Lamp assembly structure

A technology for assembling structure and lamp body, which is applied to lighting devices, lighting device parts, light sources, etc., can solve the problems of inconvenient assembly, disassembly and automated production, and complex LED lighting ceiling spotlight processes, and achieves easy disassembly. And the effect of automatic production, simple structure and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

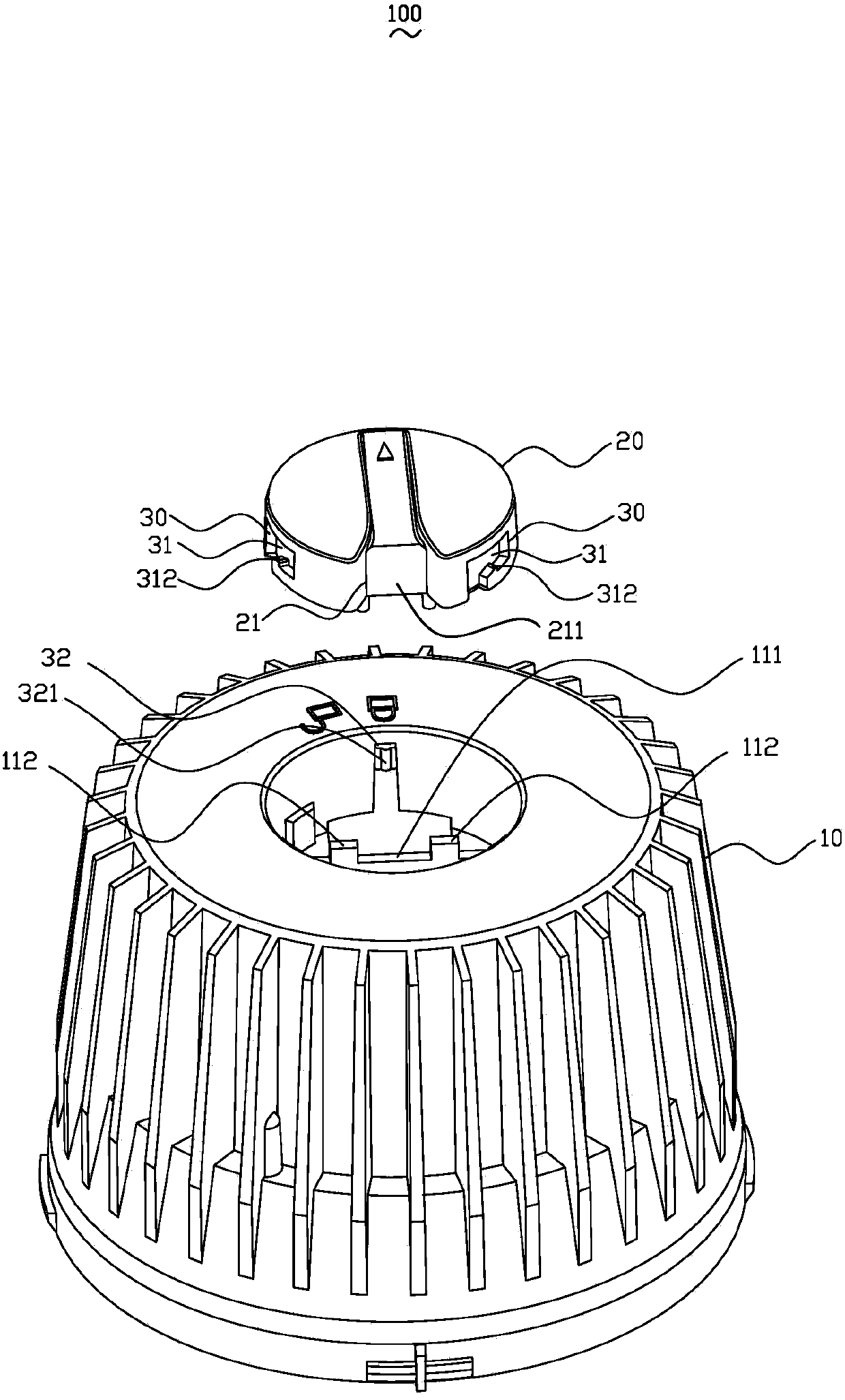

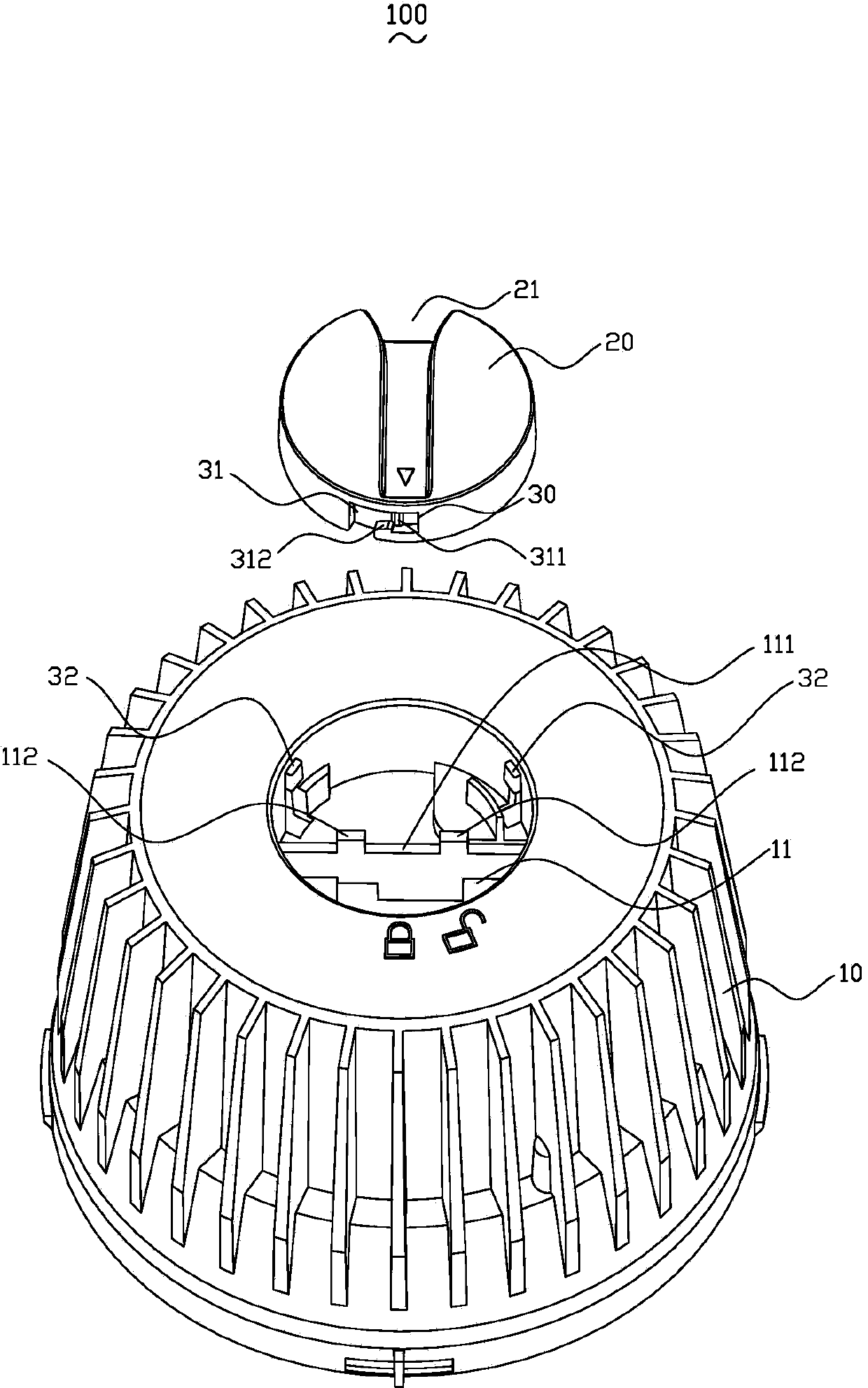

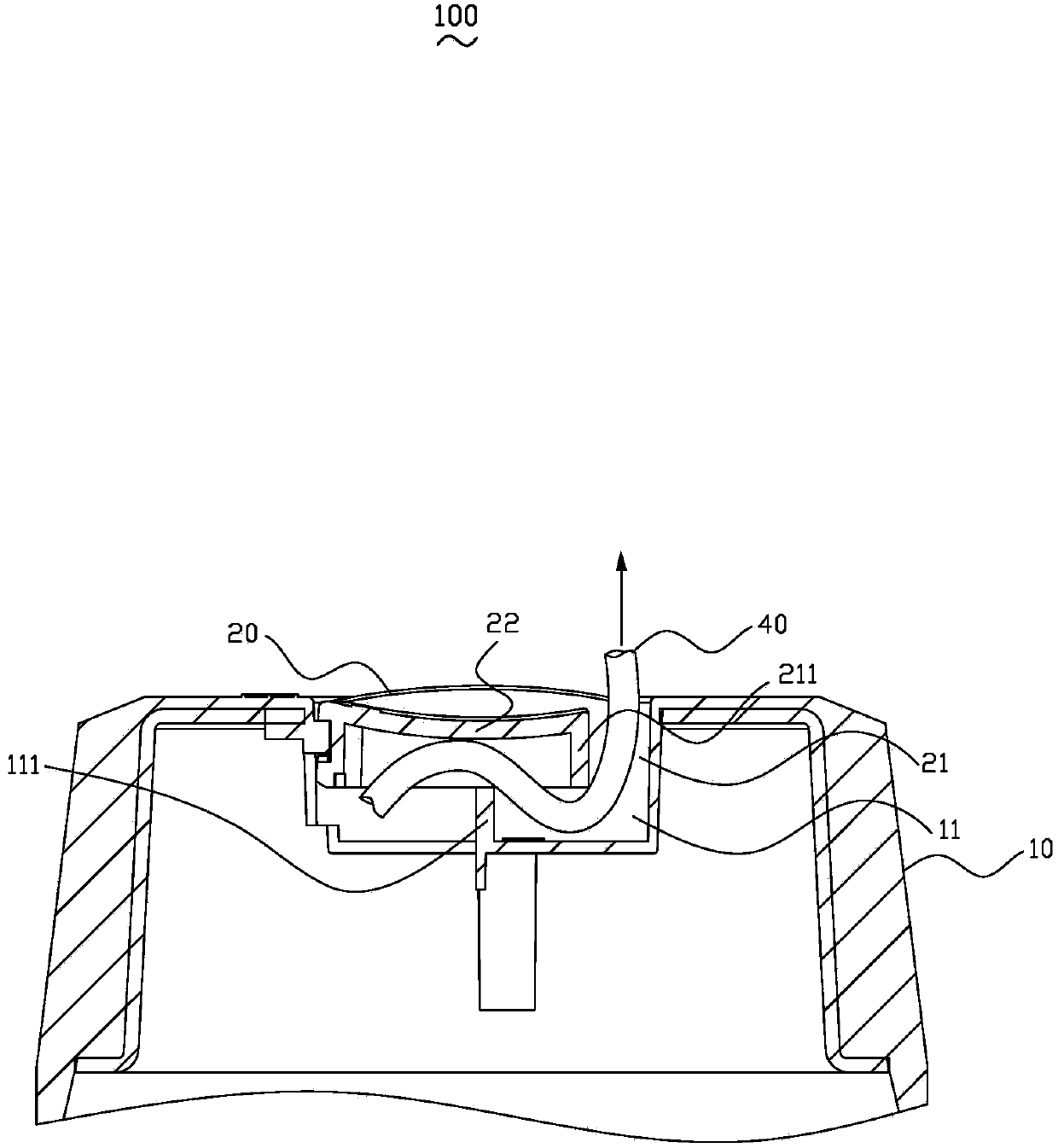

[0016] Please refer to Figure 1 to Figure 3 , the lamp body assembly structure 100 includes a lamp body 10, an upper cover 20, a turnbuckle structure 30 and an electric wire 40, the lamp body 10 is provided with a receiving groove 11 for accommodating the upper cover 20, and the upper cover 20 passes through the turnbuckle The structure 30 is buckled in the receiving groove 11 , the upper cover 20 is provided with a through hole 21 , and the wire 40 passes through the through hole 21 and extends out of the lamp head body 10 .

[0017] Please refer to Figure 1 to Figure 3 , the top of the lamp holder body 10 is provided with a receiving groove 11 . The bottom surface of the receiving groove 11 is provided with a limit bar 111, and the limit bar 111 deviates from the through hole 21 of the upper cover 20 in the vertical direction (such

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap