Textile sizing agent recycling process

A technology for recycling and processing textile pulp, which is applied in the textile field, can solve problems such as clogging, and achieve the effects of improving mixing, improving filtering effect, and being easy to dry and handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

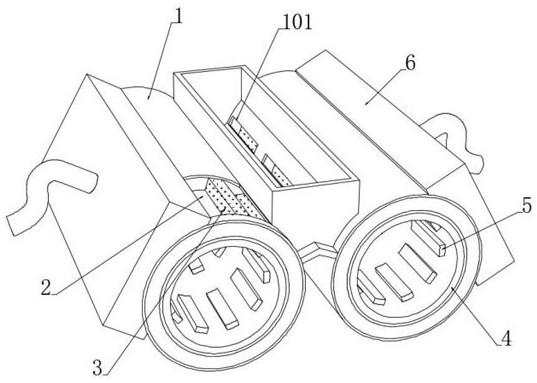

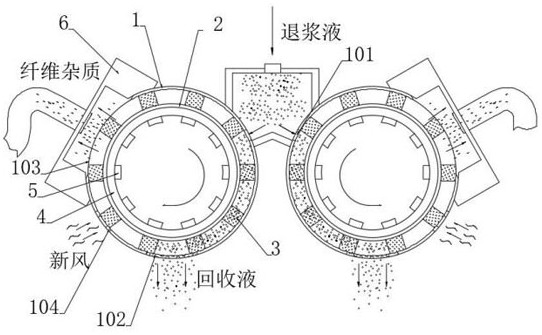

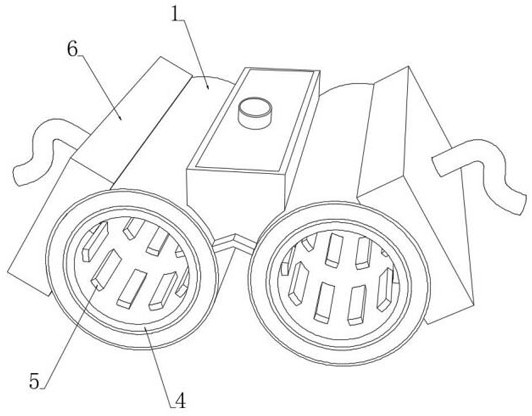

[0041] see Figure 1-4 , washing the warp yarn after desizing treatment to obtain a washing liquid, collecting the washing liquid and the solution in the desizing process to obtain a desizing liquid; introducing the desizing liquid into the outer ring through the size inlet 101 on a pair of outer ring sleeves 1 In the ring sleeve 1, use the overflow air filter layer installed in the outer ring sleeve 1 to absorb the fiber impurities in the desizing liquid, and use the impact force of the desizing liquid to drive the overflow air filter layer to rotate during the filtration process; The inner wall is heated, and the overflow air filter layer that rotates upward is dried; the recovered liquid obtained after filtration overflows through the drain hole 102 at the bottom of the outer ring sleeve 1, and then the overflow air that rotates upward and is dried is filtered layer for the removal of fiber impurities.

[0042] A heat conduction ring 4 is installed on the inner wall of the in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap