Large tire assembling process for snow bike

A bicycle and large-format technology, which is applied to wheel assembly and disassembly equipment, wheel fixing devices, wheels, etc., can solve the problems of heavy tire weight, inconvenient riding, and inability to reduce tire weight, so as to improve service life and reduce tire weight. effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0017] As shown in the figure, the present invention includes the following steps,

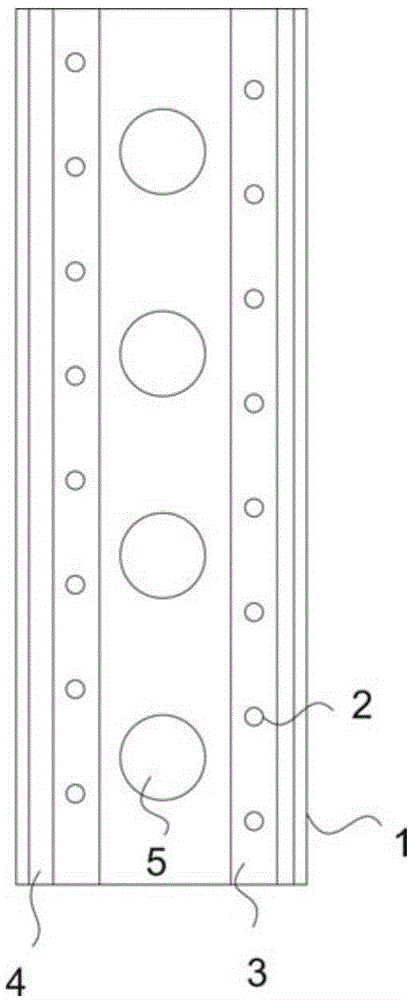

[0018] a. Evenly process multiple hollow holes around the rim;

[0019] b. Connect one end of the spoke to the hub, and the other end to pass through the spoke holes on both sides of the rim;

[0020] c. Cover the positions of the spoke holes on both sides with the fiberglass tape around the rim;

[0021] d. Cover the hollow hole with the pad tape around the rim, and extend the width of the pad tape to the glass fiber protective tape on both sides, so that the glass fiber protective tape does not contact the inner tube;

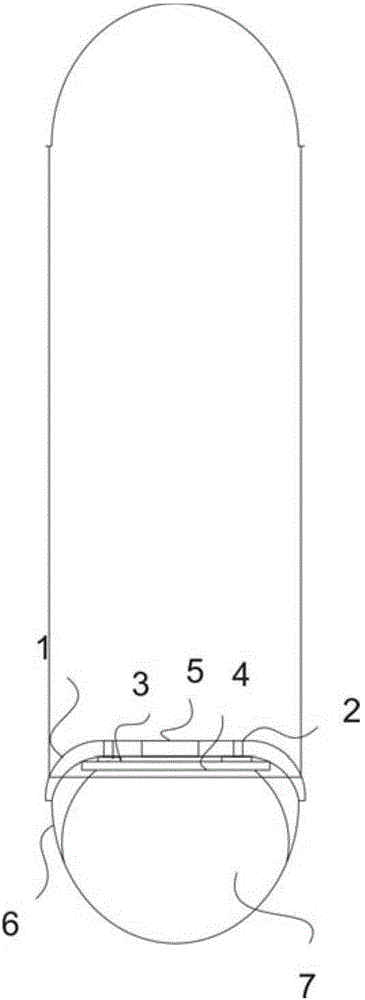

[0022] e. Install the inner tube outside the pad and the outer tire outside the inner tube. Since multiple hollow hol

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap