Multifunctional manipulator for plastic product molding

A technology for multifunctional manipulators and plastic products, which is applied in the field of industrial automation machinery, can solve the problems of affecting the molding efficiency of plastic products, increasing the workload of management and maintenance, and the low cost of plastic products, etc., so as to reduce the amount of equipment investment, The effect of saving manpower and equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

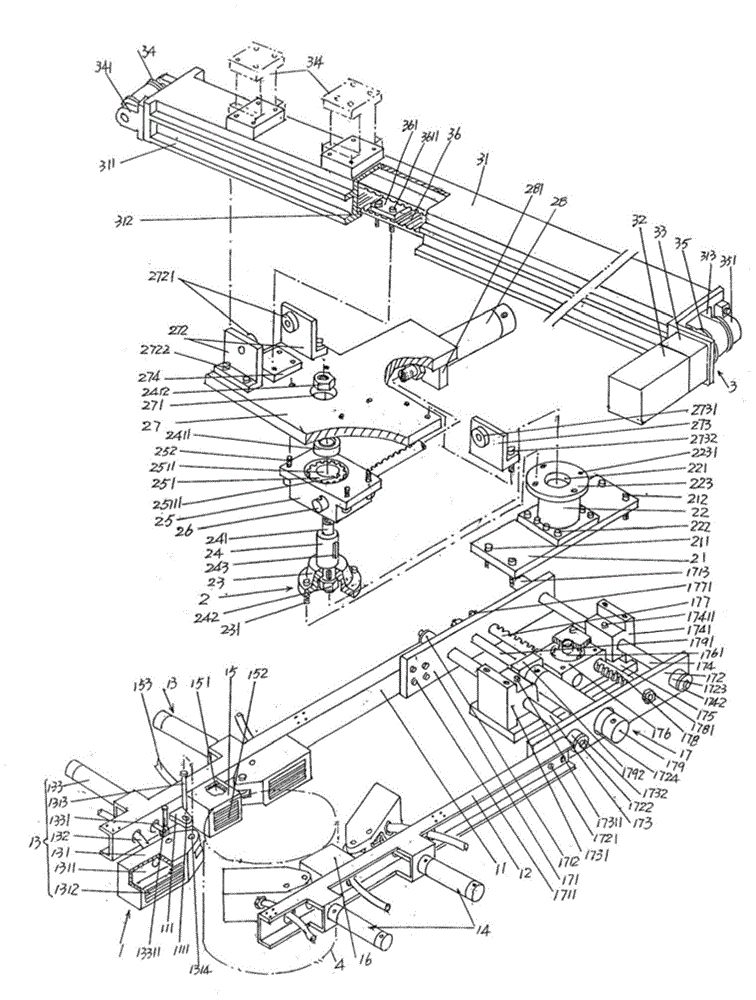

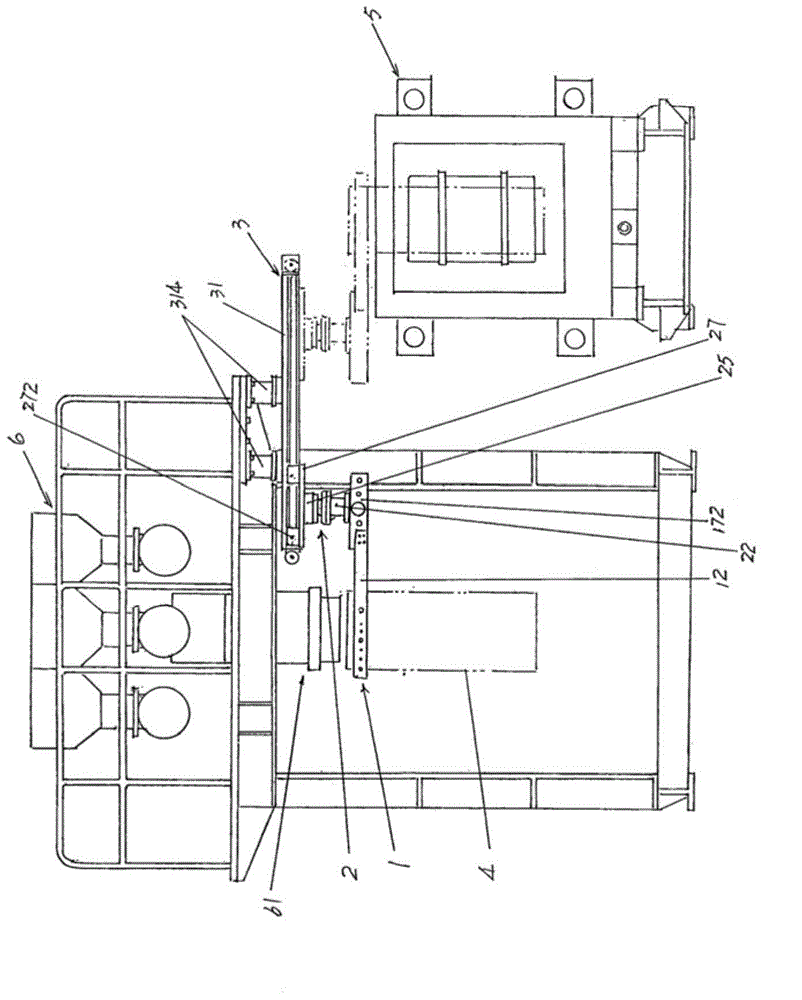

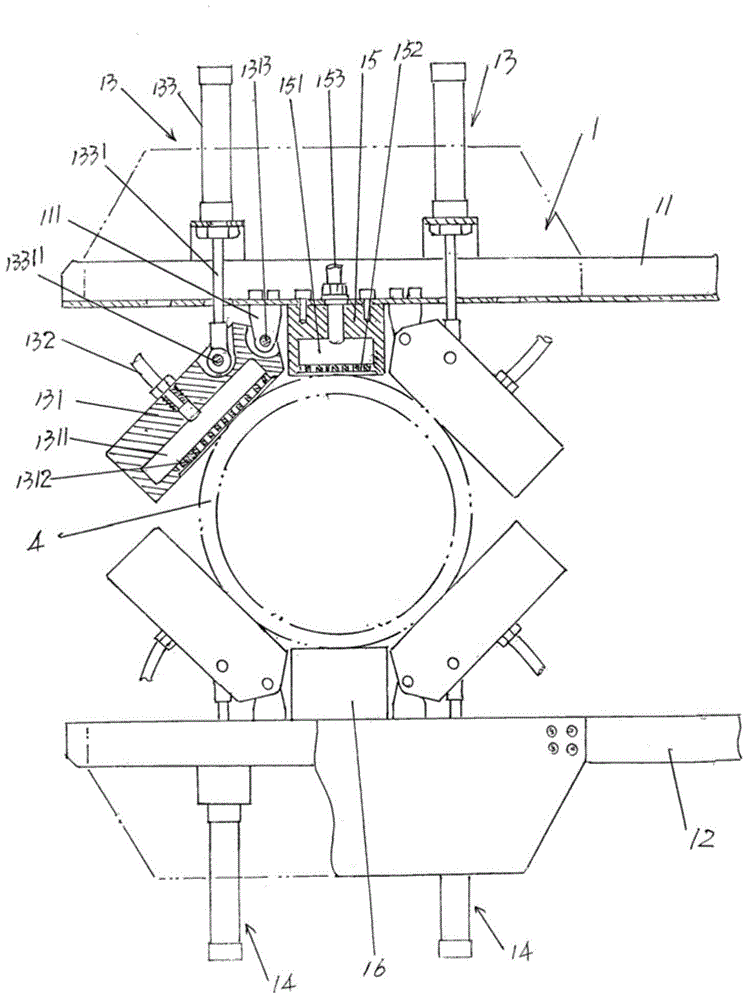

[0024] See figure 1 and figure 2 , a parison support release mechanism 1 is provided, the parison 4 shown in the figure is supported by the parison support release mechanism 1, and transferred to the opening and closing mold mechanism 5 in the support state ( image 3 shown), inflated by the inflation mechanism, the parison 4 is formed by image 3 The parison extruding mechanism 61 of the schematic hollow plastic product forming machine 6 extrudes. The mold opening and closing mechanism 5 mentioned here can also be called a plastic product molding mechanism (hereinafter the same).

[0025] The preferred structure of the above-mentioned parison support release mechanism 1 is as follows: including left and right clamping arms 11,12, a pair of left suction devices 13, a pair of right suction devices 14, left and right fixed suction blocks 15,16 and clips The arm opening and closing device 17, the left and right clamping arms 11, 12 form a parallel relationship with each other, a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap