Rice noodles and preparation method thereof

A technology of rice flour and corn starch, applied in the field of food processing, can solve the problems of affecting the taste and quality of rice flour, affecting people's health, and having a single taste, and achieve the effects of increasing smooth taste, improving toughness, and increasing water retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation of embodiment 1 tartary buckwheat rice flour

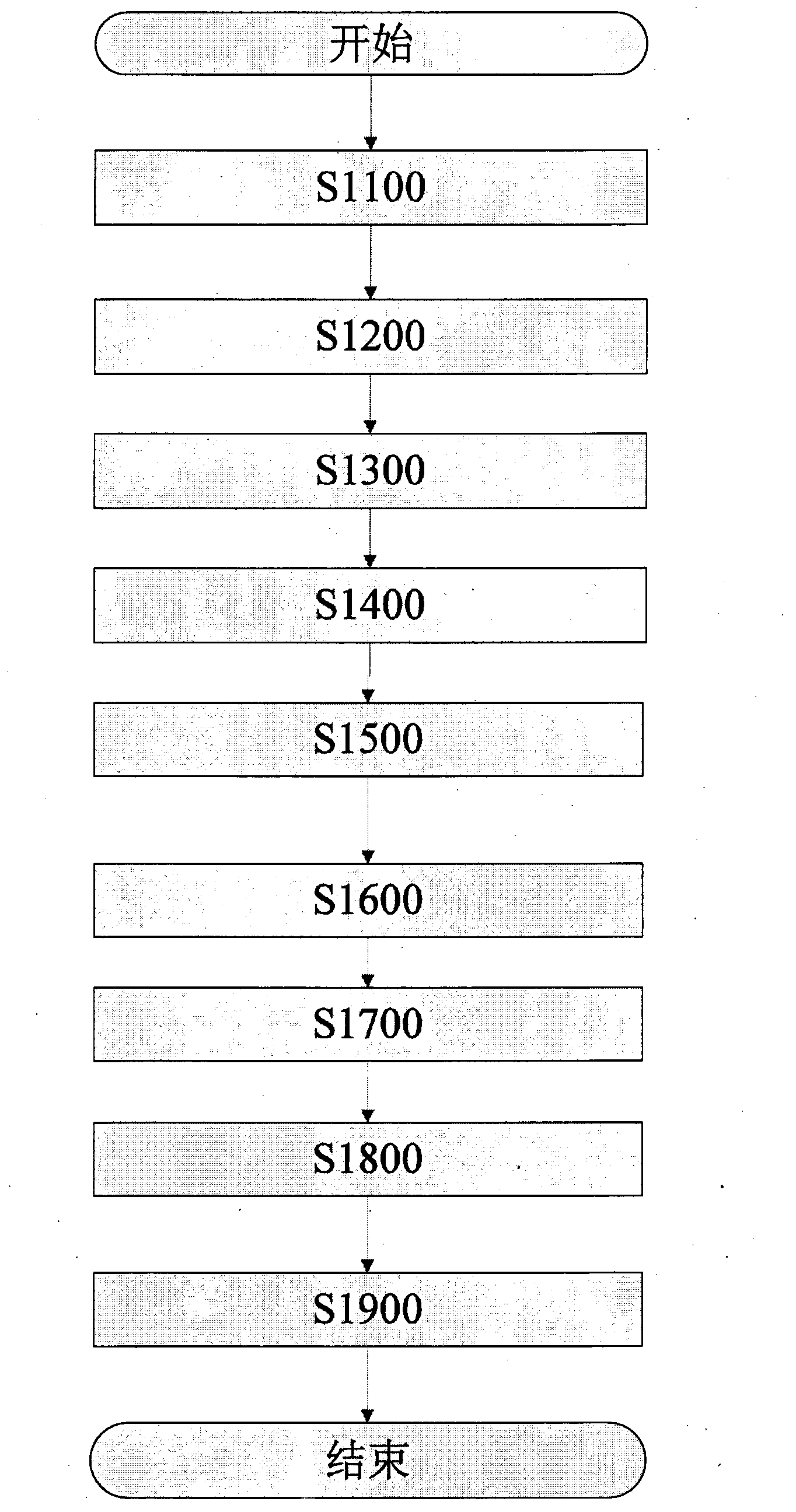

[0020] according to figure 1 The preparation method of the shown rice flour firstly selects the raw materials in step S1100, selects medium indica rice, konjac flour, cornstarch, hybrid rice flour and tartary buckwheat flour as raw materials; Perform the cleaning operation of step S1200 in the jet rice washing machine; then perform the soaking operation of step S1300 on the cleaned medium indica rice; then perform the water filtration operation of step S1400 on the soaked medium indica rice; The rice is subjected to the pulverization operation of step S1500 in the pulverizer; then the rice milk obtained by pulverization to obtain medium indica rice is subjected to the adjustment of the most critical step S1600 of the present invention moisture Operation, in this step, add 5-40 parts of cornstarch, 0.05-5 parts of konjac flour and 1-3 parts of tartary buckwheat flour to the slurry obtained by crushing 100 par

Embodiment 2

[0021] The preparation of embodiment 2 walnut rice flour

[0022] according to figure 1 The preparation method of the rice flour shown, first carried out the selection of raw materials in step S1100, selected medium indica rice, konjac flour, cornstarch, hybrid rice flour and walnut powder as raw materials; 100 parts of selected medium indica rice were washed in the jet stream Carry out the cleaning operation of step S1200 in the machine; then perform the soaking operation of step S1300 on the cleaned medium indica rice; then perform the water filtration operation of step S1400 on the soaked medium indica rice; then put the filtered medium indica rice in Carry out the pulverizing operation of step S1500 in the pulverizer; then, the slurry obtained by pulverizing medium indica rice is carried out to adjust the most critical step S1600 of the present invention moisture In this step, add 5-40 parts of cornstarch, 0.05-5 parts of konjac powder and 1-3 parts of walnut powder to the

Embodiment 3

[0023] The preparation of embodiment 3 vegetable juice rice noodles

[0024] according to figure 1 The preparation method of the shown rice flour firstly selects the raw materials in step S1100, selects medium indica rice, konjac flour, cornstarch, hybrid rice flour and vegetable juice as raw materials; washes 100 parts of medium indica rice in the jet stream Carry out the cleaning operation of step S1200 in the machine; then perform the soaking operation of step S1300 on the cleaned medium indica rice; then perform the water filtration operation of step S1400 on the soaked medium indica rice; then put the filtered medium indica rice in Carry out the pulverization operation of step S1500 in the pulverizer; then carry out the most critical step S1600 adjustment of the present invention by pulverizing to obtain the slurry of medium indica rice moisture In this step, add 5-40 parts of cornstarch, 0.05-5 parts of konjac powder and 1-3 parts of walnut powder to the slurry obtained

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap