Baked brick

A technology for sintering bricks and blocks, applied in the field of sintering bricks, can solve the problems of increasing cost, workload and working time, affecting the service life of bank protection, failing to achieve a fixed role, etc., achieving light weight, fast construction progress, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

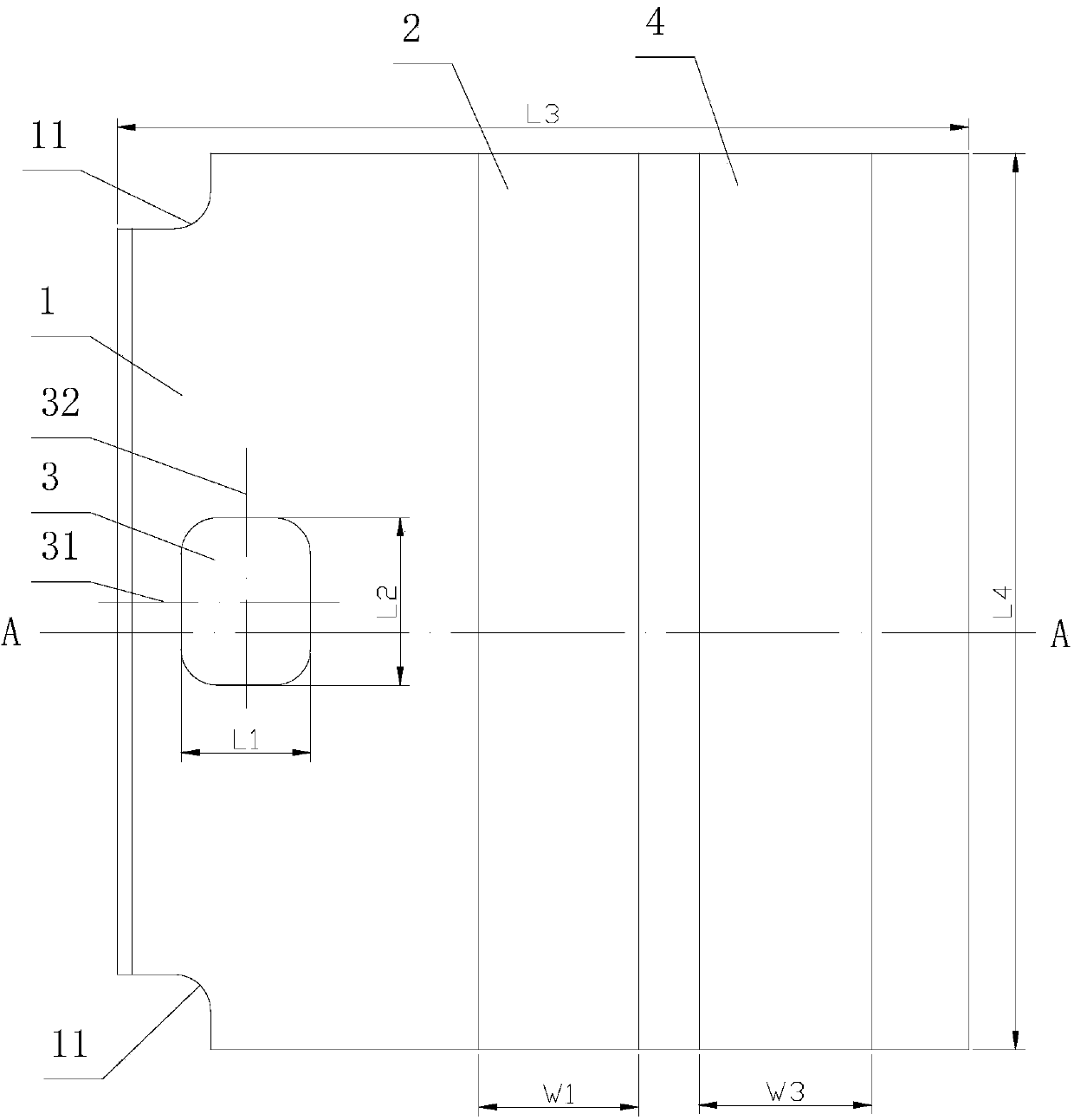

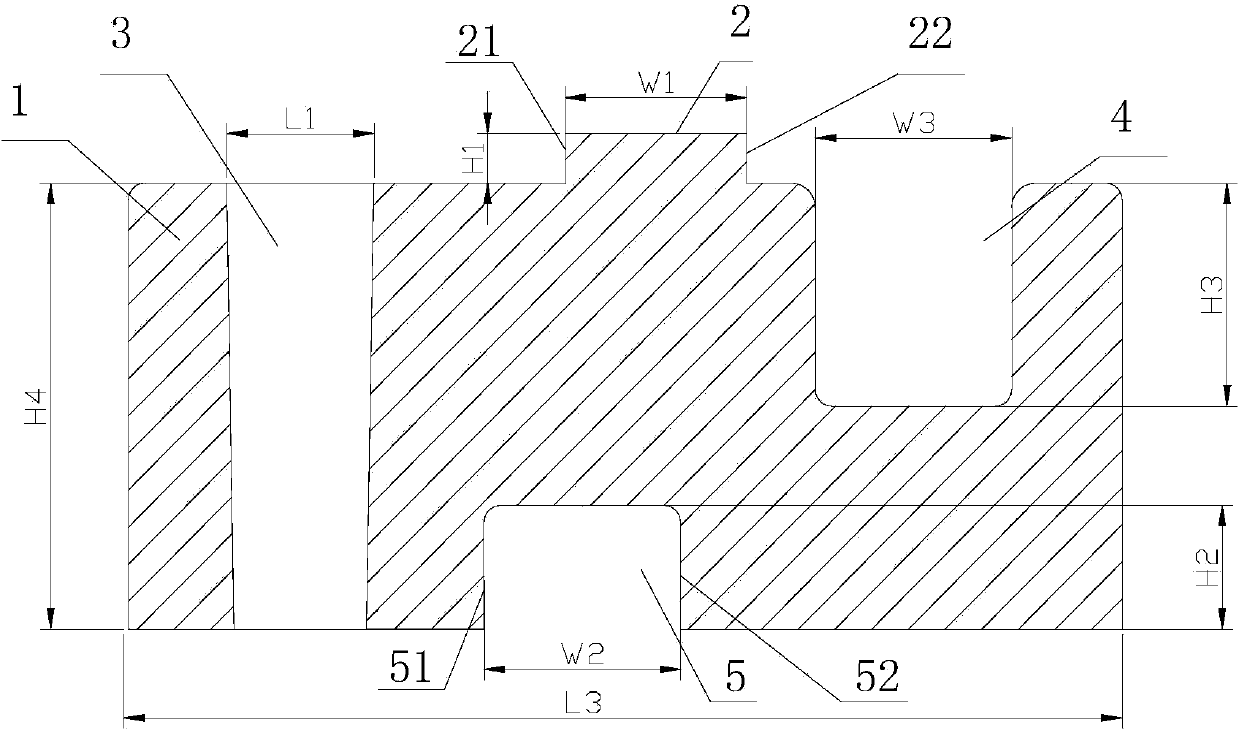

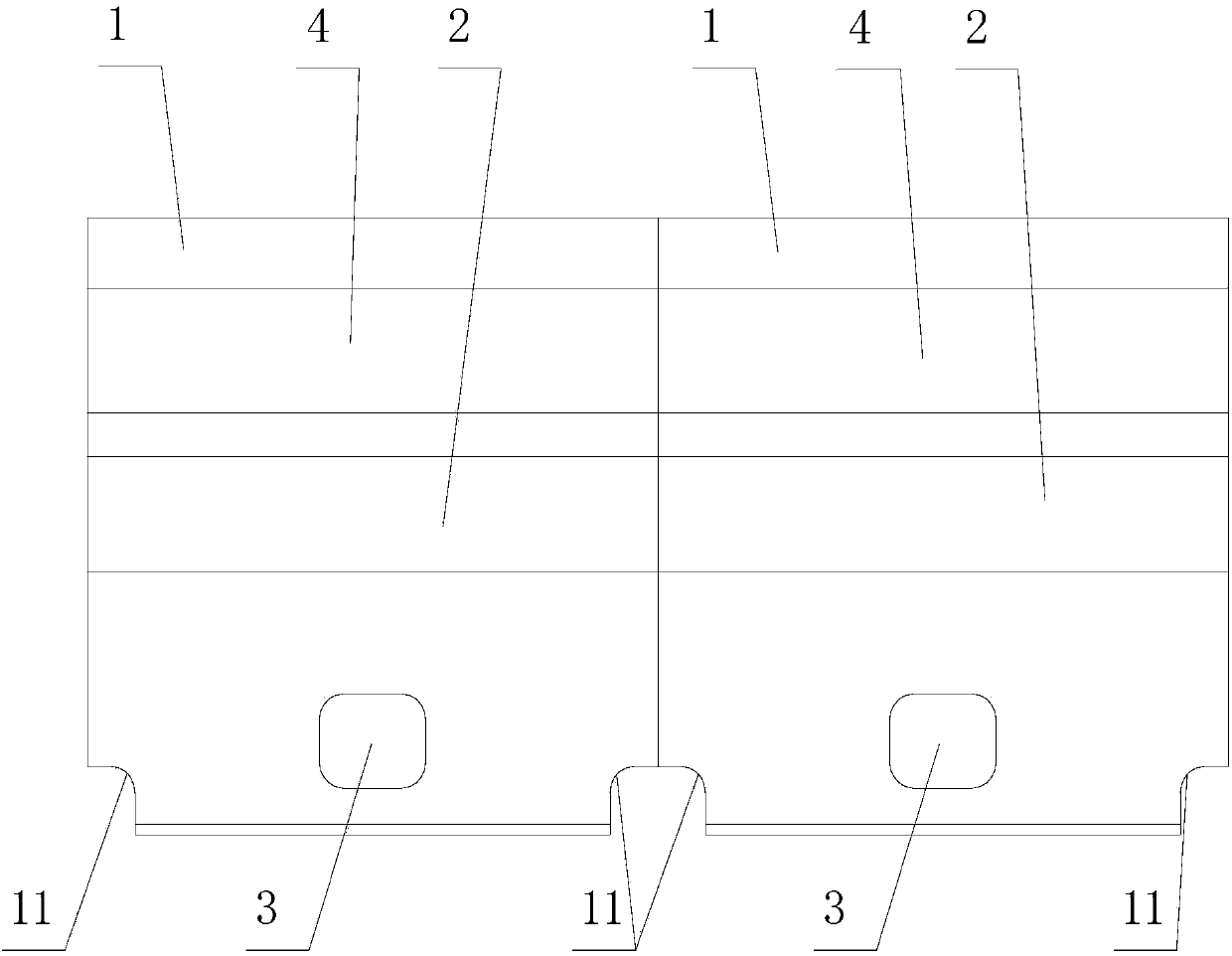

[0027] Such as Figures 1 to 4 As shown, a sintered brick block includes a cuboid body 1, the two corners of the left end of the body 1 are concave to form a gap 11, the upper surface of the body 1 is provided with a long strip-shaped protrusion 2 extending in the front and rear direction, two The gaps 11 are all located on the left side of the protrusion 2, and the upper surface of the body 1 is located on the left side of the protrusion 2. Near the two gaps 11, there are through holes 3 through the upper and lower sides of the body 1, and the upper surface of the body 1 is located on the left side of the protrusion 2. The right side of the body is provided with a strip-shaped through-groove I4, and the through-groove I4 is arranged parallel to the protrusion 2. The lower surface of the body 1 is located on the right side of the through-hole 3. There is a long strip-shaped through-groove II5, and the through-groove II5 is parallel to the protrusion. 2, the through groove II5 and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap