Car door sill device filling gap of stopped layer

A technology of sills and gaps, applied in the field of elevators, can solve problems such as danger, trouble, and small rollers stuck, and achieve the effects of simple structure, convenient installation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

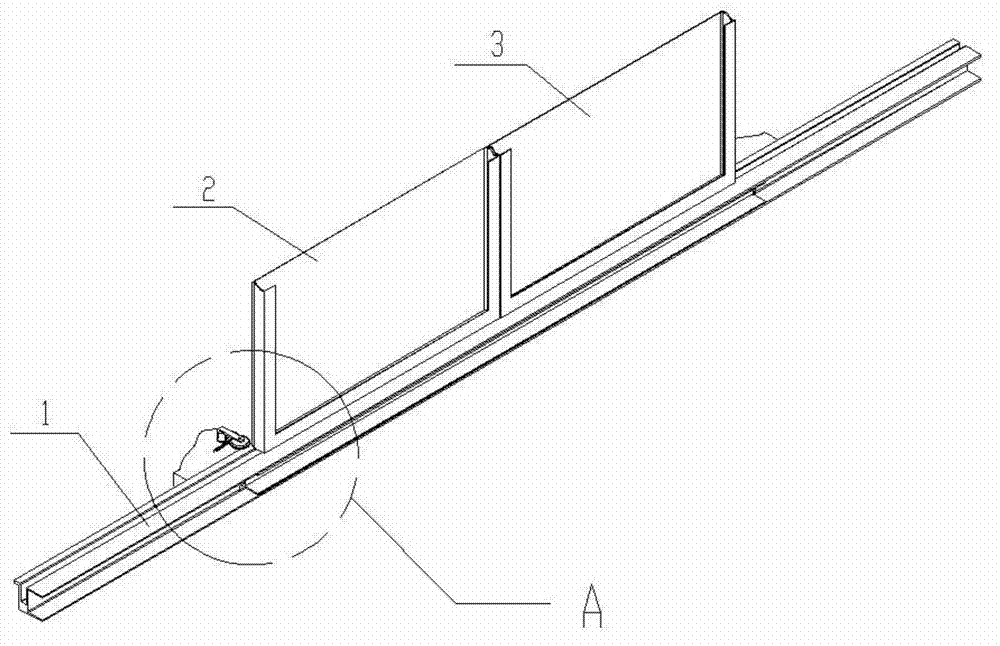

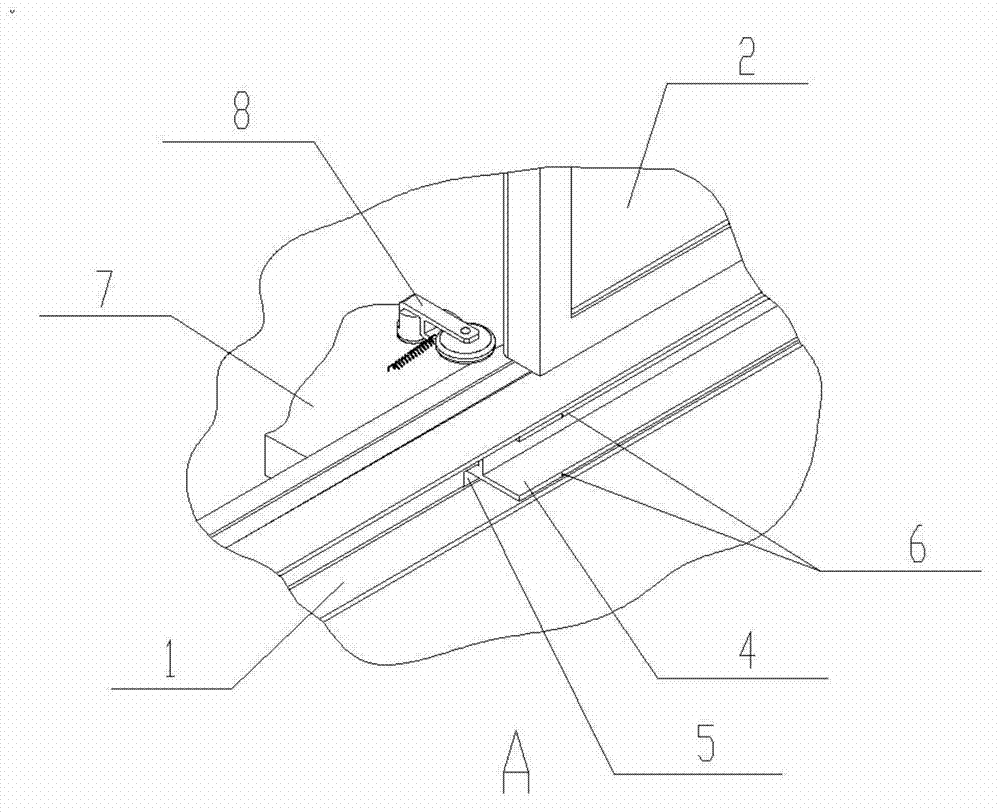

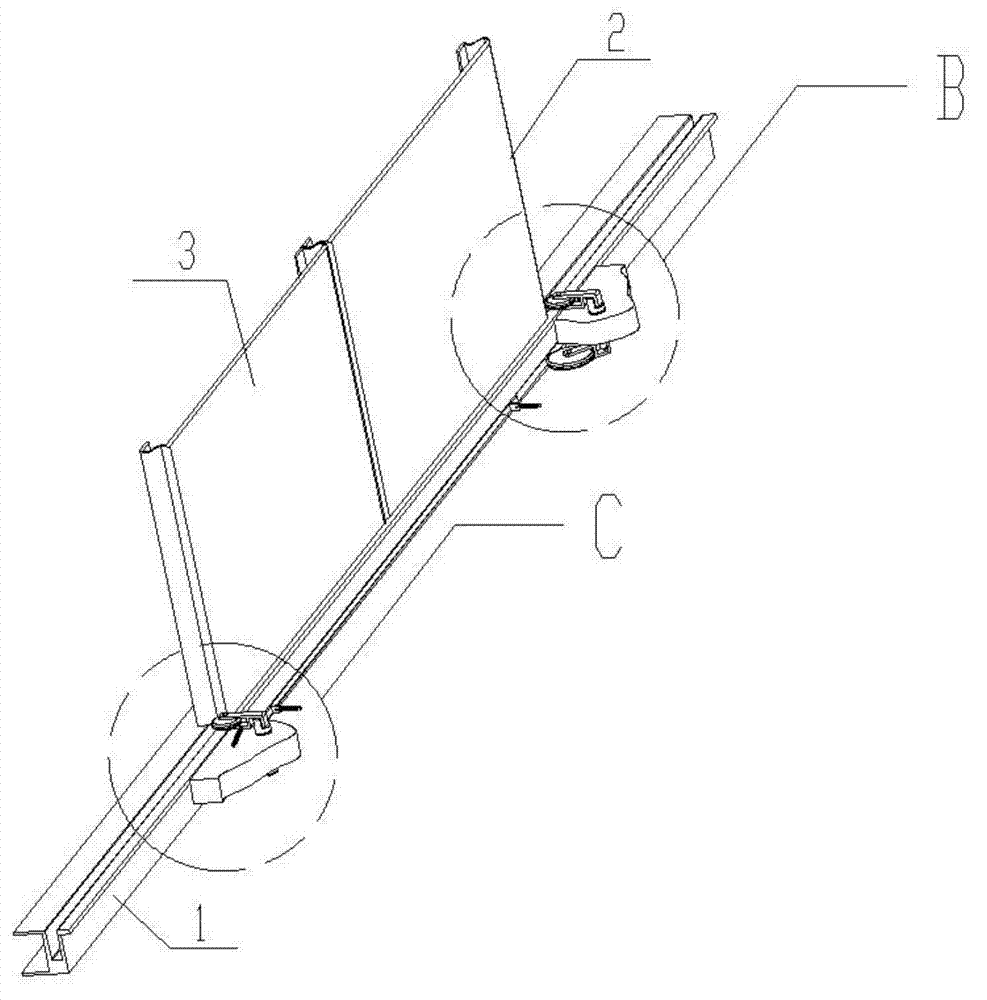

[0033] Such as Figures 1 to 5 As shown, a car door sill device for filling the landing gap according to the present invention includes a car sill 1 with a gap 5, a retractable safety touch panel 4, and a roller assembly that can trigger the expansion and contraction of the safety touch panel 4 8.

[0034] The car side of the safety contact plate is connected with the car floor assembly or the car outer side 7 through a spring 15 .

[0035] Such as Figure 4 , 5 As shown, the roller assembly 8 is composed of two rollers 10, 11, two roller brackets 12, 13, a main shaft 14, a spring 9 and supporting roller shafts and bushings and other accessories.

[0036] The rollers 10 , 11 are mounted on one end of the roller brackets 12 , 13 respectively, and the other ends of the roller brackets 12 , 13 are connected to the end of the main shaft 14 . One end of the spring 9 is connected with the upper roller bracket 12, and the other end is connected with the car bottom assembly or the ou

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap