Plug-pull-type fast lock for gauge board box cover

A plug-in, machine box technology, which is applied in the direction of building fastening devices, buildings, building structures, etc., can solve the problems of short service life, weakened elasticity, easy deformation, etc., and achieve long service life and stable clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

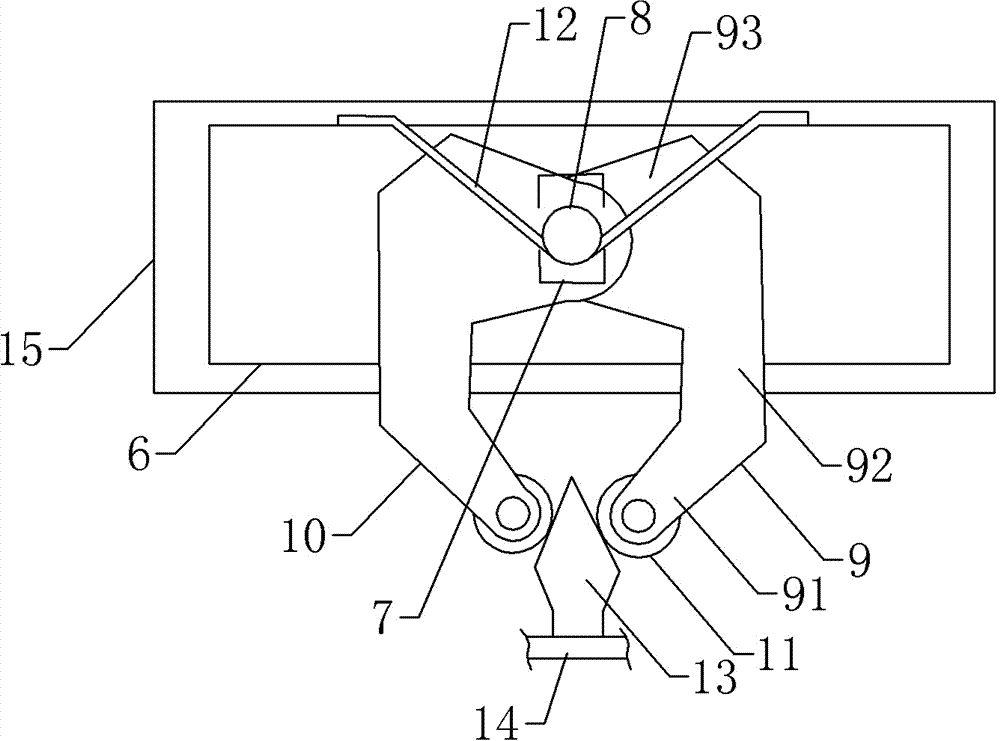

[0016] like figure 2 The shown plug-in quick lock for the instrument box cover includes a lock table 6, a slide hole 7, a support shaft 8, a first jaw 9, a second jaw 10, a guide roller 11, a torsion spring 12 and The dead bolt 13 and the lock platform 6 are arranged inside the instrument case 15 , and the dead bolt 13 is arranged on the inner side of the box cover 14 .

[0017] Both the first jaw 9 and the second jaw 10 include a connecting portion 93, a transition portion 92 and a clamping portion 91, the connecting portion 93, the transition portion 92 and the clamping portion 91 are in a “U” shape, and the first jaw 9 and The "U"-shaped openings of the second jaws 10 are opposite to each other. The lock table 6 is provided with a vertical slide hole 7, and the support shaft 8 is arranged in the slide hole 7 and has a vertical degree of freedom. The slide hole 7 plays a guiding role for the support shaft 8. Both the connecting parts 93 of the first jaw 9 and the second jaw

Embodiment 2

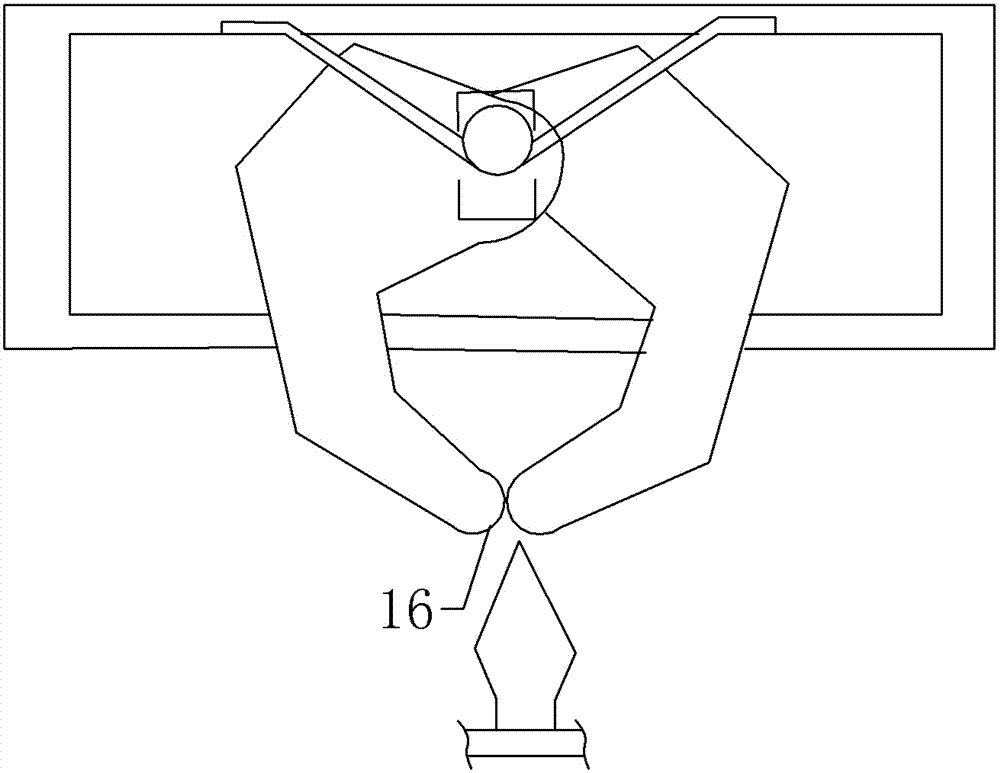

[0022] like image 3 As shown, when the lock tongue is not inserted into the clamping part, the clamping part of the first clamping jaw and the second clamping jaw are in contact. The only difference between this embodiment and the first embodiment is that the first clamping jaw and the second clamping jaw The outer ends of the clamping parts of the two jaws are all cylindrical curved surfaces 16 . The structural design of the cylindrical curved surface also guides the bolt.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap