Device for online measuring dynamic performance of ultra-precision hydrostatic spindle and method for measuring dynamic performance of hydrostatic spindle by using same

A technology of static pressure spindle and dynamic performance, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc. It can solve the problems that the ultra-precision static pressure spindle cannot be realized, and the installation error of the measurement reference is difficult to solve. The effect of eliminating measurement error and eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

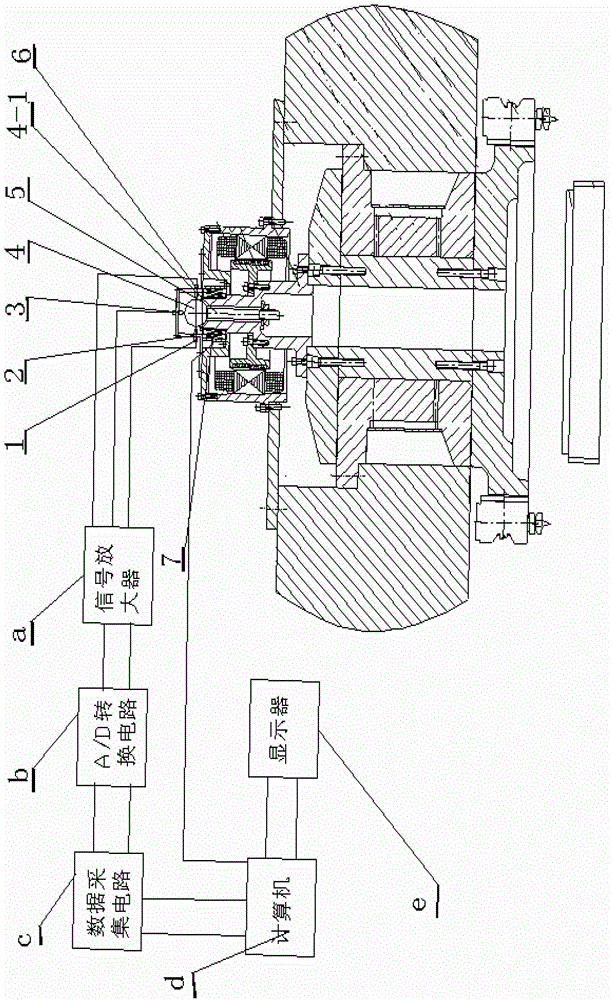

[0018] Specific implementation mode one: combine figure 1 Describe this embodiment. The device for online measurement of the dynamic performance of an ultra-precision static pressure spindle described in this embodiment includes a signal acquisition unit and a data processing unit. The signal acquisition unit includes a No. 1 high-precision displacement sensor 1 and a sensor bracket 2 , No. 2 high-precision displacement sensor 3, standard ball 4, detection rod 4-1, No. 3 high-precision displacement sensor 6 and rotary encoder 7; the rear end surface of the rotor in the ultra-precision static pressure spindle is processed into a tapered shape as a measurement reference face 5;

[0019] One end of the detection rod 4-1 is fixedly connected with the standard ball 4, and the other end of the detection rod 4-1 is threaded, and is connected to the internal step of the hollow main shaft through the thread, and the standard ball 4 is closely attached to the tapered measurement reference

specific Embodiment approach 2

[0024]Specific Embodiment 2. This embodiment is a further description of the device for online measurement of the dynamic performance of an ultra-precision static pressure spindle described in Specific Embodiment 1. The material of the standard ball 4 is stainless steel, and the surface accuracy of the standard ball 4 after polishing is PV The value is less than λ / 20, where λ=0.633 μm, and the surface roughness is less than 2 nm.

specific Embodiment approach 3

[0025] Specific Embodiment 3. This embodiment is a further description of the device for online measurement of the dynamic performance of an ultra-precision static pressure spindle described in Specific Embodiment 1. No. 1 high-precision displacement sensor 1, No. 2 high-precision displacement sensor 3 and No. 3 The high-precision displacement sensors 6 all adopt capacitive sensors, and the resolution of the capacitive sensors is less than 1 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap