Multistage centrifugal compressor and cold water type air conditioning unit provided with same

A centrifugal compressor and inner cavity technology, which is applied in the direction of machines/engines, mechanical equipment, non-variable pumps, etc., can solve the problems of low efficiency of compressors, and achieve improved efficiency, uniform gas flow, and volume expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

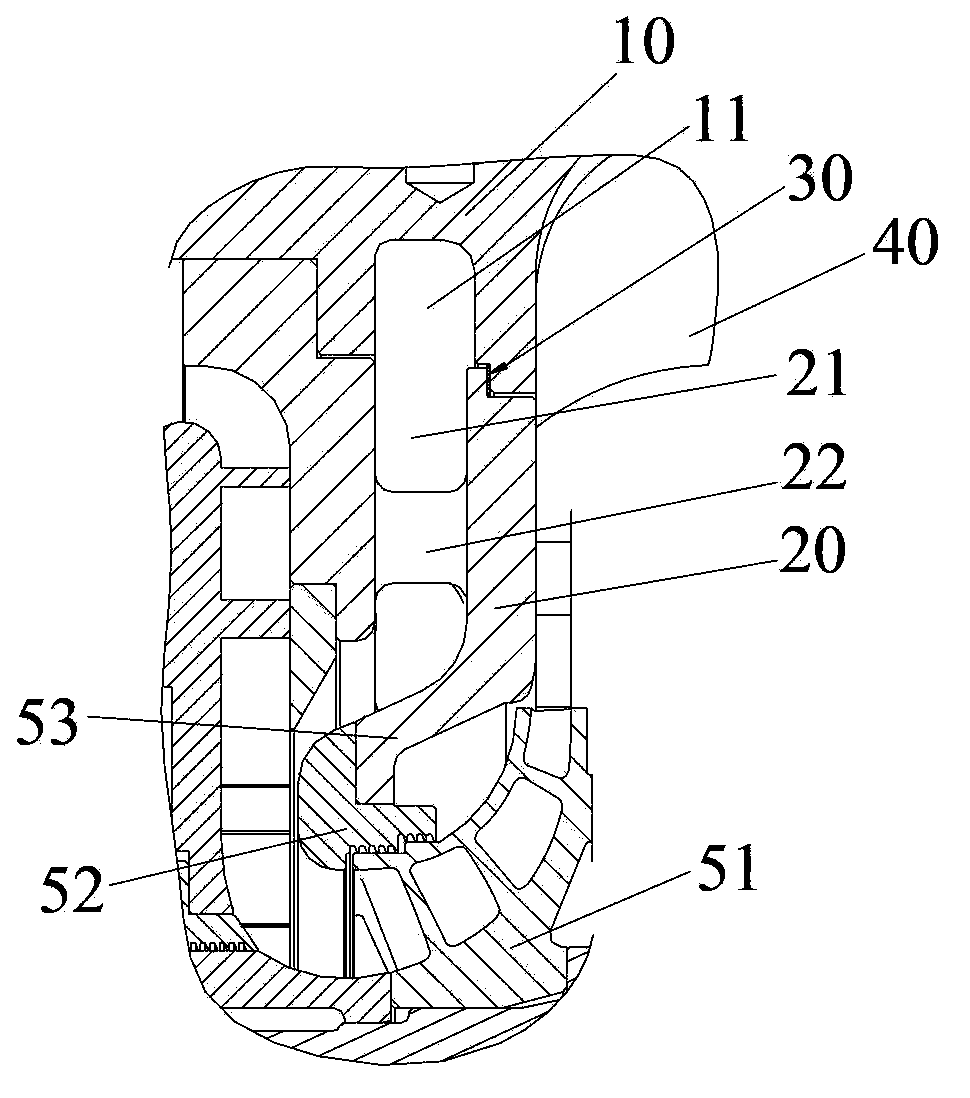

[0016] Such as figure 2 As shown, the multi-stage centrifugal compressor of this embodiment includes a casing 10 and a reflux device 20 disposed inside the casing 10. The inner wall of the casing 10 is formed with a first inner cavity 11, and the reflux device 20 is provided with a The inner cavity 11 is matched with the second inner cavity 21 , the first inner cavity 11 communicates with the second inner cavity 21 , and the first inner cavity 11 and the second inner cavity 21 form an air supply cavity of a multi-stage centrifugal compressor.

[0017] Without changing the volume of the reflux device itself, the original air supply cavity of the reflux device is transformed into an open second in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap