Temperature-stabilized pyrochlore complex-phase dielectric ceramics and preparation method thereof

A temperature-stable, dielectric ceramic technology, applied in the field of temperature-stable pyrochlore composite-phase dielectric ceramics and its preparation, can solve the problems of degraded material dielectric properties, rare high-frequency dielectric material system, and small dielectric constant. , achieve the effects of curbing the deterioration of dielectric properties, excellent high-frequency dielectric properties, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

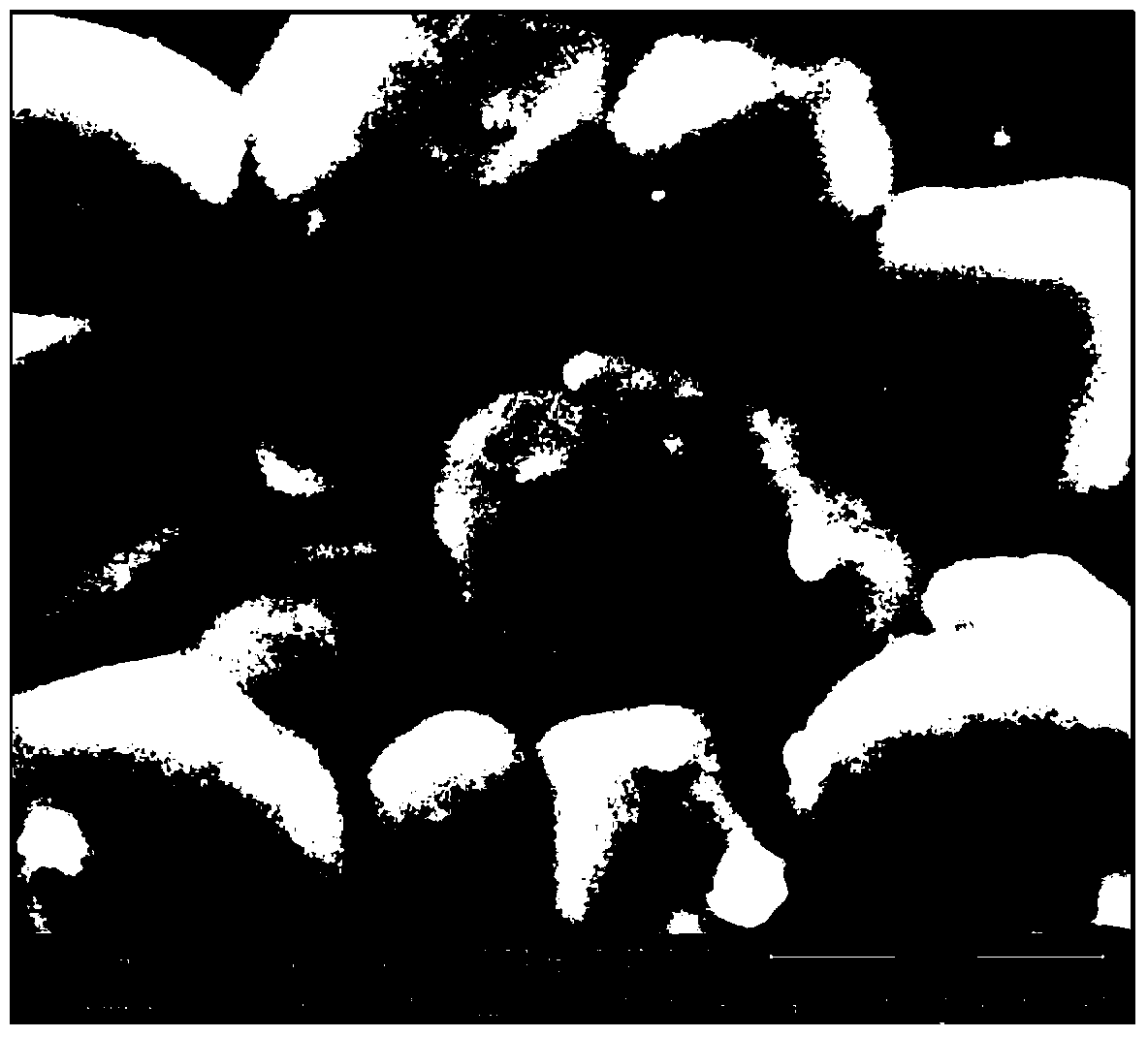

Image

Examples

Example Embodiment

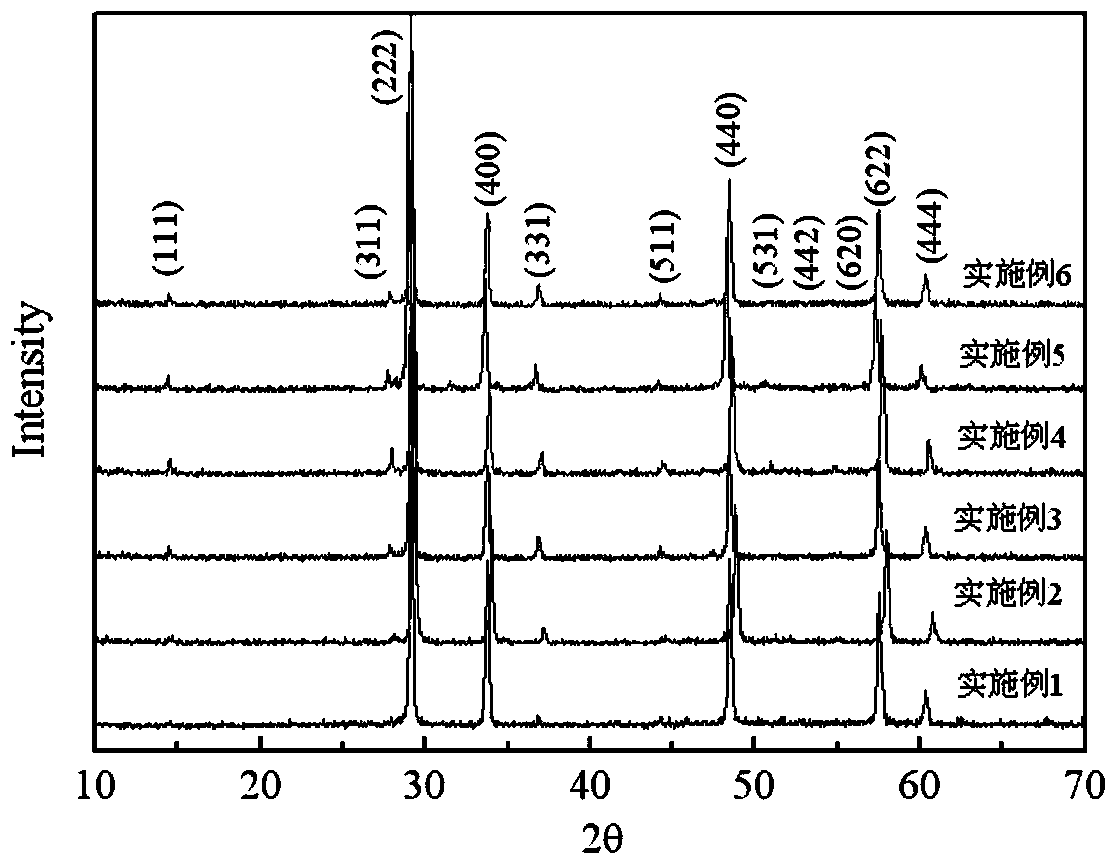

[0034] Example 1

[0035] The general formula of the stoichiometric ratio of the temperature-stabilized pyrochlore multiphase dielectric ceramic of this embodiment is: 0.8 (Bi 1.5 Zn 0.5 )(Zr 1.5 Nb 0.5 )O 7 +0.2(Bi 1.5 Zn 0.5 )(Zn 0.5 Nb 1.5 )O 7 .

[0036] The preparation method of the temperature-stabilized pyrochlore multiphase dielectric ceramic of the present embodiment is:

[0037] Step 1. Adopt Bi with a mass purity of 99% 2 O 3 Powder, ZnO powder with mass purity of 99.8%, Nb with mass purity of 99.5% 2 O 5 Powder and ZrO with a mass purity of 99% 2 Powder is the raw material, according to the chemical formula (Bi 1.5 Zn 0.5 )(Zr 1.5 Nb 0.5 )O 7 and (Bi 1.5 Zn 0.5 )(Zn 0.5 Nb 1.5 )O 7 ingredients separately;

[0038] Step 2, mix the raw materials after batching in step 1 and place them in a planetary ball mill for ball milling for 5h to obtain slurry;

[0039] Step 3. After drying the slurry described in step 2, heat it to 820 ° C for pre-synthe

Example Embodiment

[0045] Example 2

[0046] The general formula of the stoichiometric ratio of the temperature-stabilized pyrochlore multiphase dielectric ceramic of this embodiment is: 0.7 (Bi 1.5 Zn 0.5 )(Zr 1.5 Nb 0.5 )O 7 +0.3(Bi 1.5 Zn 0.5 )(Zn 0.5 Nb 1.5 )O 7 .

[0047] The preparation method of the temperature-stabilized pyrochlore multiphase dielectric ceramic of the present embodiment is:

[0048] Step 1. Adopt Bi with a mass purity of 99% 2 O 3 Powder, ZnO powder with mass purity of 99.8%, Nb with mass purity of 99.5% 2 O 5 Powder and ZrO with a mass purity of 99% 2 Powder is the raw material, according to the chemical formula (Bi 1.5 Zn 0.5 )(Zr 1.5 Nb 0.5 )O 7 and (Bi 1.5 Zn 0.5 )(Zn 0.5 Nb 1.5 )O 7 ingredients separately;

[0049] Step 2, mixing the raw materials batched in step 1 and then placing them in a planetary ball mill for ball milling for 4 hours to obtain slurry;

[0050] Step 3, drying the slurry described in step 2 and heating to 810 ° C for pre-s

Example Embodiment

[0056] Example 3

[0057] The general formula of the stoichiometric ratio of the temperature-stabilized pyrochlore multiphase dielectric ceramic of this embodiment is: 0.65 (Bi 1.5 Zn 0.5 )(Zr 1.5 Nb 0.5 )O 7 +0.35(Bi 1.5 Zn 0.5 )(Zn 0.5 Nb 1.5 )O 7 .

[0058] The preparation method of the temperature-stabilized pyrochlore multiphase dielectric ceramic of the present embodiment is:

[0059] Step 1. Adopt Bi with a mass purity of 99% 2 O 3 Powder, ZnO powder with mass purity of 99.8%, Nb with mass purity of 99.5% 2 O 5 Powder and ZrO with a mass purity of 99% 2 Powder is the raw material, according to the chemical formula (Bi 1.5 Zn 0.5 )(Zr 1.5 Nb 0.5 )O 7 and (Bi 1.5 Zn 0.5 )(Zn 0.5 Nb 1.5 )O 7 ingredients separately;

[0060] Step 2, mix the raw materials after batching in step 1 and place them in a planetary ball mill for ball milling for 6h to obtain slurry;

[0061] Step 3, drying the slurry described in step 2 and heating it to 800 ° C for pre-synt

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature coefficient of dielectric constant | aaaaa | aaaaa |

| Temperature coefficient of dielectric constant | aaaaa | aaaaa |

| Temperature coefficient of dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap