Five-toe shoe and making method thereof

A production method and technology for five-toed shoes, which are applied to shoe lasts, footwear, clothing, etc., can solve the problems of blisters, blood blisters or dry calluses and discomfort caused by grinding toes, and achieve the effect of increasing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

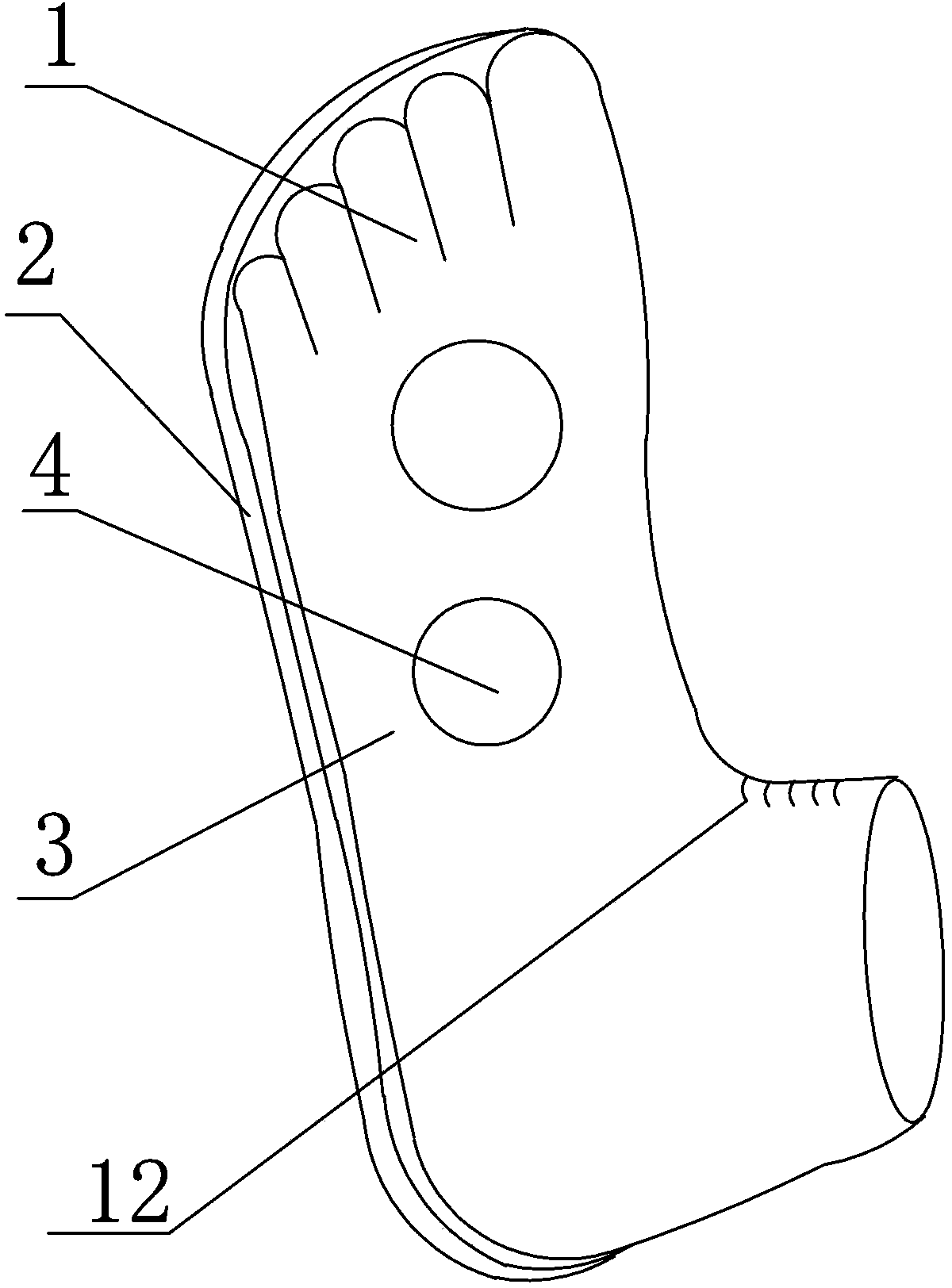

[0023] The five-toed shoes of the present invention include sole 2, vamp 3, five toes 1, shoelaces 12, the five toes 1 and vamp 3 are integrally formed, there is no seam on the five toes 1, and the front end of the five toes 1 Made of two pieces stacked together. The upper 3 has a printed or knitted pattern 4 thereon.

[0024] A method for making the above-mentioned five-toed shoes, comprising the steps of:

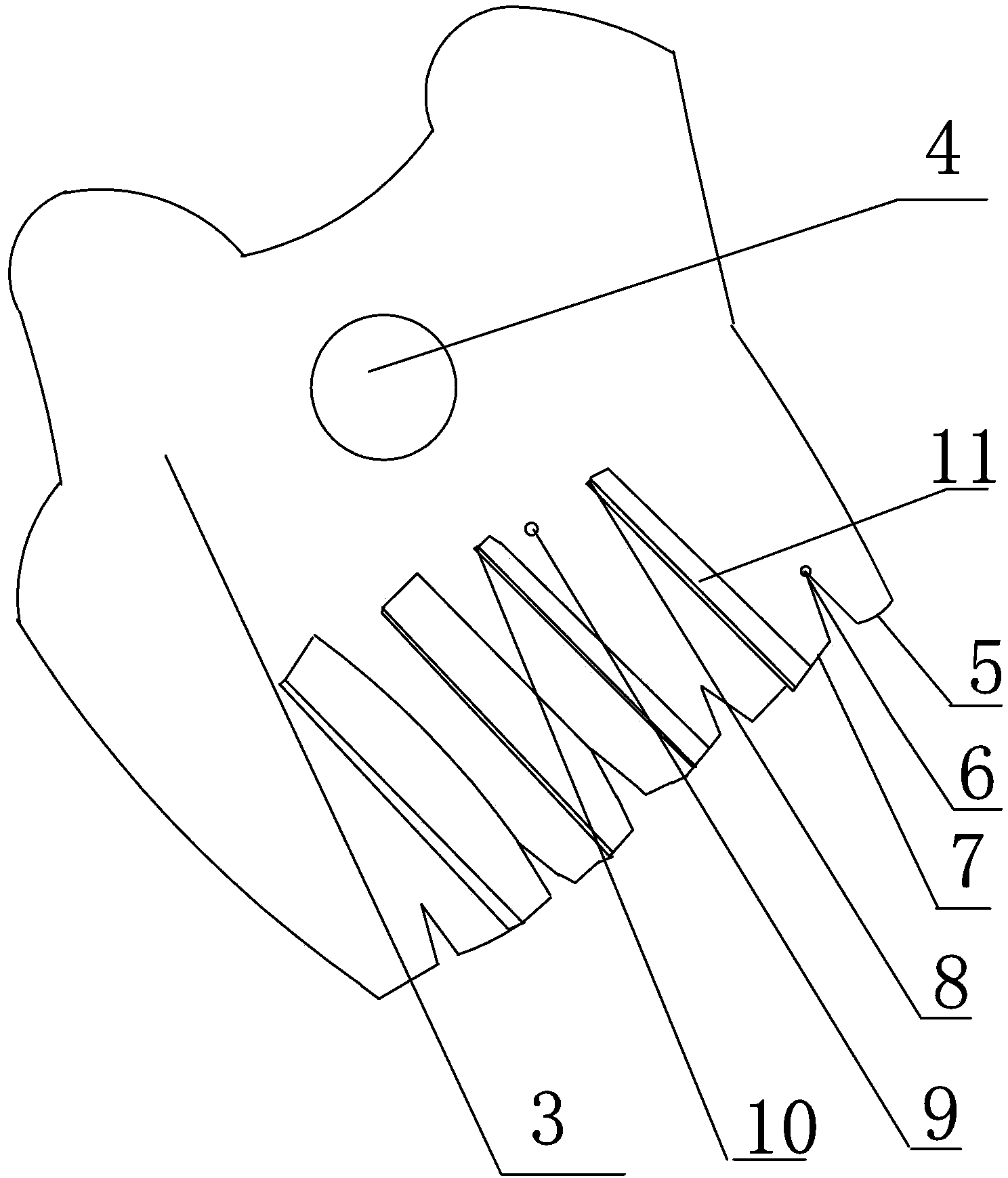

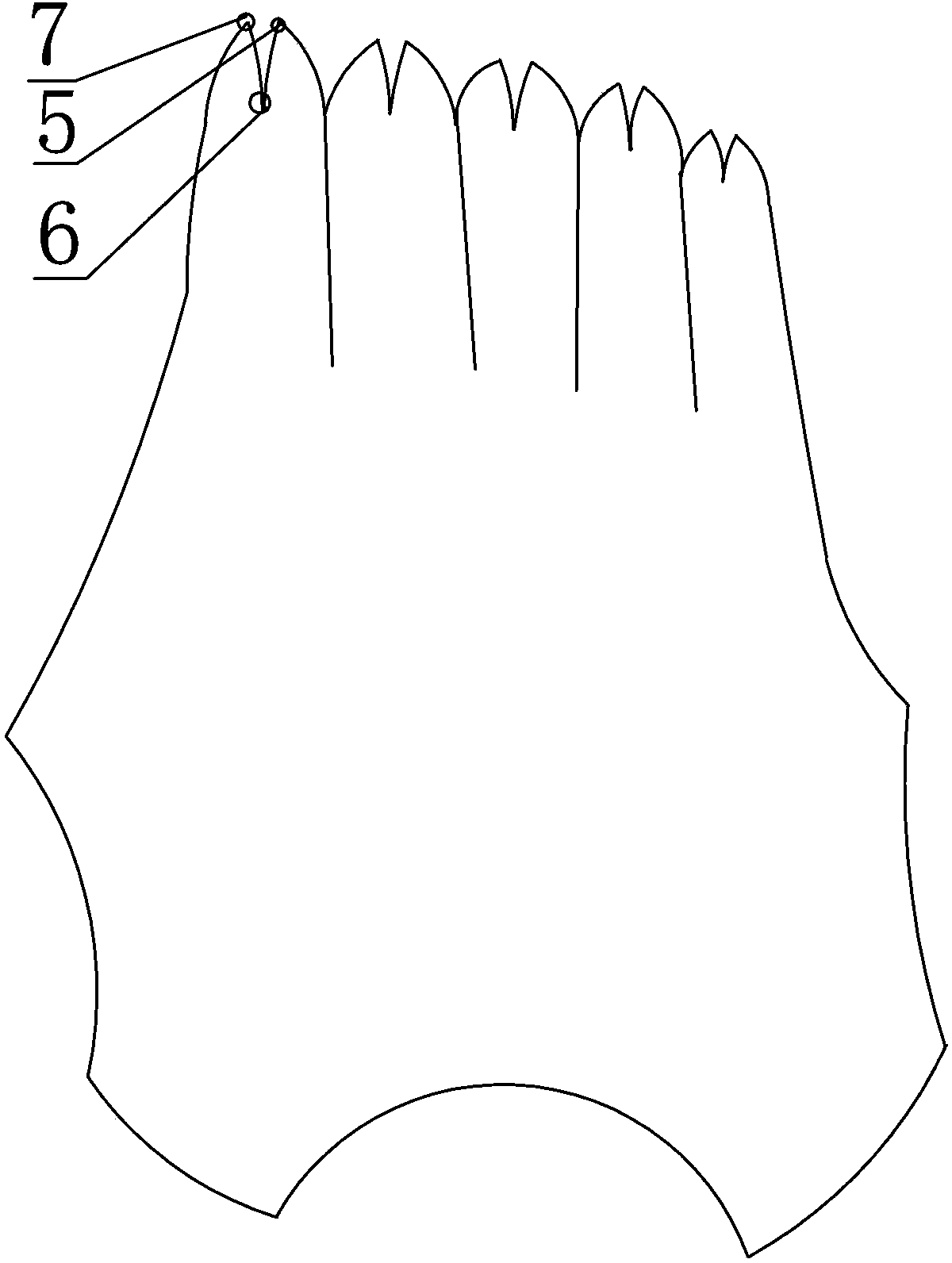

[0025] 1. Take the elastic textile material, divide the front end of each toe into two pieces, start weaving from one piece (5) of the front end of the first toe, and return to the other piece (7) when weaving to the intersection (6) ) and start weaving at the intersection (6), the two pieces are combined into one piece and weaved together. When the length of the first toe is reached, that is, when the weaving reaches the junction of the first toe and the upper (8), return Follow the steps above to knit the second toe.

[0026] 2. Because the position of the heel of the s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap