Positioning turning device

A rotary shaft and rotary disc technology, applied in the field of multi-station processing devices, can solve the problems of high investment cost, large floor space, and adding manipulators, etc., and achieve the effect of small floor space, compact structure, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

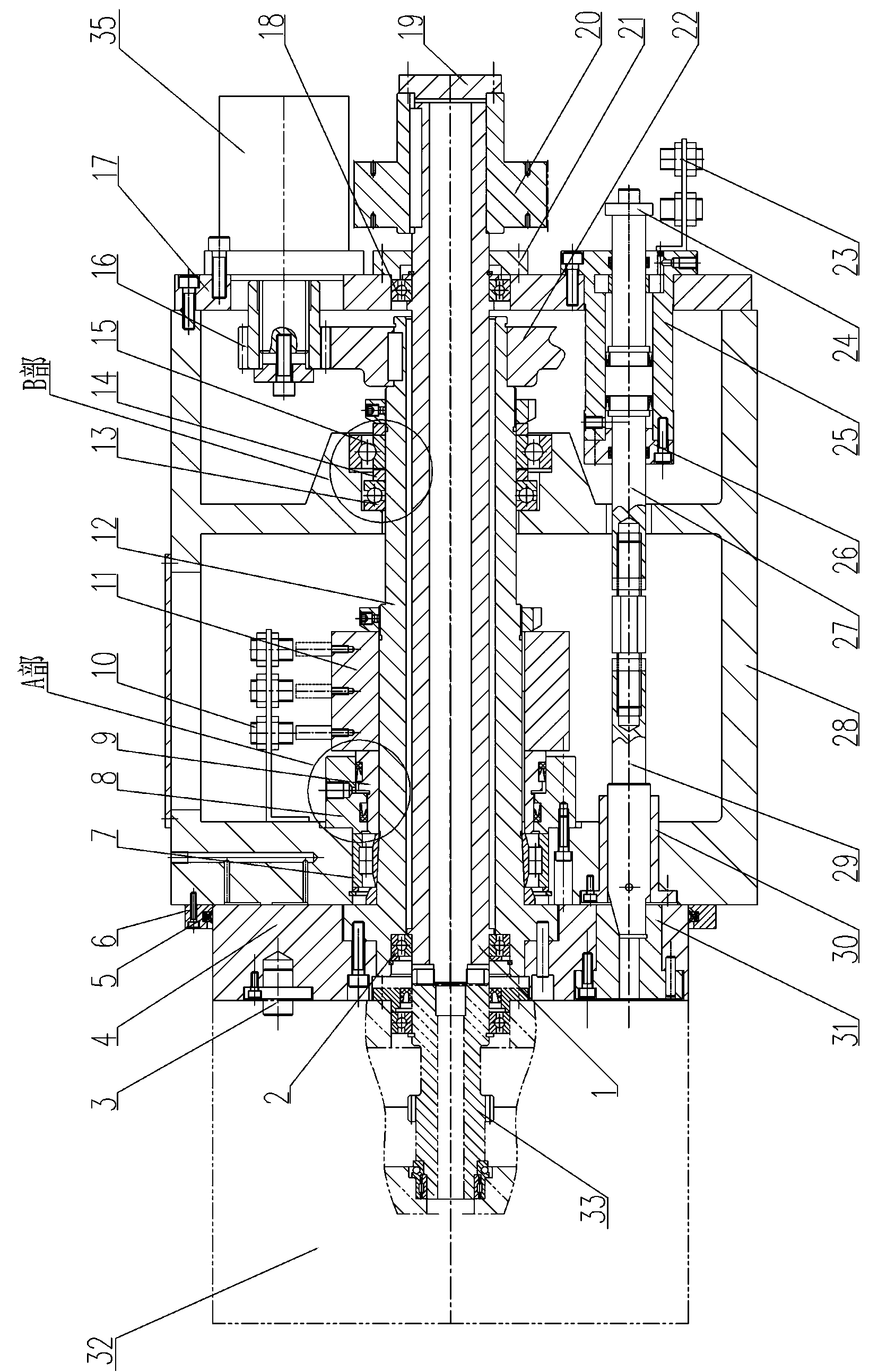

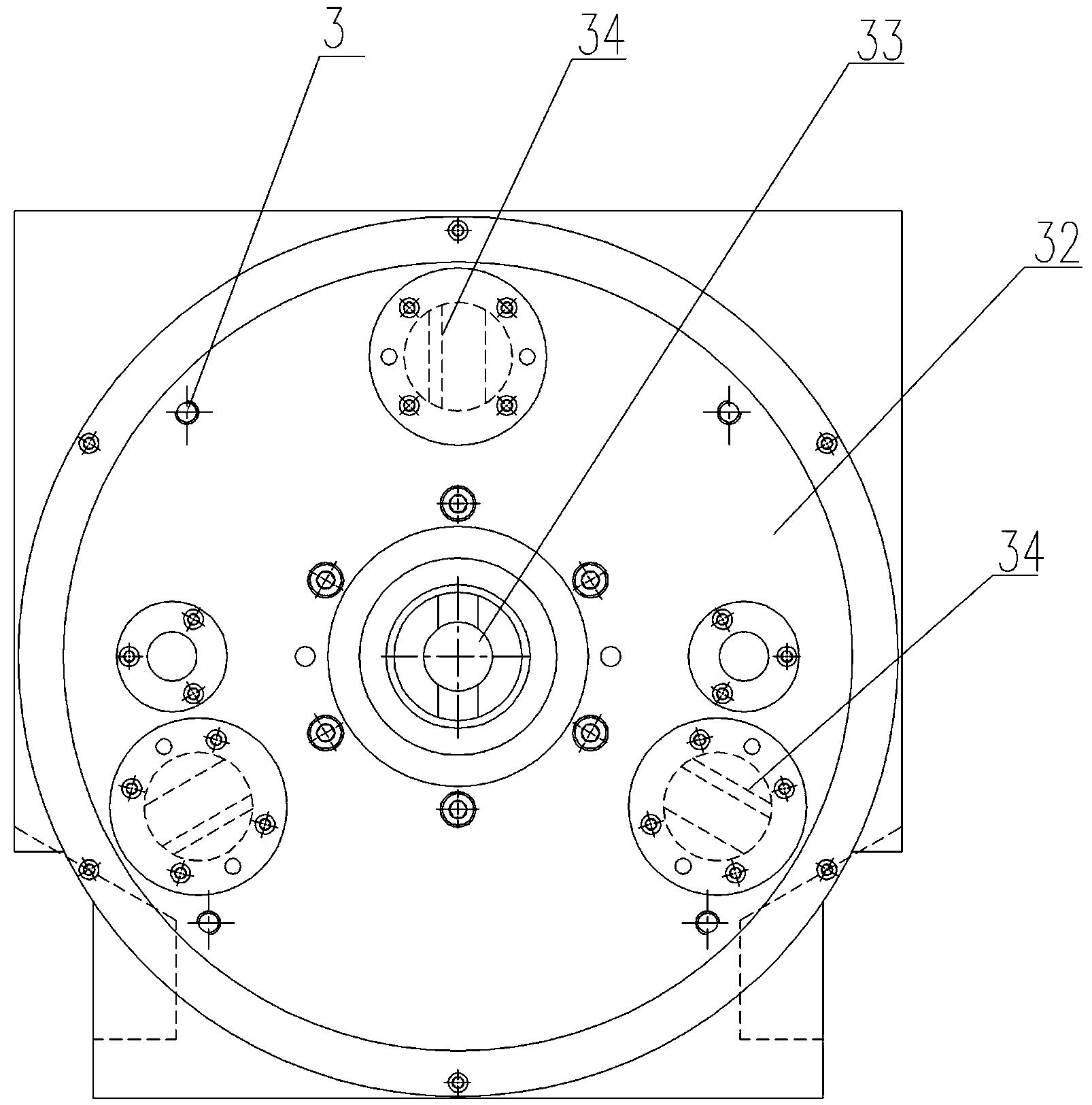

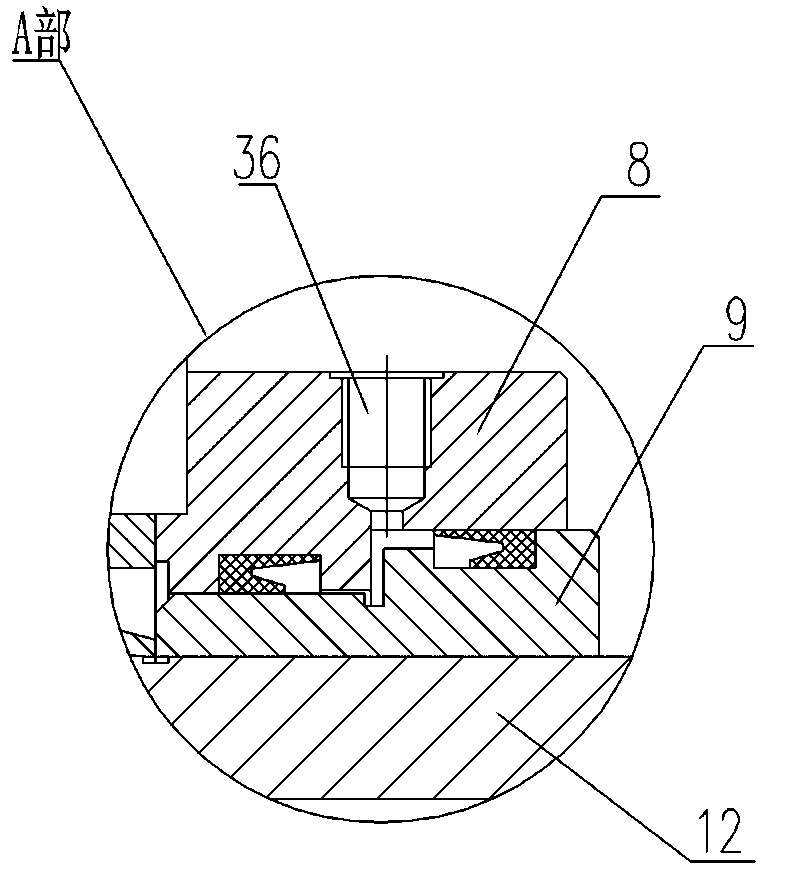

[0017] Embodiment 1: see Figure 1-Figure 4 Positioning rotary device in. The drive shaft 1 is installed on the rotary shaft 12 and the rear cover 17 of the box with two ball bearings 2, 18. The rear end of the drive shaft 1 is equipped with a toothed belt pulley 20 powered by a driving motor, and the front end is connected with the keyway on the rear end surface of the drive shaft of the headstock. Connected to drive the headstock spindle to rotate for processing.

[0018] The back cover 17 of the box body is fixed on the box body 28 with a screw cylindrical pin, and a bolt oil cylinder 25 and a hydraulic motor 35 are installed on it through a positioning bolt. The driving gear 16 is connected with the hydraulic motor 35 by a spline, and the driving gear 16 drives the driven gear 22, the driven gear 22 is connected with the rotary shaft 12 with a key, thereby driving the rotary shaft 12 to rotate, and the rotary disc 4 is connected and fixed with the rotary shaft 12 with screws

Embodiment 2

[0021] Embodiment 2: The accompanying drawings are not drawn, and the content is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that six spindles are evenly distributed on the end surface of the headstock, which is suitable for parts that need to be processed six times. When processing a station, the positioning rotary device drives the spindle box to rotate 60 degrees, and the latch mechanism is inserted into the positioning sleeve to realize positioning.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap