2,4-D dimethylamine salt soluble granule and preparation method for soluble granule

A technology of dimethylamine salt and soluble granules, applied in 2 fields, to achieve the effects of excellent dissolving and dispersing performance, high particle strength, convenient use and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] Example 1:

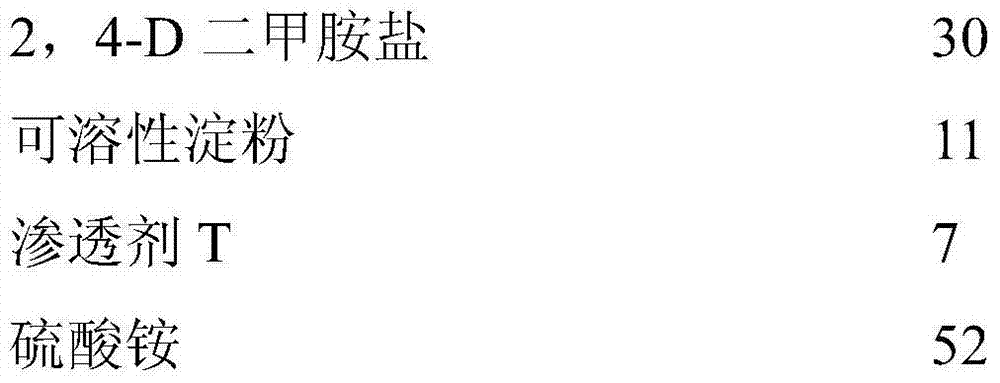

[0014] Its components and their weight percentages are as follows:

[0015]

[0016] Adopt turntable granulation method. Mix 2,4-D dimethylamine salt, penetrant T, and ammonium sulfate thoroughly to prepare 2,4-D dimethylamine salt soluble powder, and then add 2,4-D dimethylamine to the inclined rotating disk. The amine salt soluble powder is sprayed into the soluble starch aqueous solution for granulation, and the obtained granules are dried to obtain 2,4-D dimethylamine salt soluble granules.

Example Embodiment

[0017] Example 2:

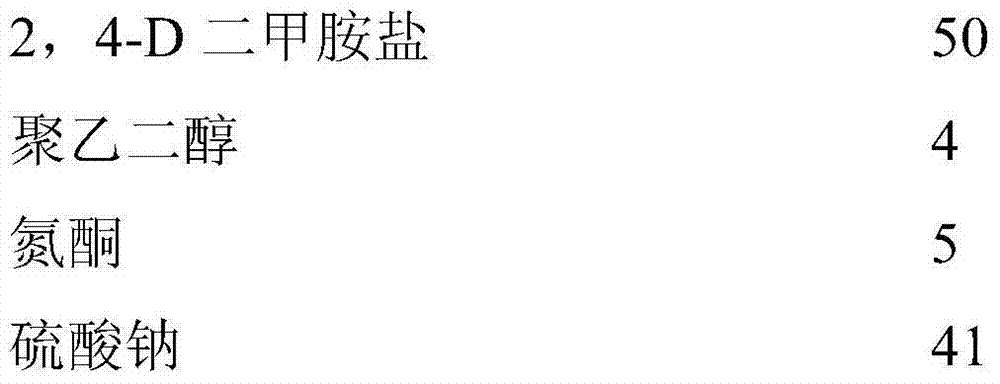

[0018] Its components and their weight percentages are as follows:

[0019]

[0020] Using screw extrusion granulation method. The 2,4-D dimethylamine salt, sodium sulfate, and azone are thoroughly mixed, transferred to a mixer, sprayed into an aqueous solution of polyethylene glycol, and mixed thoroughly. The obtained material is granulated and dried to obtain 2,4-D dimethylamine salt soluble granules.

Example Embodiment

[0021] Example 3:

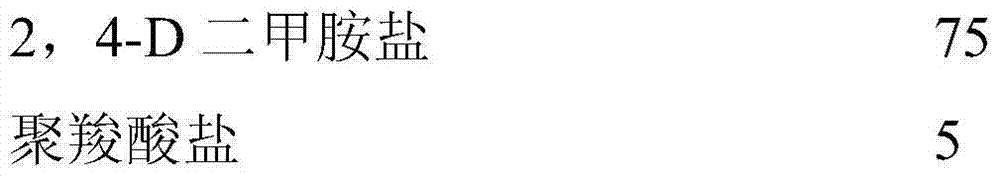

[0022] Its components and their weight percentages are as follows:

[0023]

[0024]

[0025] Using screw extrusion granulation method. All the above components are fully mixed and transferred to a screw extrusion granulator for granulation, which is 2,4-D dimethylamine salt soluble granules.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap