Preparation method for producing germinated glutinous brown rice flour with low glycemic index by microwave combined heat-moisture treatment

A technology of low glycemic index and germinated glutinous brown rice, which is applied in the field of food processing, can solve problems such as limiting the application range of glutinous rice flour, and achieve the effects of increasing the content of digestible starch, reducing production costs, and increasing the content of digestible starch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

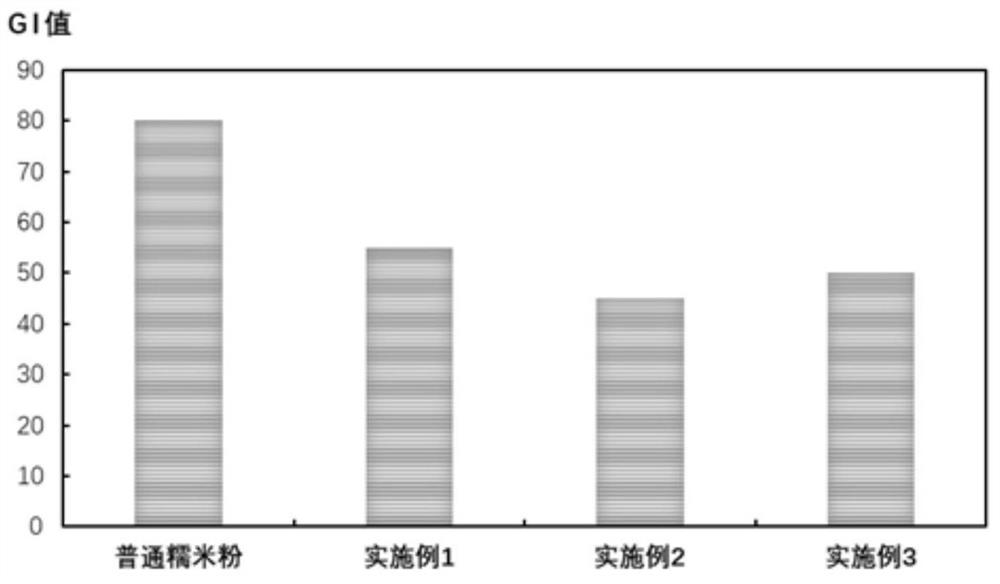

Embodiment 1

[0025] Example 1: A preparation method for producing germinated glutinous brown rice flour with low glycemic index by microwave combined with heat and humidity treatment

[0026] Wash the glutinous brown rice and germinate it in an automatic hypoxic stress germination machine for 16 hours. The temperature is controlled at 35°C and the dissolved oxygen concentration is maintained at 3 mg / L. After the germinated glutinous brown rice is simply washed, the amount of water added is controlled between 1:1, and then it is crushed by wet method. The pulverized germinated glutinous brown rice slurry was treated at 55°C for 60 seconds under the condition of microwave power 200W, thereby increasing the activity of endogenous proteases, followed by incubation for 80 minutes, and the stirring speed of the enzymatic conditioning reaction was 20rpm; the processed rice slurry The plate and frame filter press is used to squeeze the water, and the moisture content is controlled to 25% after hot

Embodiment 2

[0027] Example 2: A preparation method for producing germinated glutinous brown rice flour with low glycemic index by microwave combined with heat and humidity treatment

[0028] Wash the glutinous brown rice and germinate it in an automatic hypoxic stress germination machine for 20 hours. The temperature is controlled at 40°C and the dissolved oxygen concentration is maintained at 5 mg / L. After the germinated glutinous brown rice is simply cleaned, the amount of water added is controlled between 1:1.5, and then it is crushed by wet method. The pulverized germinated glutinous brown rice slurry was treated at 50°C and microwave power 400W for 40 seconds to increase the activity of endogenous proteases, and then incubated for 60 minutes. The stirring speed of the enzymatic conditioning reaction was 80rpm; the processed rice slurry The plate and frame filter press is used to squeeze the water, and the moisture content is controlled to 20% after hot air drying, and then the wet hea

Embodiment 3

[0029] Example 3: A preparation method for producing germinated glutinous brown rice flour with low glycemic index by microwave combined with heat and humidity treatment

[0030] Wash the glutinous brown rice and germinate it in an automatic hypoxic stress germination machine for 18 hours. The temperature is controlled at 38°C and the dissolved oxygen concentration is maintained at 6 mg / L. After the germinated glutinous brown rice is simply cleaned, the amount of water added is controlled between 1:2, and then it is crushed by wet method. The pulverized germinated glutinous brown rice slurry was treated at 40°C for 20 seconds under the condition of microwave power 600W to increase the activity of endogenous proteases, followed by incubation for 40 minutes, and the stirring speed of the enzymatic conditioning reaction was 60rpm; Use a plate-and-frame filter press to squeeze water, and after drying with hot air, control the moisture content to 15%. Then, the temperature of the we

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap