Solidification process device

A technology for curing and processing objects, applied to magnetic recording heads, magnetic heads using thin films, etc., can solve problems such as difficult temperature control, adhesive failure, and magnetic head damage, and achieve the effect of easy temperature control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

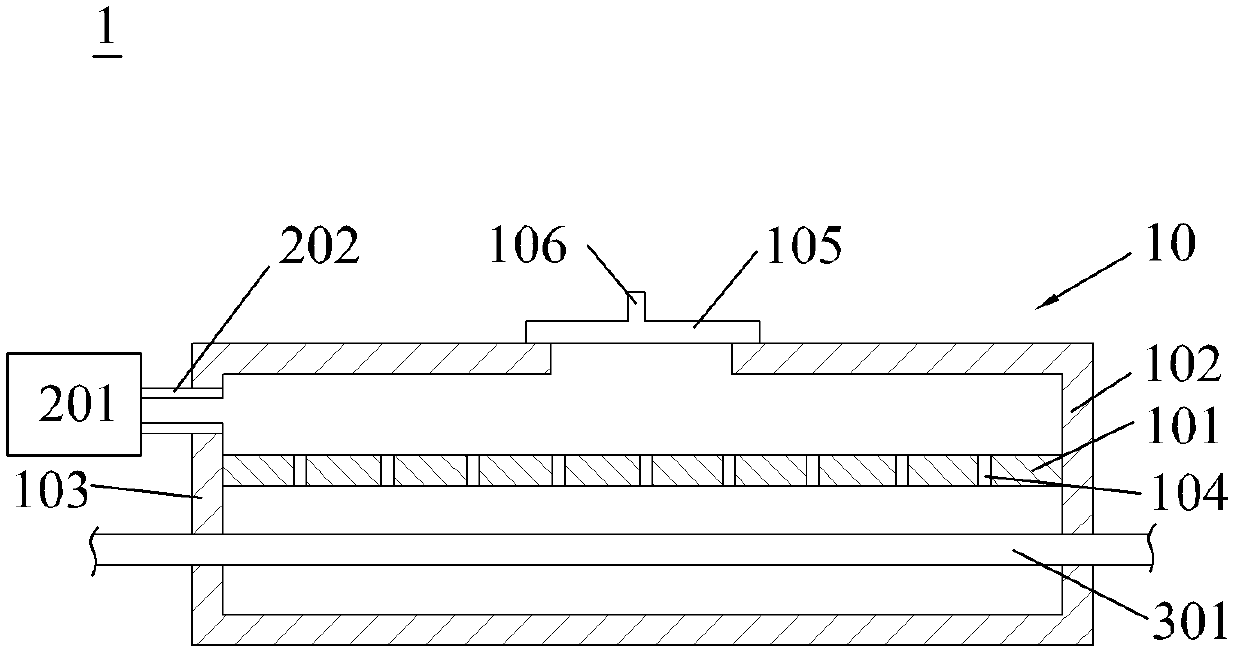

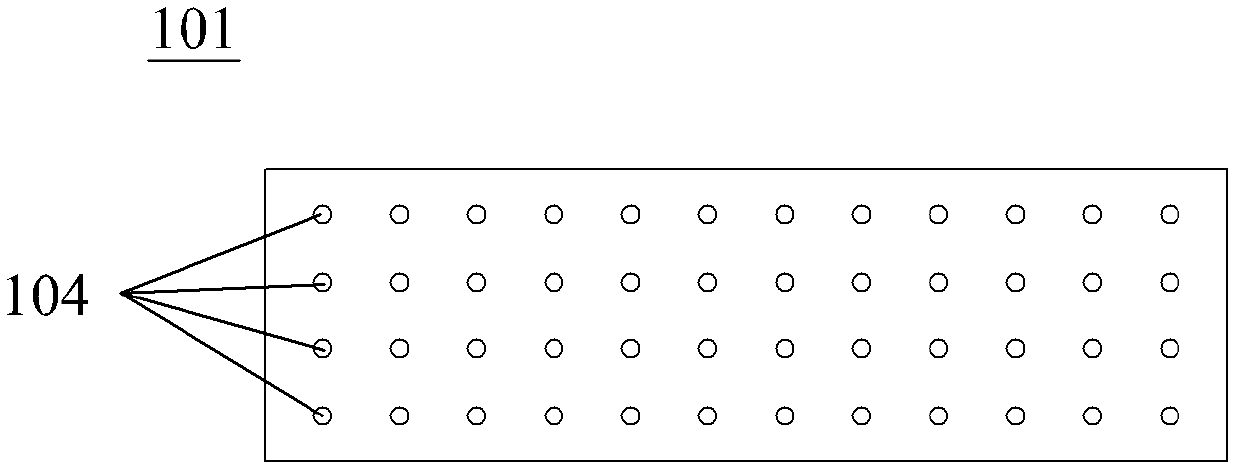

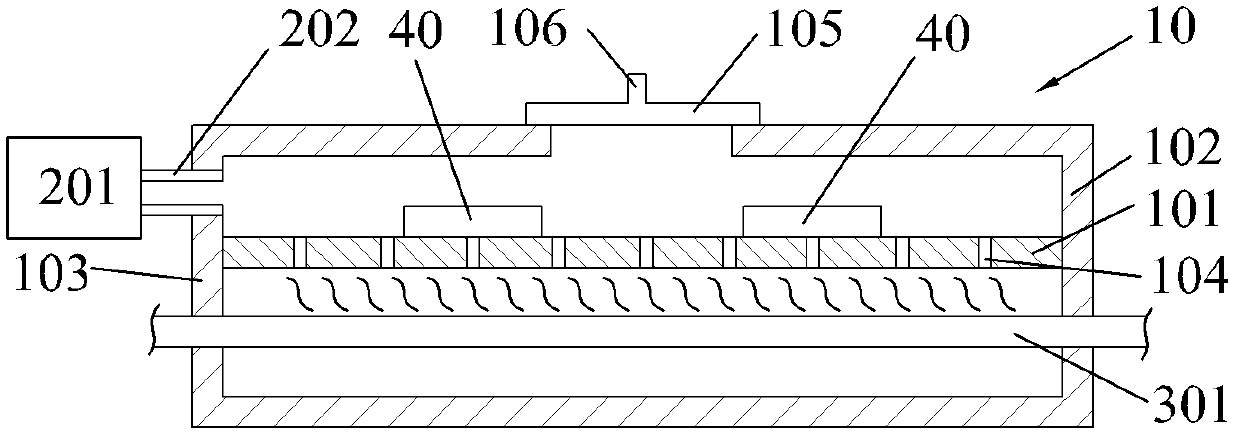

[0021] Several different preferred embodiments of the present invention will now be described with reference to the accompanying drawings, wherein like reference numerals in different drawings represent like parts. As mentioned above, the essence of the present invention lies in a curing treatment device, which heats up the air pressure box through the hot water pipe of the heat generating device, and simultaneously pressurizes the air pressure box through the air pressure applying device, so that the air pressure box reaches a predetermined temperature, thereby Make the object to be treated in the air box achieve the purpose of curing and drying.

[0022] refer to figure 1 , the curing treatment device 1 of the present invention includes an air pressure box 10 , an air pressure applying device 20 and a heat generating device 30 respectively connected to the air pressure box 10 . Specifically, the object to be treated is placed in the air box 10 , the air pressure applying devic

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap