Rotary support structure for sensors

A rotating support and sensor technology, applied in the direction of instruments, liquid level indicators, machines/engines, etc., can solve the problems of shaft deflection deviation, inaccurate measurement accuracy, and affecting the service life of Hall sensors, etc., to achieve structural stability and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

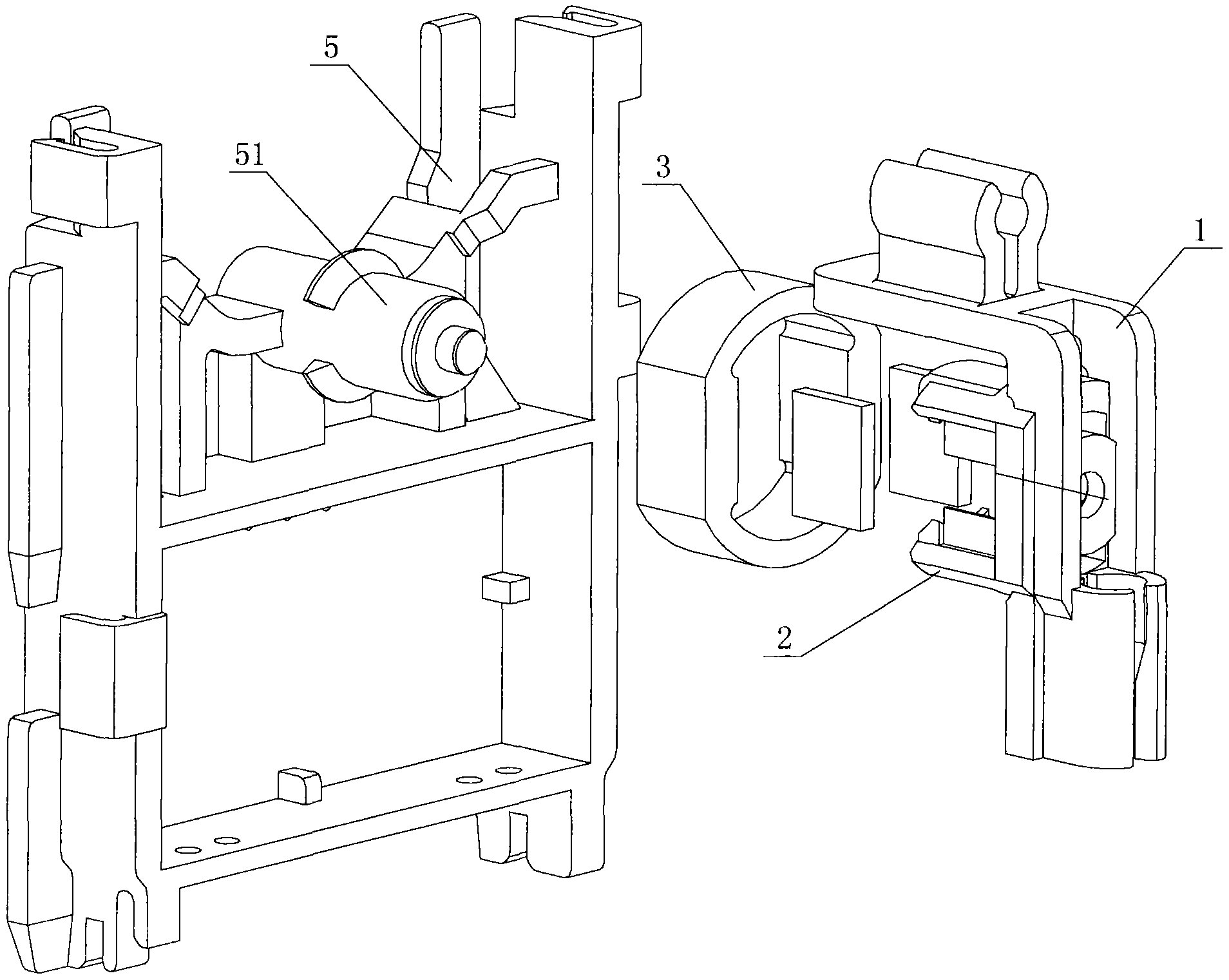

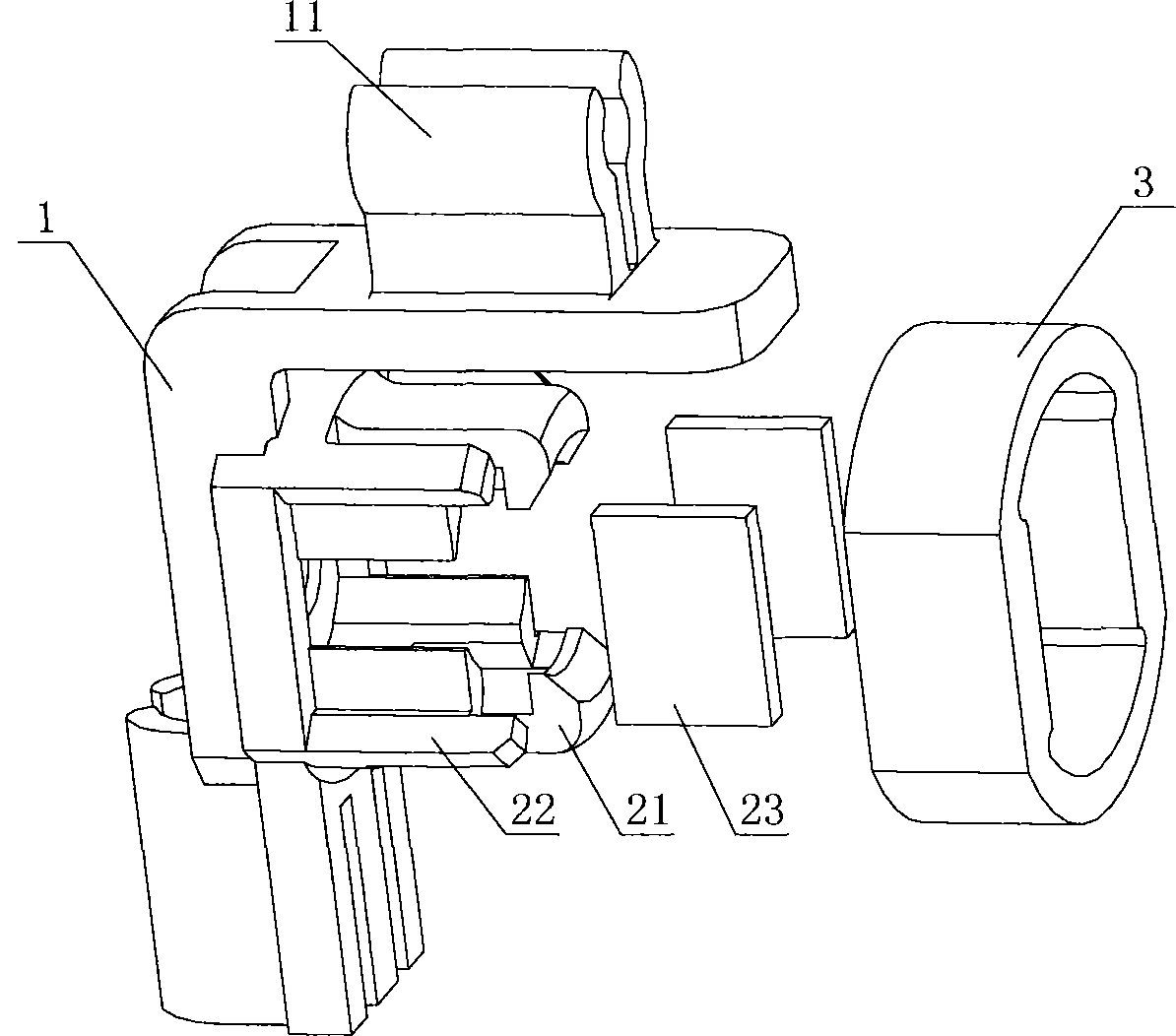

[0009] Such as Figure 1-2 As shown, the sensor rotation support structure described in the embodiment of the present invention is installed on the rotating shaft 51 of the Hall sensor 5, including the floating rod connecting part 1 connected with the floating rod, the rotating shaft connecting part 2 connected and positioned with the rotating shaft 51, A fixed sleeve 3 for positioning the auxiliary shaft connector 2, the floating rod connector 1 is connected to the rotating shaft connector 2, preferably, the floating rod connector 1 and the rotating shaft connector 2 are integrally formed; the floating rod connector 1 is L-shaped, and a floating rod connecting groove 11 is respectively provided on the top surface and the outer surface of the floating rod connecting part 1. The floating rod connecting groove 11 is an open structure, and the inner wall of the floating rod connecting groove 11 is cylindrical; The rotating shaft connector 2 is located on the inner surface of the flo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap