Data collection and analysis device for cigarette packing machine

A data acquisition and analysis, packaging machine technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problem of not being able to truly reflect the actual situation of the production site, and achieve the effect of complete data and reliable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

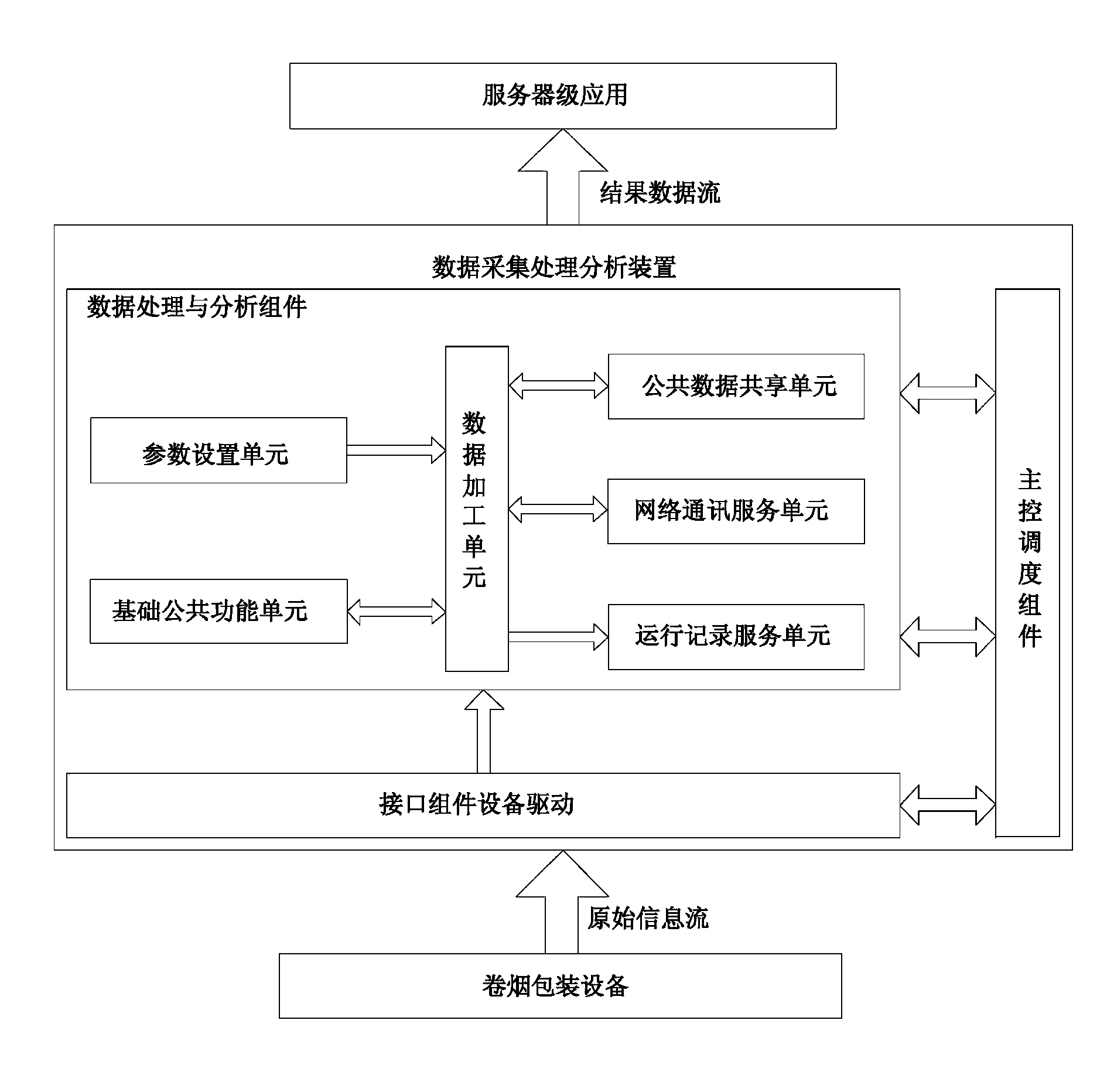

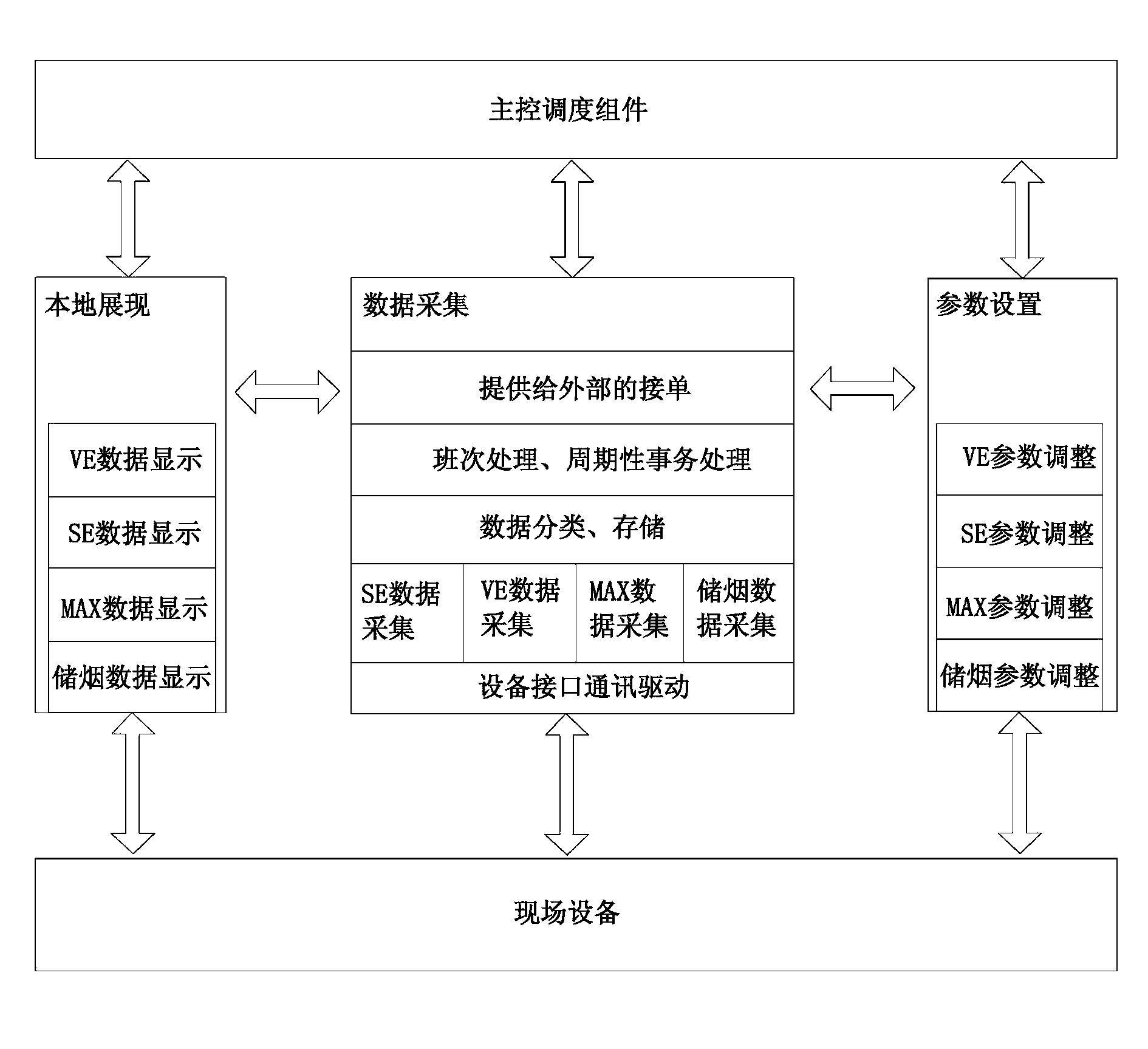

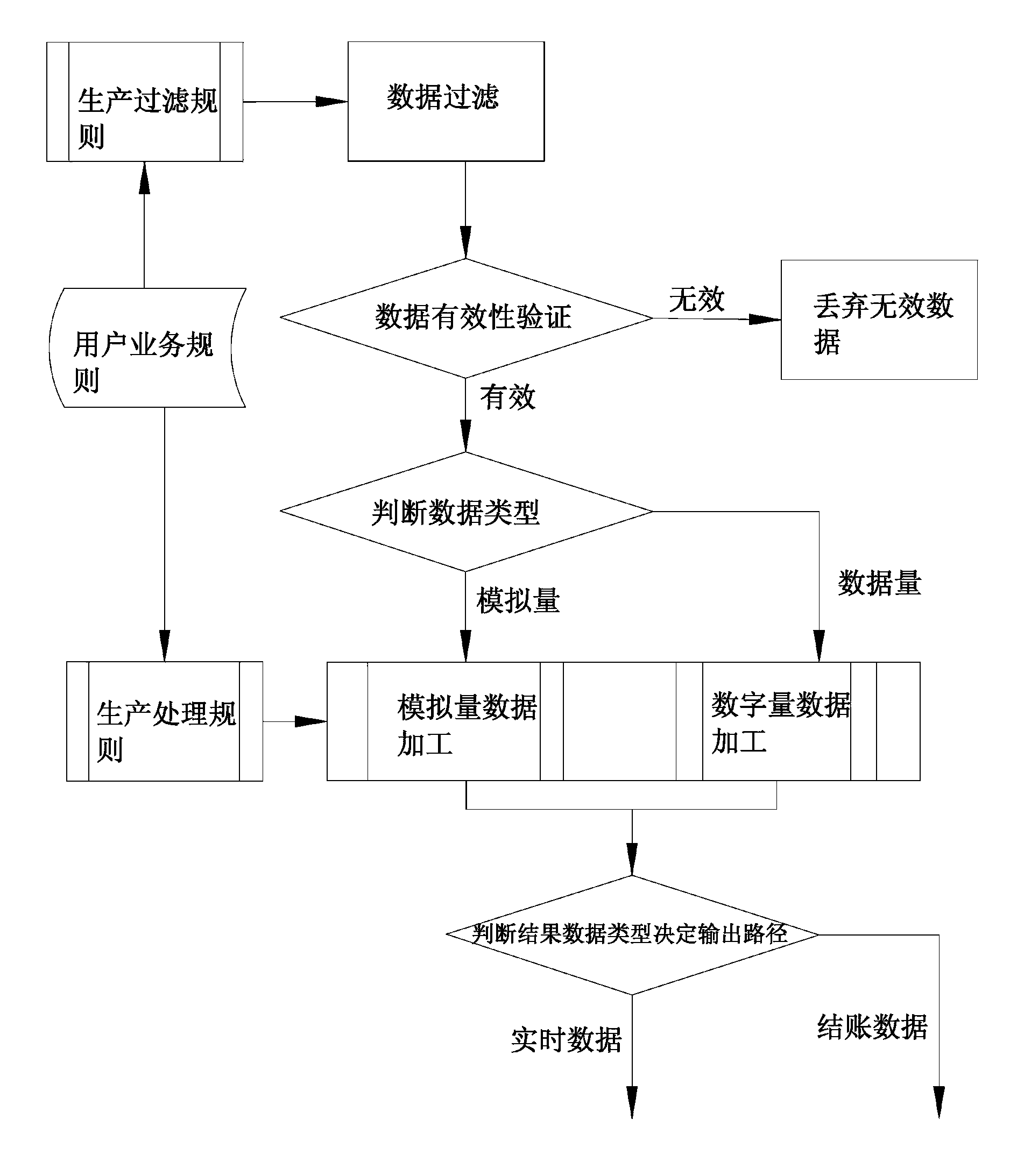

[0028] Such as figure 1 Shown is a data acquisition and analysis device for cigarette packaging machines. This data acquisition and analysis device is applied to the data acquisition of cigarette packaging equipment in tobacco industry enterprises, which meets the requirements of the management information system for real-time data acquisition. Secondly, the analysis of the device And the design process applies object-oriented thinking, which has the characteristics of componentization and easy expansion. The main function of the data acquisition and analysis device is to process and analyze the raw data of the acquisition equipment according to certain rules, and finally obtain the data information in the user's ideal format.

[0029] The data acquisition and analysis device of the present invention is mainly composed of a data processing and analysis component connected to an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap