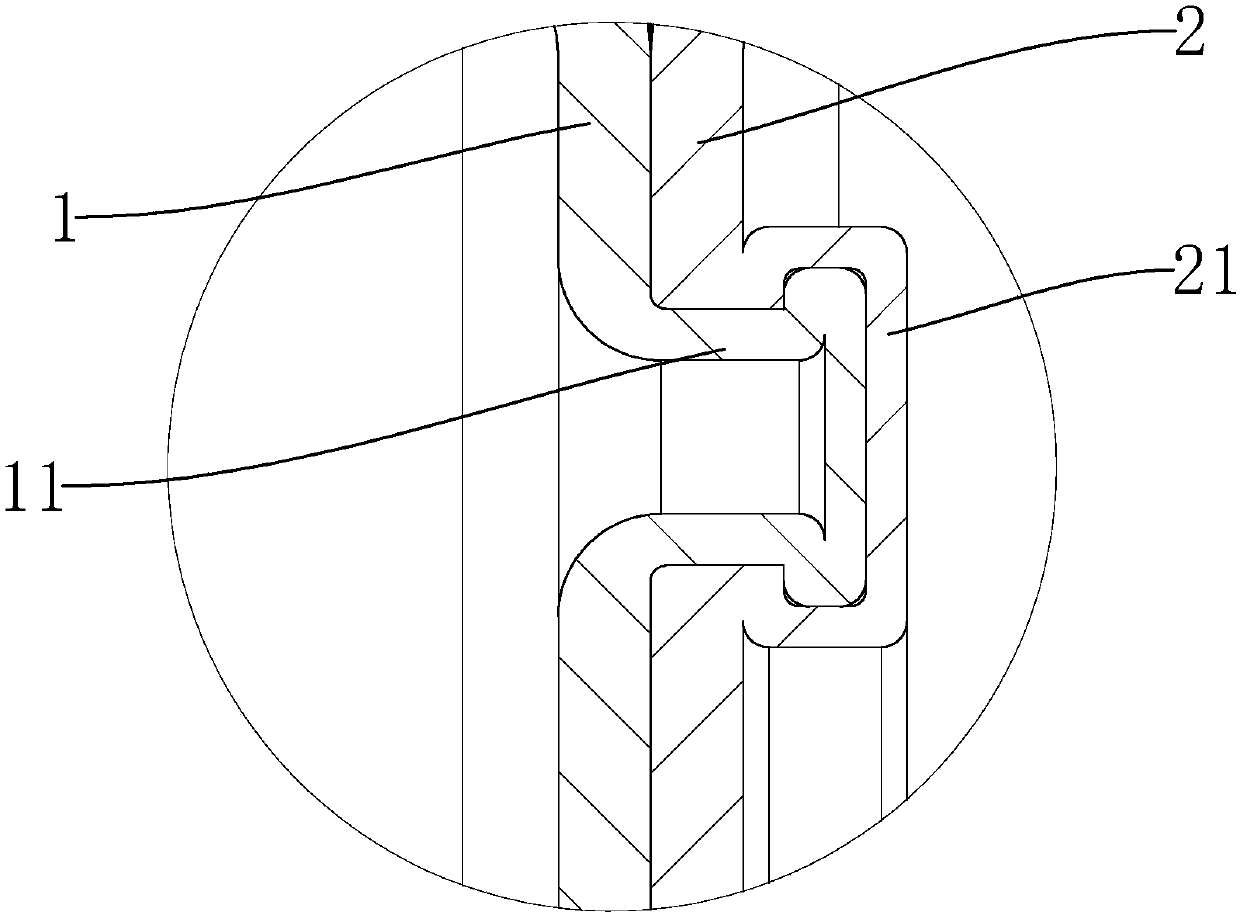

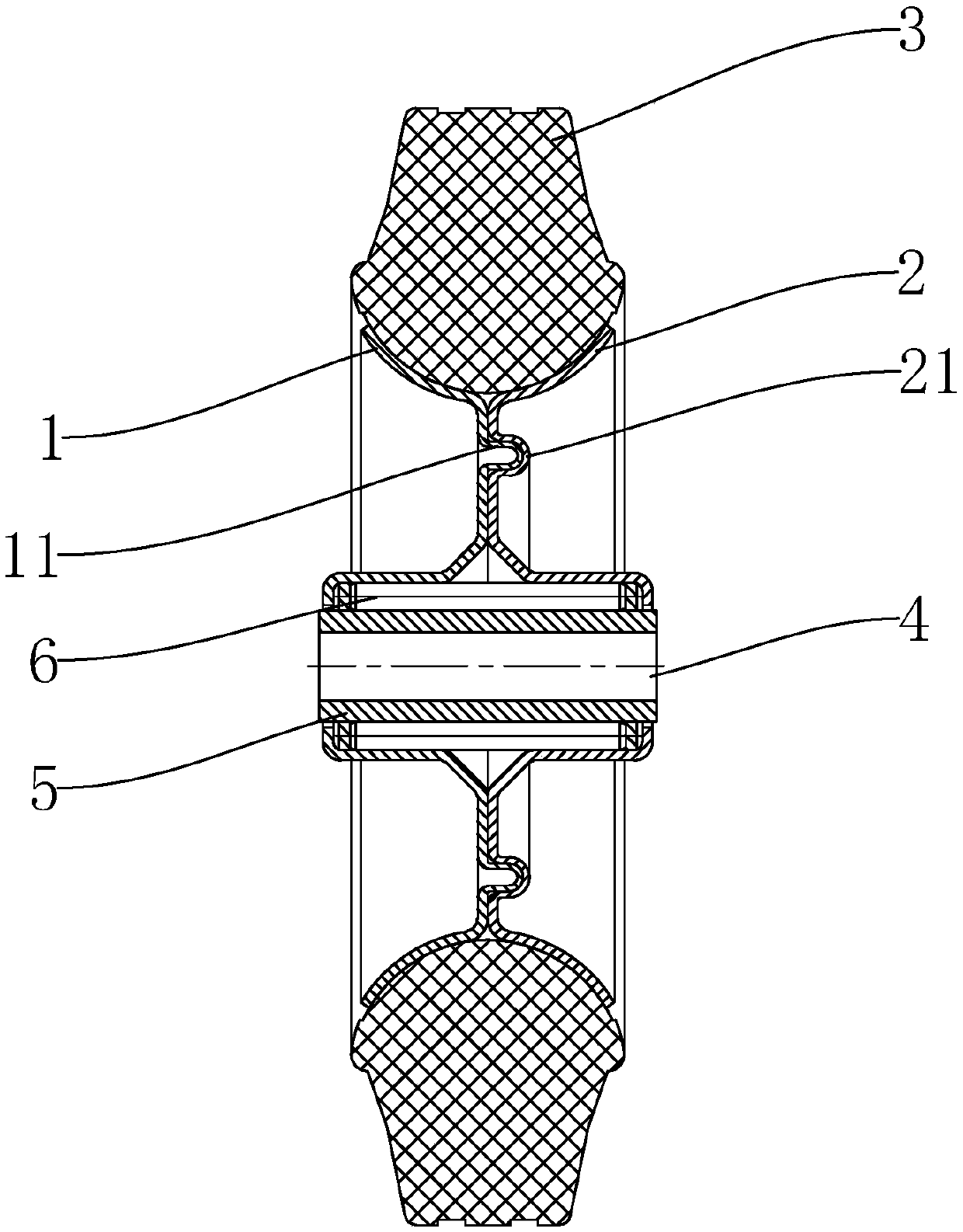

[0019] refer to Figure 1 to Figure 5 , Figure 1 to Figure 5 It is a specific structural schematic diagram of an embodiment of the present invention. As shown in the figure, a clip-on caster includes a first spoke 1, a second spoke 2 and an outer wheel 3, and the first spoke 1 and the second spoke 2 The shape is bowl-shaped, the first spoke 1 and the second spoke 2 are combined with their backs facing outward, and the first spoke 1 and the second spoke 2 are combined to form a hub through a buckle structure. In the present invention , the buckle structure includes an annular boss 11 arranged on the first spoke 1 and an annular groove 21 matched with the annular boss 11 arranged on the second spoke 2, of course, in other embodiments , the buckle structure may include an annular groove 21 arranged on the first spoke 1 and an annular boss 11 arranged on the second spoke 2 and matched with the annular groove 21, during the production process, the After the annular boss 11 and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap