Permanent magnet synchronous motor device directly driving drill bit

A permanent magnet synchronous motor, a direct technology, applied in the direction of synchronous machine parts, etc., can solve the problems of large starting torque, power loss, drill string breakage, etc., to improve work efficiency, reduce energy loss, and avoid drill string breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

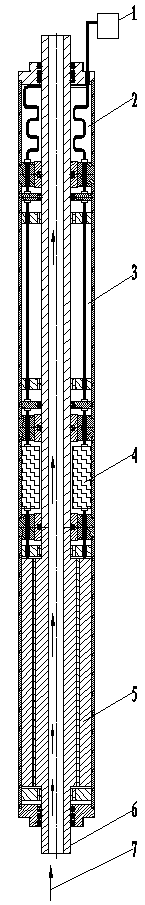

[0013] The present invention will be further described in detail in conjunction with the accompanying drawings. As shown in the figure, the rotating shaft of the permanent magnet synchronous motor 5 of the present invention is a hollow shaft 6, and the shell of the permanent magnet synchronous motor 5 and the hollow shaft 6 extend upwards. Between the shell and the hollow shaft 6 From bottom to top, there are permanent magnet synchronous motor 5, downhole controller 4, and protector 3; ground control cabinet 1 transmits power and control signals to permanent magnet synchronous motor 5 through downhole controller 4 through the electronic screen, and controls permanent magnet synchronous The motor 5 works; the upper and lower ends of the hollow shaft 6 are sealed and rotated with the casing. The cable barrel 2 arranged between the shell of the permanent magnet synchronous motor 5 and the hollow shaft 6 is located above the protector 3 . Bearings are installed between the permanent

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap