Special water-cooling reflecting cover for laser processing

A technology of laser processing and reflectors, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of loss of safety protection, shielding of reflected light, and damage of reflectors, so as to ensure the safety of surrounding personnel and equipment and improve The effect of the factor of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

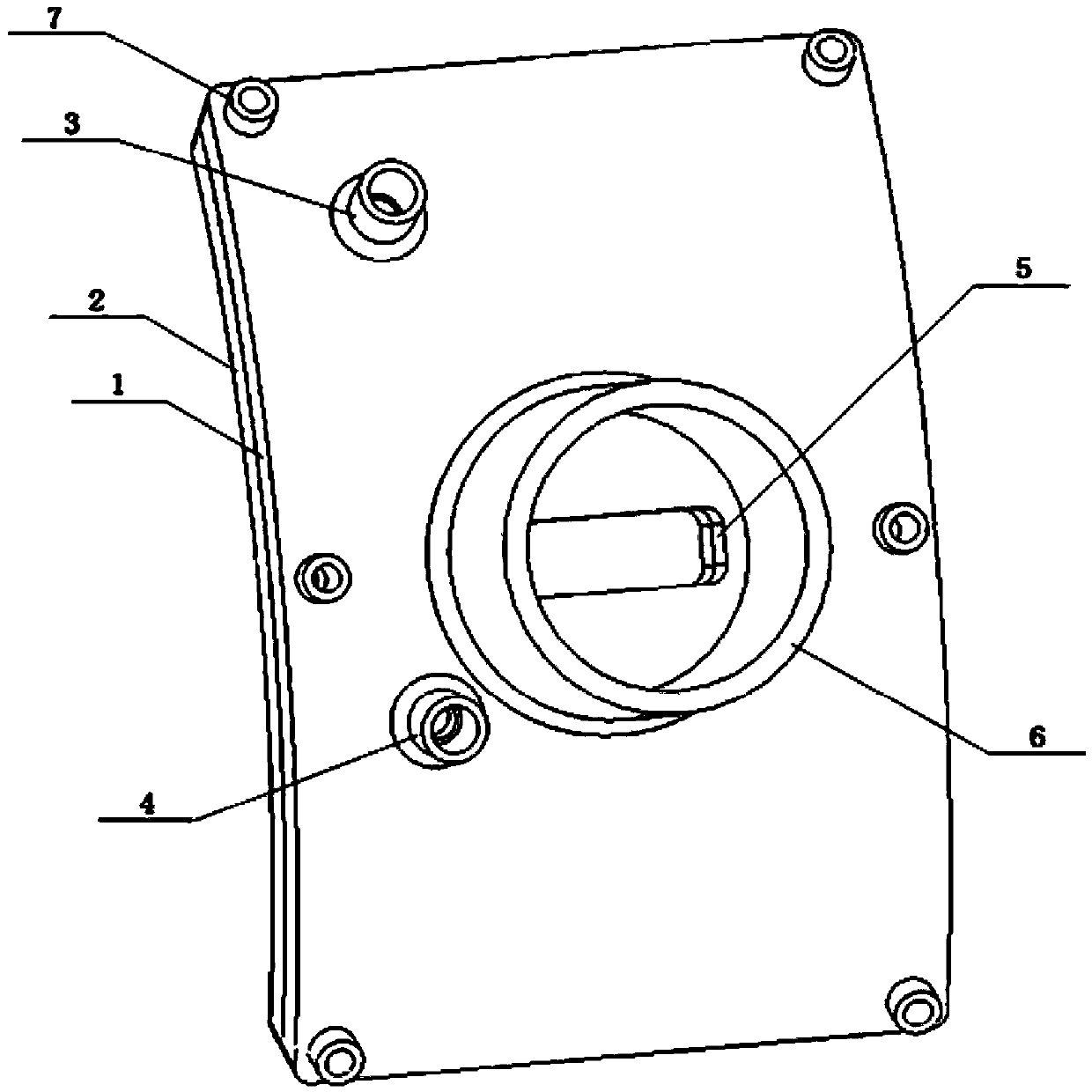

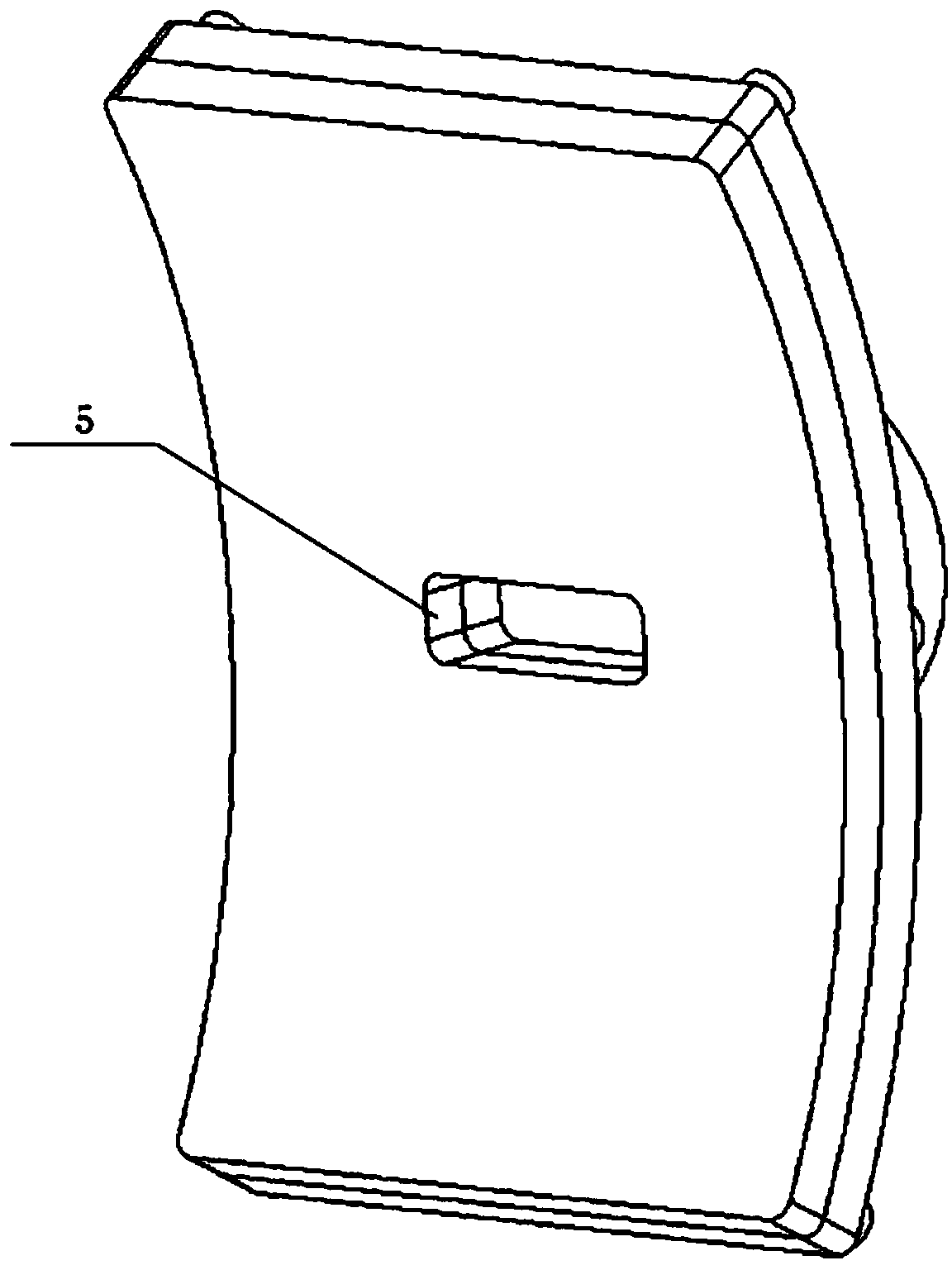

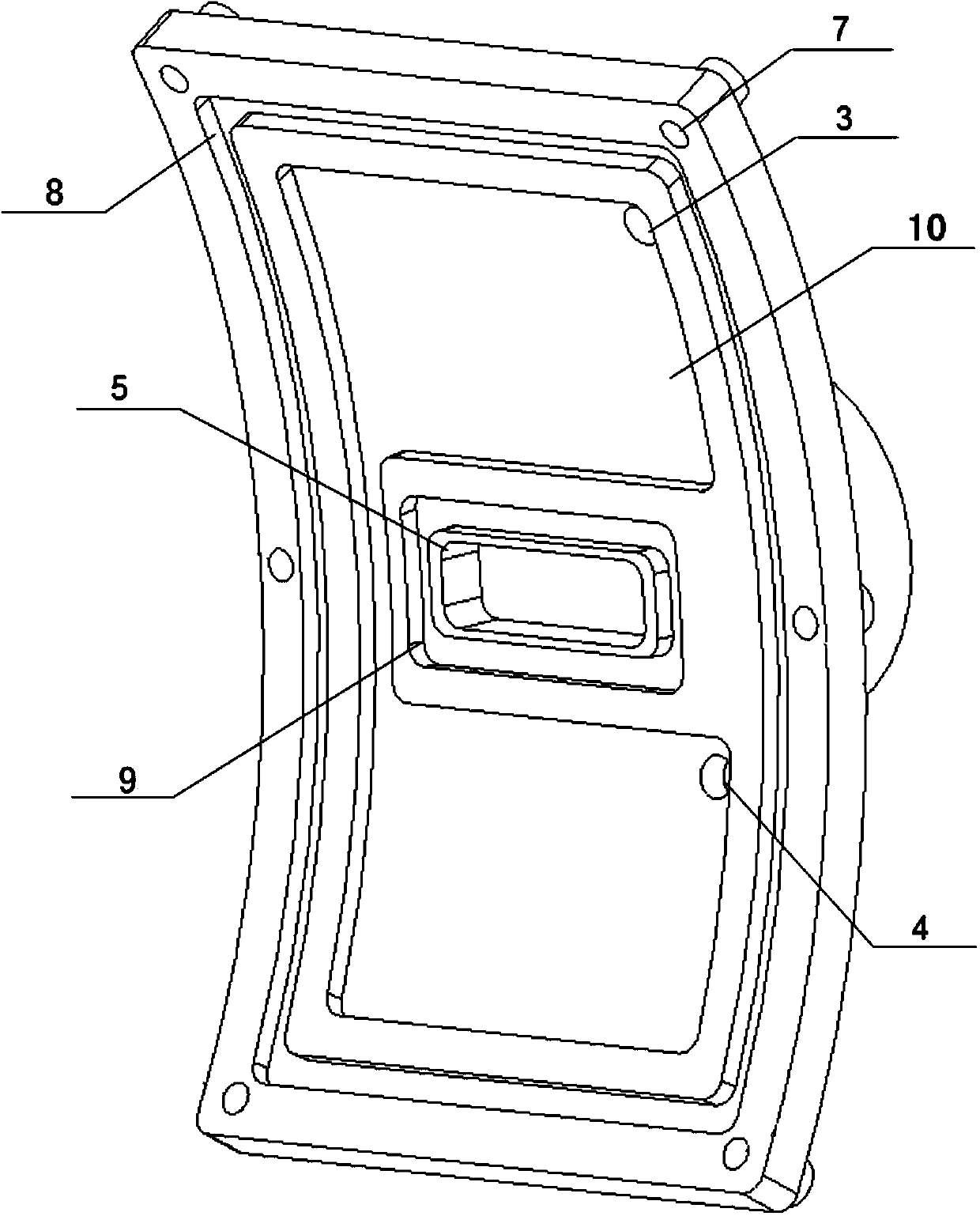

[0012] Such as figure 1 As shown, a special water-cooled reflector for laser processing in this embodiment includes a reflector upper body 1 and a reflector lower body 2. It is characterized in that the reflector upper body 1 is provided with a water-cooled water inlet 3 and a water outlet. 4. The laser beam through hole 5, the internal thread interface 6, the screw hole 7, the upper part of the outer sealing ring groove 8, the upper part of the inner sealing ring groove 9 and the upper part of the water cooling tank 10, wherein the laser beam through hole 5 communicates with the inner thread interface 6, The upper part 10 of the water-cooling tank communicates with the water-cooling water inlet 3 and the water outlet 4. The lower body 2 of the reflector is provided with a laser beam through hole 5, a screw hole 7, a lower part 11 of the outer sealing ring

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap