Pressure plate and side plate respectively loaded to two high-pressure areas of double-acting vane pump

A pressure plate and vane pump technology, applied in the field of hydraulic components, can solve the problems of waste, loading, and the inability to separate the pressure plate and the side plate, and achieve the effects of reducing energy loss, saving installation space, and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

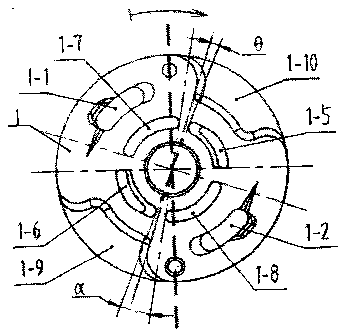

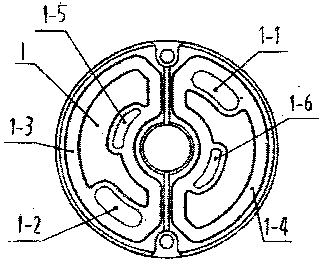

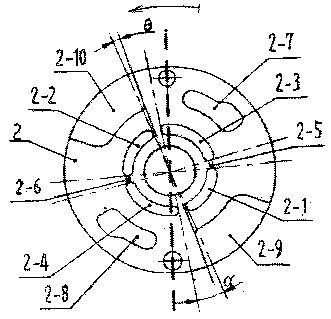

[0012] Examples, see attached Figure 1-3 The pressure plate and the side plate respectively loaded on the two high-pressure areas of the double-acting vane pump are symmetrically arranged at 180 degrees on the upper outer edge of the front of the pressure plate 1, and the oil outlet of the pressure plate 1-1 and the oil outlet of the pressure plate are provided. Two 1-2. The edge of pressure plate 1 between the head and tail of pressure plate oil outlet 1-1 and pressure plate oil outlet 2 1-2 is symmetrically provided with fan-shaped pressure plate oil suction window 1-9 and pressure plate oil suction window 2 1- 10. Out of the center hole of the pressure plate 1, there are circular pressure plate oil passage grooves 1-5, pressure plate oil passage grooves 2 1-8, pressure plate oil passage grooves 3 1-6 and pressure plate oil passage grooves 4 arranged symmetrically at 90 degrees outside the central hole of the pressure plate 1. 1-7. Pressure plate oil passage groove one 1-5

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap