Recovery method of alkyl-halide fire extinguishing agent in fire extinguishing bottle for aviation

A fire extinguishing agent and fire extinguishing bottle technology, which is applied in the recycling and reuse of haloalkane 1301 and 1211 fire extinguishing agents, and the recovery of haloalkane fire extinguishing agents in aviation fire extinguishing bottles. It can solve the problems of storage tank pressure increase, waste, pollution, etc., and achieve protection Effects on the environment, waste reduction, and improvement in recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

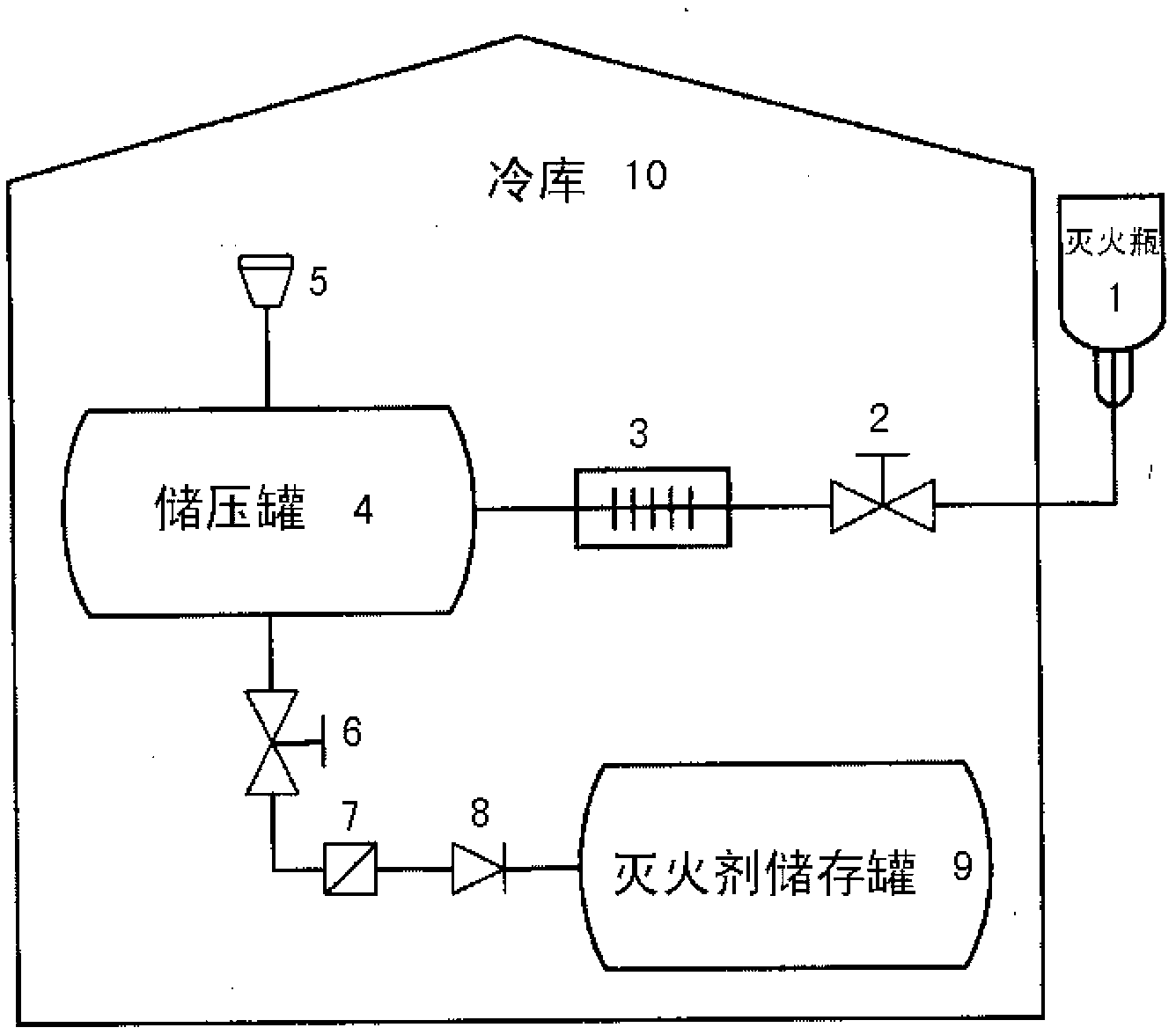

[0011] The present invention proposes a method for recovering the halogenated alkane fire extinguishing agent in an aviation fire extinguishing bottle, which is described below with reference to the accompanying drawings.

[0012] First, establish a fire extinguishing agent recovery system that simultaneously reduces the temperature and raises the pressure to liquefy the fire extinguishing agent; according to actual needs, set the cold storage temperature to -40°C and select the pressure storage tank volume to 35L;

[0013] figure 1 Shown is a schematic diagram of the composition of the fire extinguishing agent recovery system. In the figure, a pressure storage tank 4 with a volume of 35L is placed in a small cold storage or freezer 10, and the temperature of the cold storage is set to -40°C. The pressure storage tank is provided with an inlet, an outlet and a pressure relief port; the inlet of the pressure storage tank is connected to the fire extinguishing bottle 1 to be recovered

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap